Natural gas filter

A natural gas and filter technology, applied in the direction of dispersed particle filtration, gas fuel, chemical instruments and methods, etc., can solve the problems of gas outlet pipe fittings deposition, pressure regulating valve damage, complicated operation, etc., achieve simple cleaning methods and improve cleanliness , Improve the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

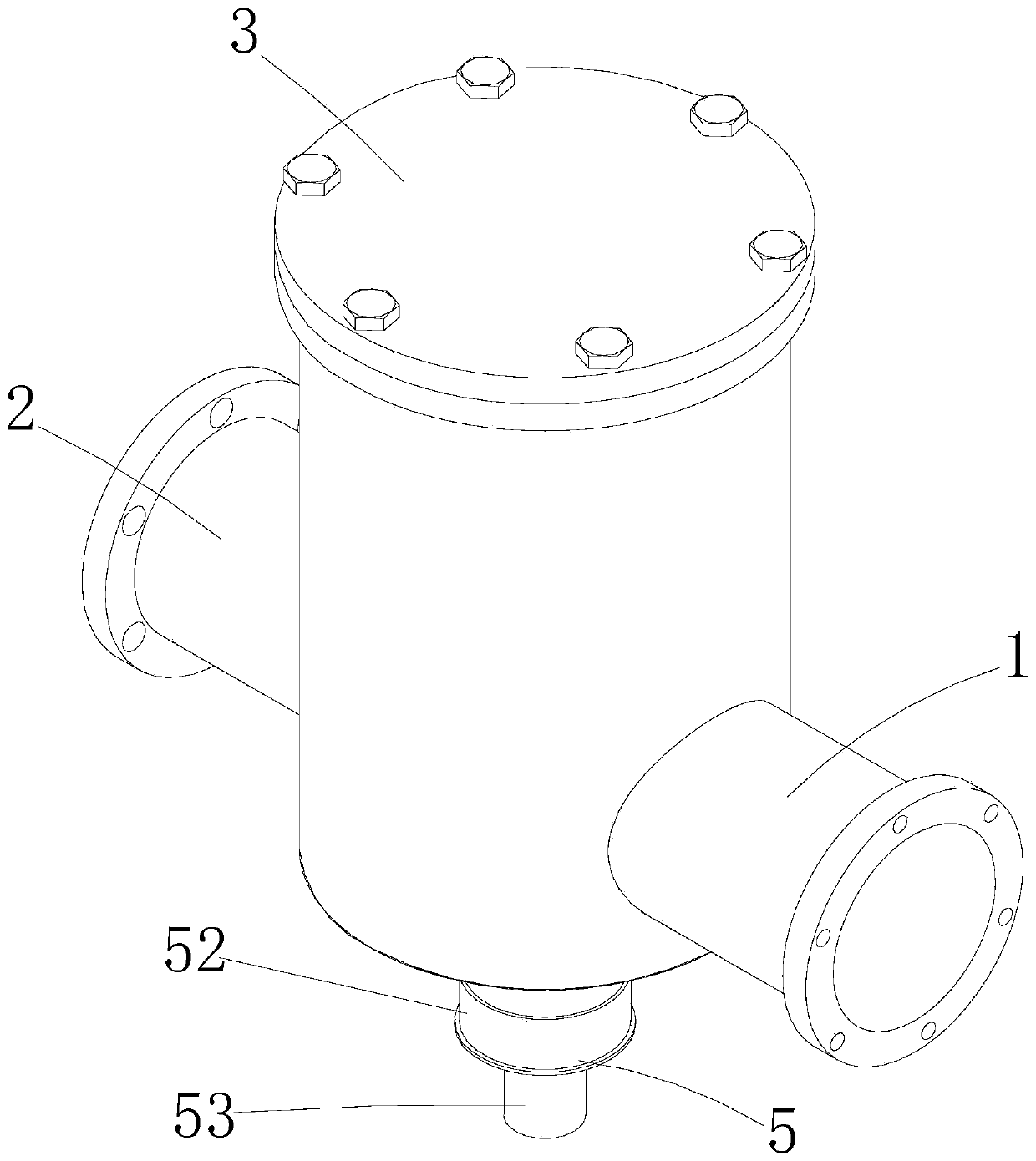

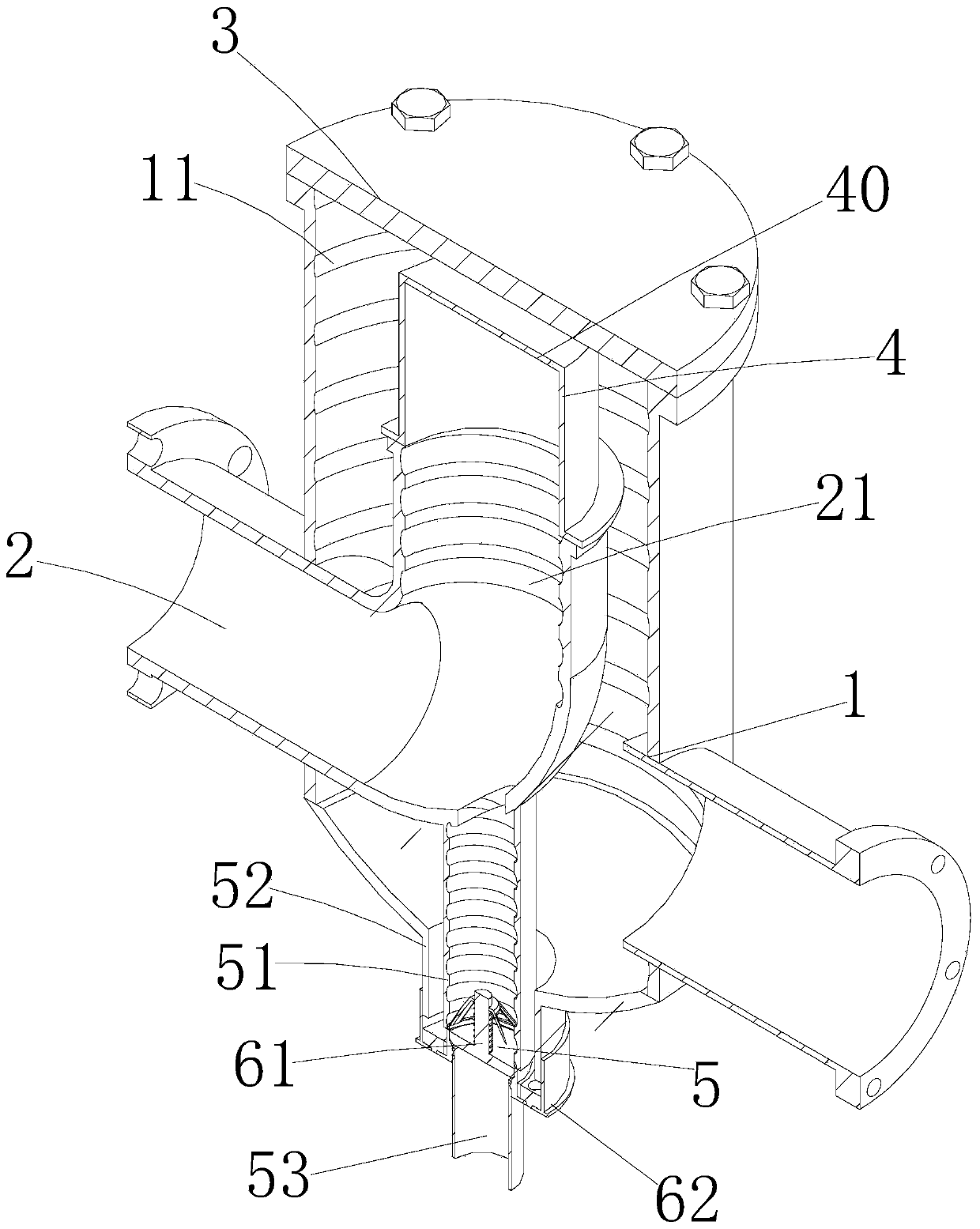

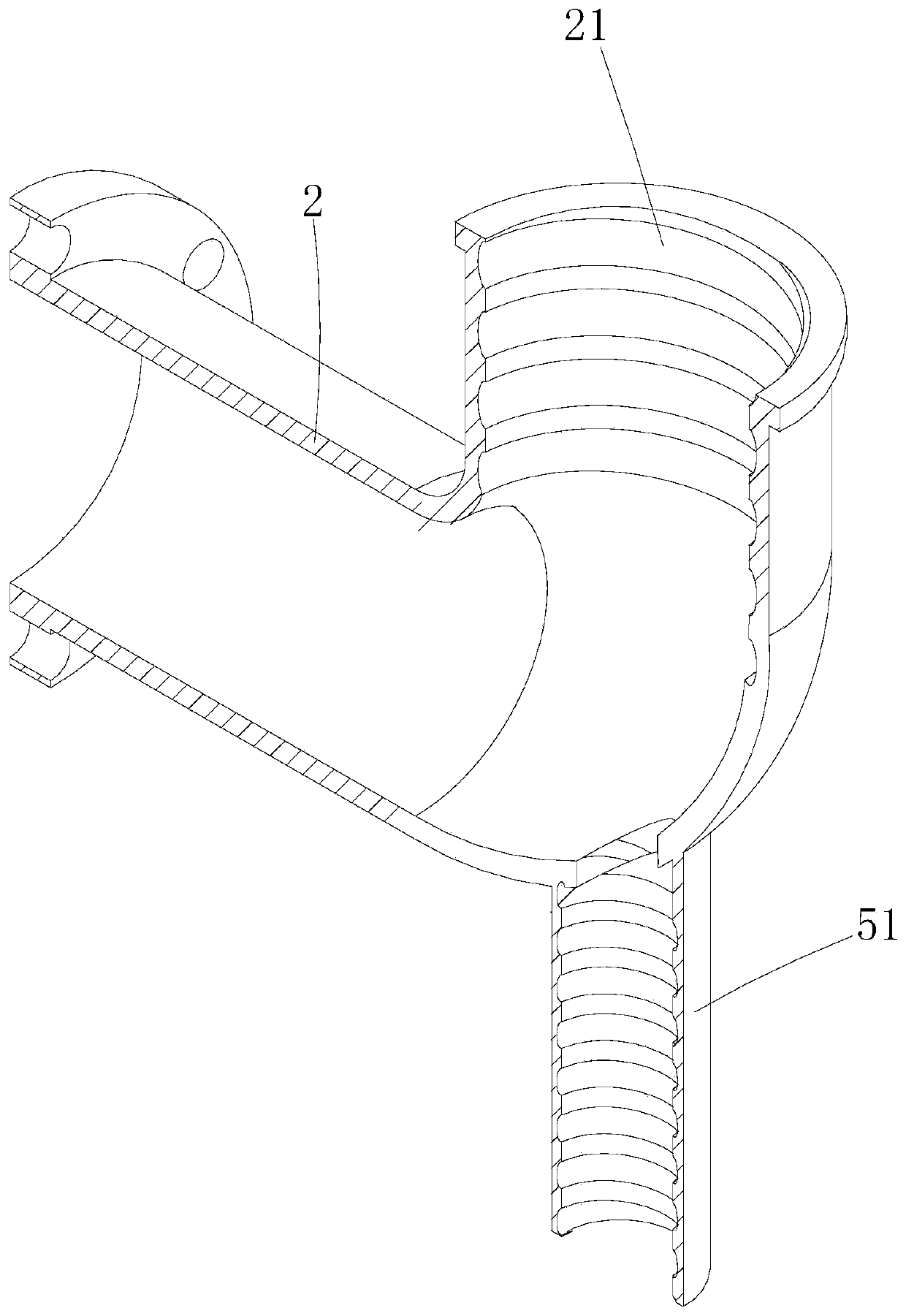

[0032] Such as Figure 1-9 As shown, a natural gas filter includes an air intake pipe fitting 1, an air outlet pipe fitting 2, a cover plate 3, a filter structure 4 and a sewage discharge structure 5, the air intake pipe fitting 1 is an L-shaped metal pipe, and unfiltered natural gas flows from Into the middle of the air intake pipe 1, a second helical groove 11 is provided on the inner wall of the air intake pipe 1, and the second helical groove 11 is a threaded groove formed on the air intake pipe 1. ; The outlet pipe part 3 is also a metal pipe, and the outlet pipe part 2 is also an L-shaped metal pipe. The first spiral groove 21 is provided on the top, and the first spir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com