Water conservancy engineering pipeline outer surface rust removal device with positioning performance

A technology for water conservancy engineering and external surfaces, which is applied to cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

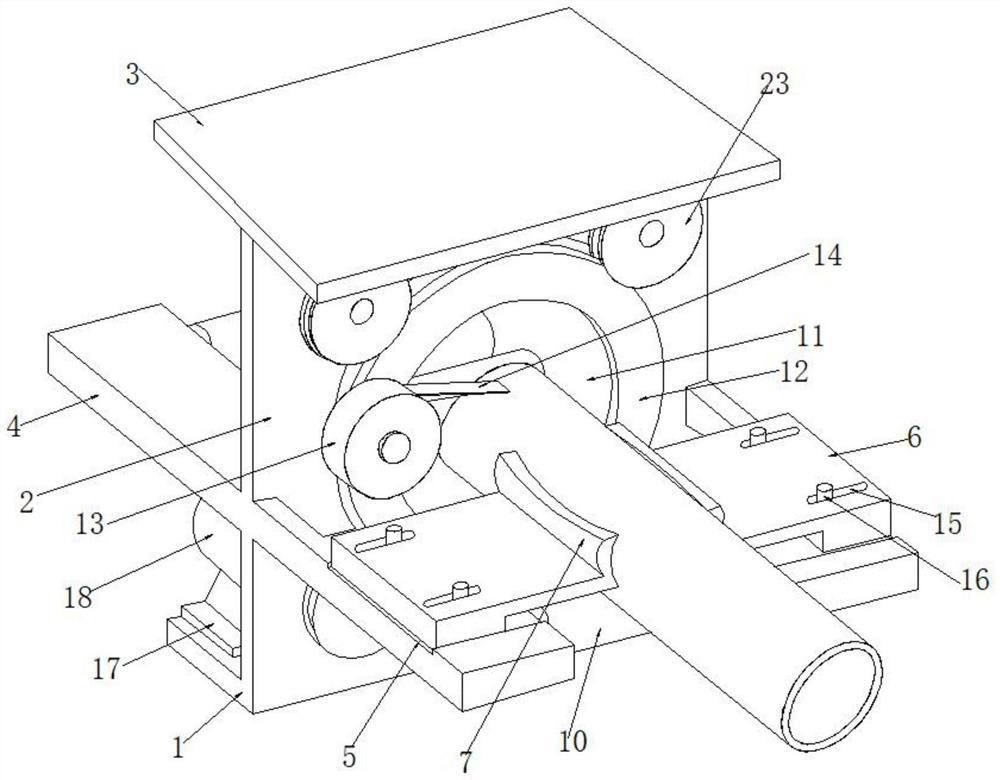

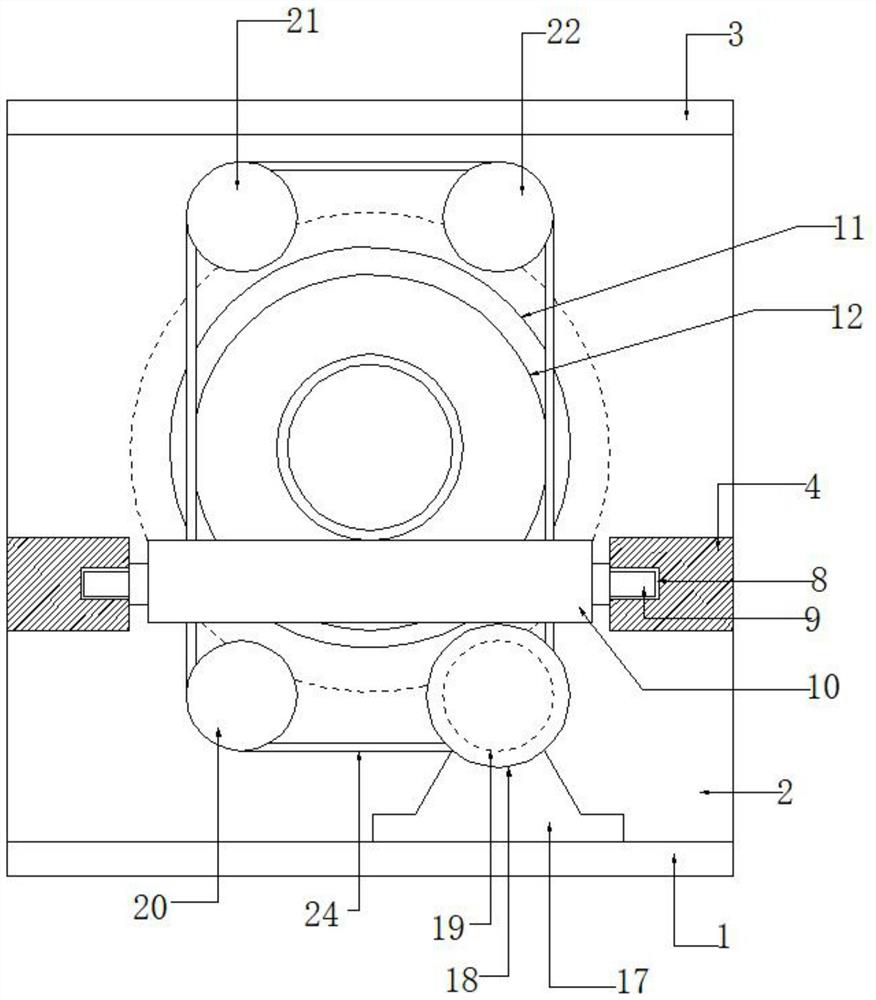

[0031] Such as Figure 1-4 displayed in:

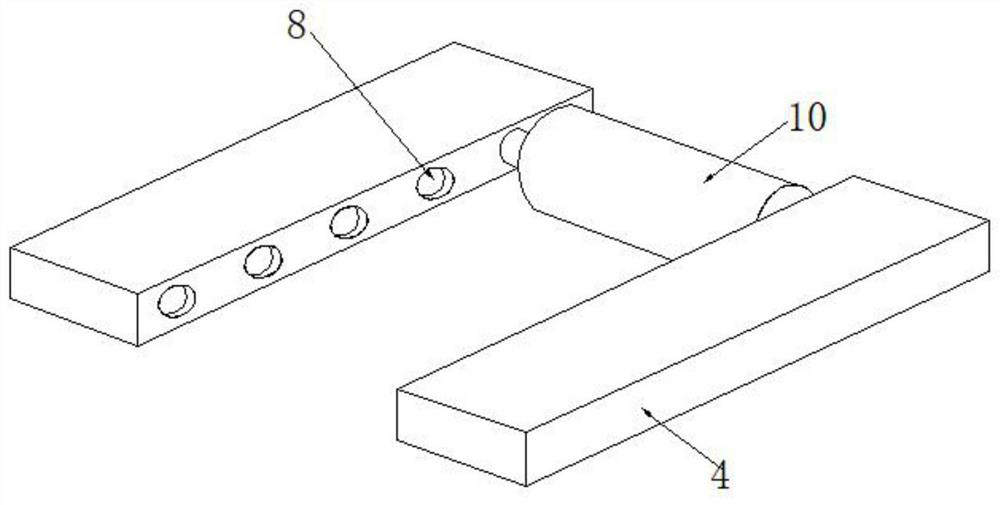

[0032]The present invention provides a positioning rust removal device for the outer surface of water conservancy pipelines, the structure of which includes a support base 1, a support plate 2 is provided on one side of the support base 1, and a top plate is provided on the top of the support plate 2 3. The two ends of the middle part of the support plate 2 are clamped with a fixed plate 4, and the outer end of one side of the fixed plate 4 is provided with a chute 5, and the chute 5 is provided with the chute 5. For the matching slide plate 6, symmetrical splints 7 are provided on the corresponding side ends of the slide plates 6 at both ends, and the pipe body is clamped between the splints 7 at both ends, and a number of splints are provided on the corresponding sides of the fixed plates 4 at both ends. Groove 8, the roller shaft 9 that is suitable for described groove 8 is all inserted in described groove 8, and roller 10 is all ...

Embodiment 2

[0036] Such as figure 1 and Figure 5 displayed in:

[0037] The present invention provides a positioning rust removal device for the outer surface of water conservancy pipelines, the structure of which includes a support base 1, a support plate 2 is provided on one side of the support base 1, and a top plate is provided on the top of the support plate 2 3. The two ends of the middle part of the support plate 2 are clamped with a fixed plate 4, and the outer end of one side of the fixed plate 4 is provided with a chute 5, and the chute 5 is provided with the chute 5. For the matching slide plate 6, symmetrical splints 7 are provided on the corresponding side ends of the slide plates 6 at both ends, and the pipe body is clamped between the splints 7 at both ends, and a number of splints are provided on the corresponding sides of the fixed plates 4 at both ends. Groove 8, the roller shaft 9 that is suitable for described groove 8 is all inserted in described groove 8, and roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com