Method for producing putty powder by using fly ash as raw material

A technology for fly ash and raw materials, applied in chemical instruments and methods, filling slurry, magnetic separation, etc., can solve the problems of large historical stock and low utilization rate, and achieve improved reaction rate, high production efficiency, and reduced production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

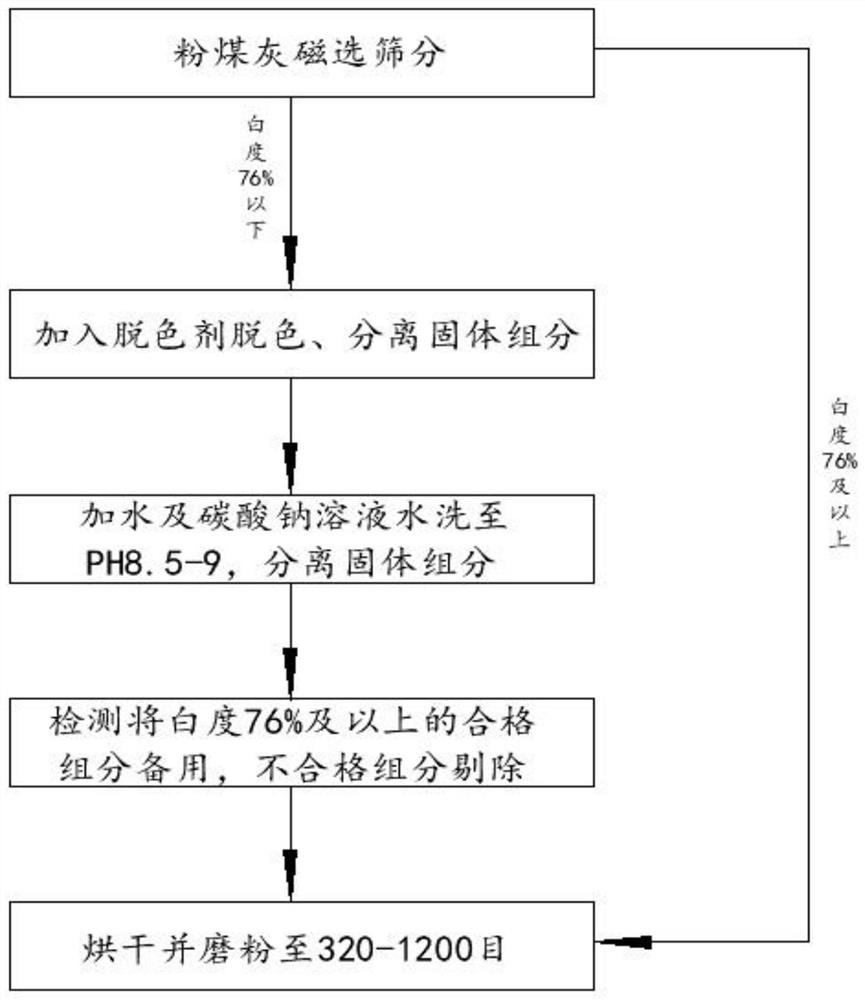

[0025] like figure 1 The method shown in the production of a pour as a raw material is prepared in the production of putty powder, and the following steps are specifically including the following steps:

[0026] Step 1: In order to be able to blow the drum, the magnetic selection screening efficiency of the fly ash and the magnetic selection screening effect, and to separate the different components, the prepared fly ash will be delivered through the airflow to the belt In the five-stage vibrating screen of the iron facility, the iron screening is performed. In order to collect different components of the screen, the five-stage vibrating screen is provided with separate settlement collection bins, according to the water content of the water content in the fly ash. 75 ° C, according to the collecting component of the collecting bin, 25 m / s, according to the particle size distribution value in the collection bin, control the fly ash and the airflow volume ratio of 1.5: 100, so tha...

Embodiment 2

[0032] The present embodiment differs from the first embodiment in that the gas flow temperature is 62 ° C, the gas flow rate 17m / s, the fly ash and the gas stream is 1.1: 100; the concentration of the dilute hydrochloric acid in step b is 0.2%. The solid content in the reaction mixture is 12%, the mixing paddle rotational speed 65 rpm, the decolorization reaction is 2 hours; the water is controlled at the time of water washing in step three, and the solid content is 15%, stirred by 65 rpm, medium and pH 8.5. Wash the deionized water; step 5, in step five, polishing it to fineness 320 according to quality standards and demand with users.

Embodiment 3

[0034] The present embodiment differs from Examples 1, 2 in that the gas flow temperature is 69 ° C, the airflow flow rate 21 m / s, the fly ash and the gas stream is 1.3: 100; the concentration of the dilute hydrochloric acid in step b is 0.9%, the solid content in the reaction mixture was 19%, stirred by 75 rpm, and the decolorization reaction was 4 hours; the water was washed in step three to control the solid content of 23%, stirred with a paddle rotation of 75 rpm, medium and pH8 .7, deionized water is washed twice; step five, according to quality standards and the demand for users, it is 760 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com