Industrial polishing brush for plate processing

A plate processing and polishing brush technology, applied in metal processing equipment, surface polishing machine tools, grinding/polishing equipment, etc., can solve the problems of uneven polishing of metal plate surface, reduced practicability, and reduced polishing effect of metal plate surface , to achieve the effect of improving the polishing effect, extending the service life, improving the effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

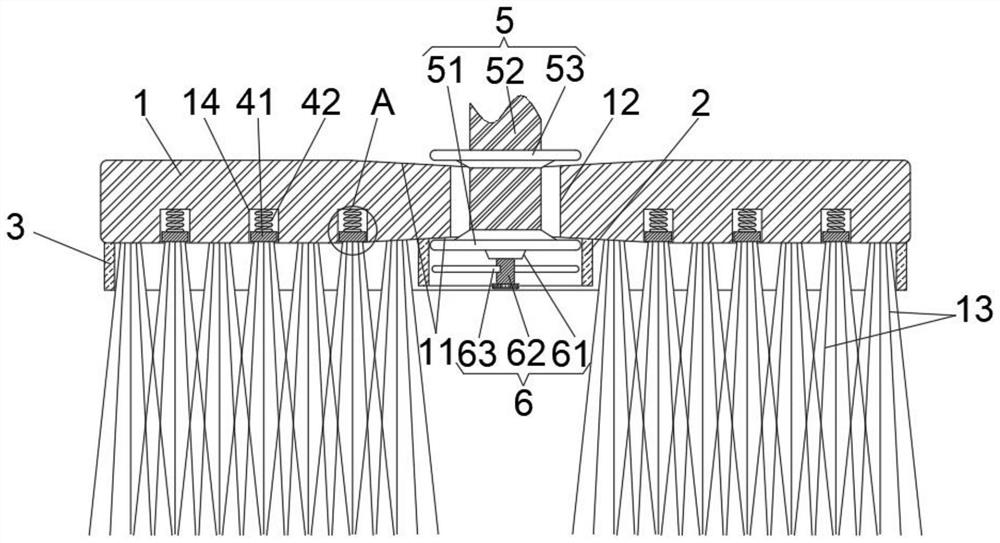

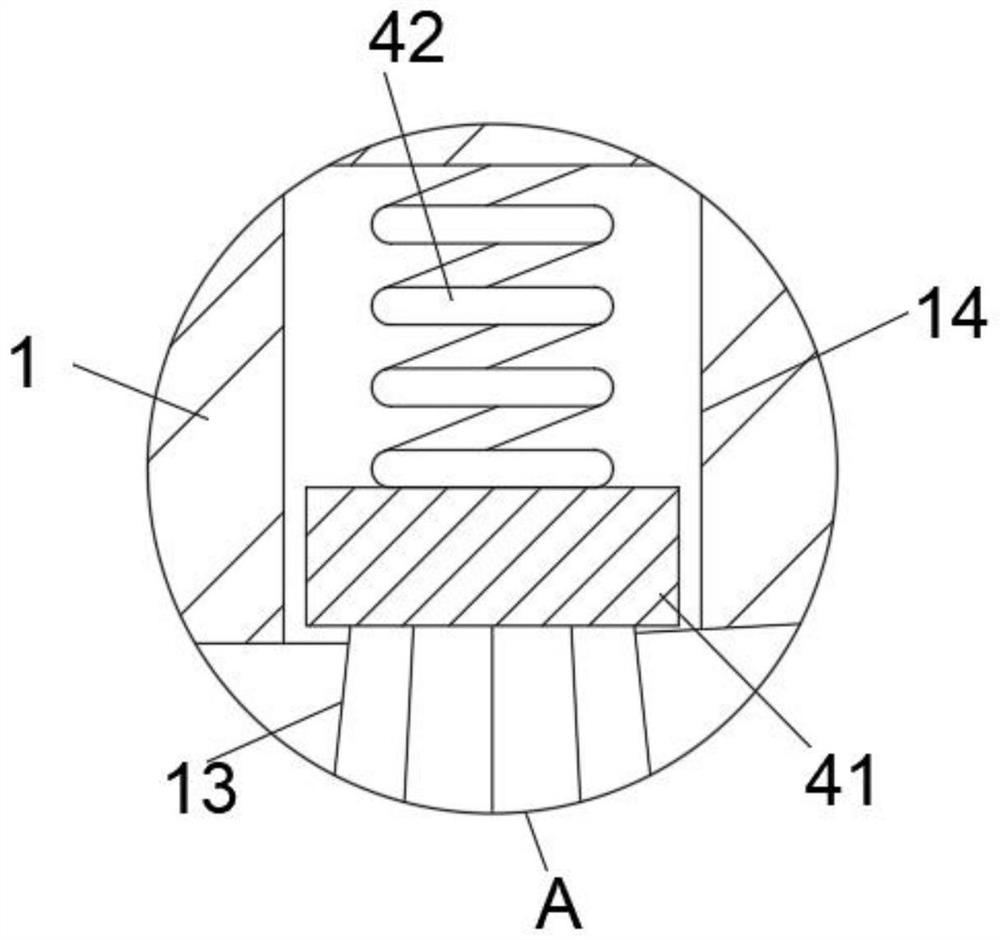

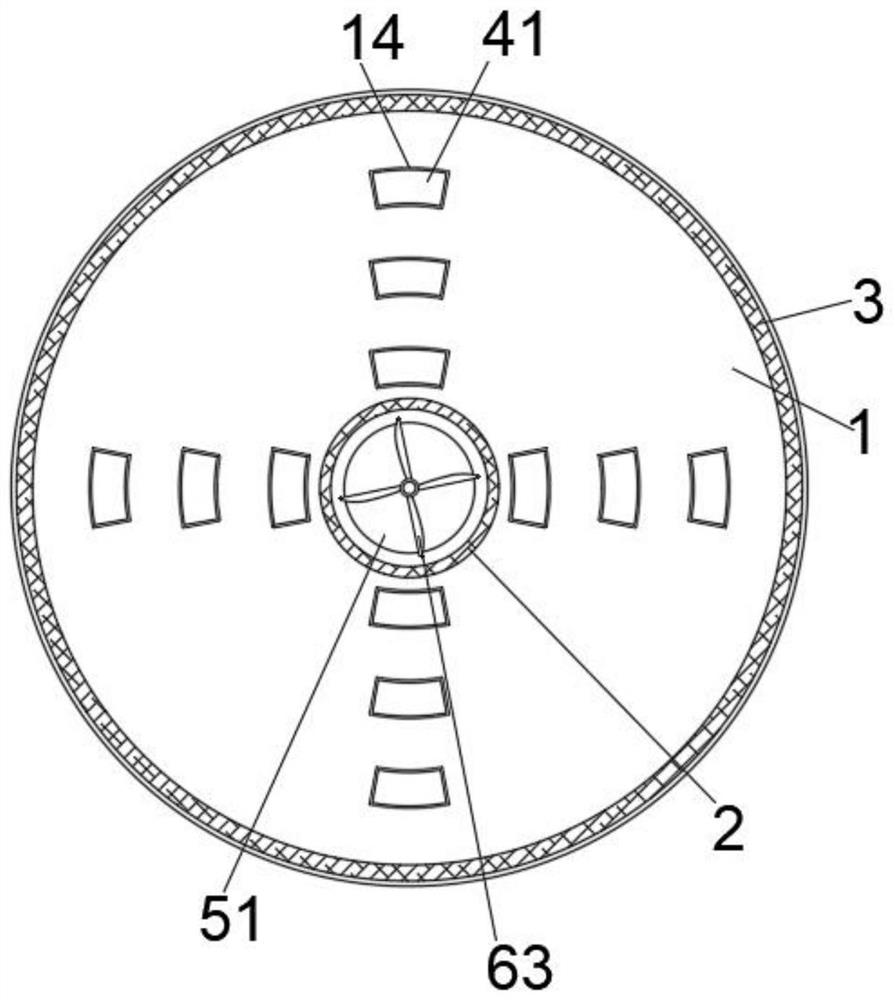

[0021] see Figure 1-3 As shown, the present invention provides a technical solution for industrial polishing brushes for plate processing: including the brush plate 1 and the adapter groove 14 provided on the ground of the brush plate 1, the adapter groove 14 is evenly distributed in a circumferential shape, and the adapter groove 14 is equipped with There is an adjustment component, which makes the polishing brush more suitable for the polishing operation of the metal plate surface with bumps. The middle part of the brush plate 1 is provided with a mounting mechanism 5, and the mounting mechanism is used for fast and stable assembly of the polishing brush. The bottom of the mechanism 5 is provided with a dust removal mechanism 6, which is used to effectively blow off the dust generated in the polishing operation, thereby further improving the polishing effect;

[0022] The adjustment assembly includes an adjustment block 41, the adjustment block 41 is slidably connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com