Single crystal furnace dedusting and filtering system

A filter system and single crystal furnace technology, applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of affecting dust removal effect, exhaust pipe blockage, difficult to remove, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

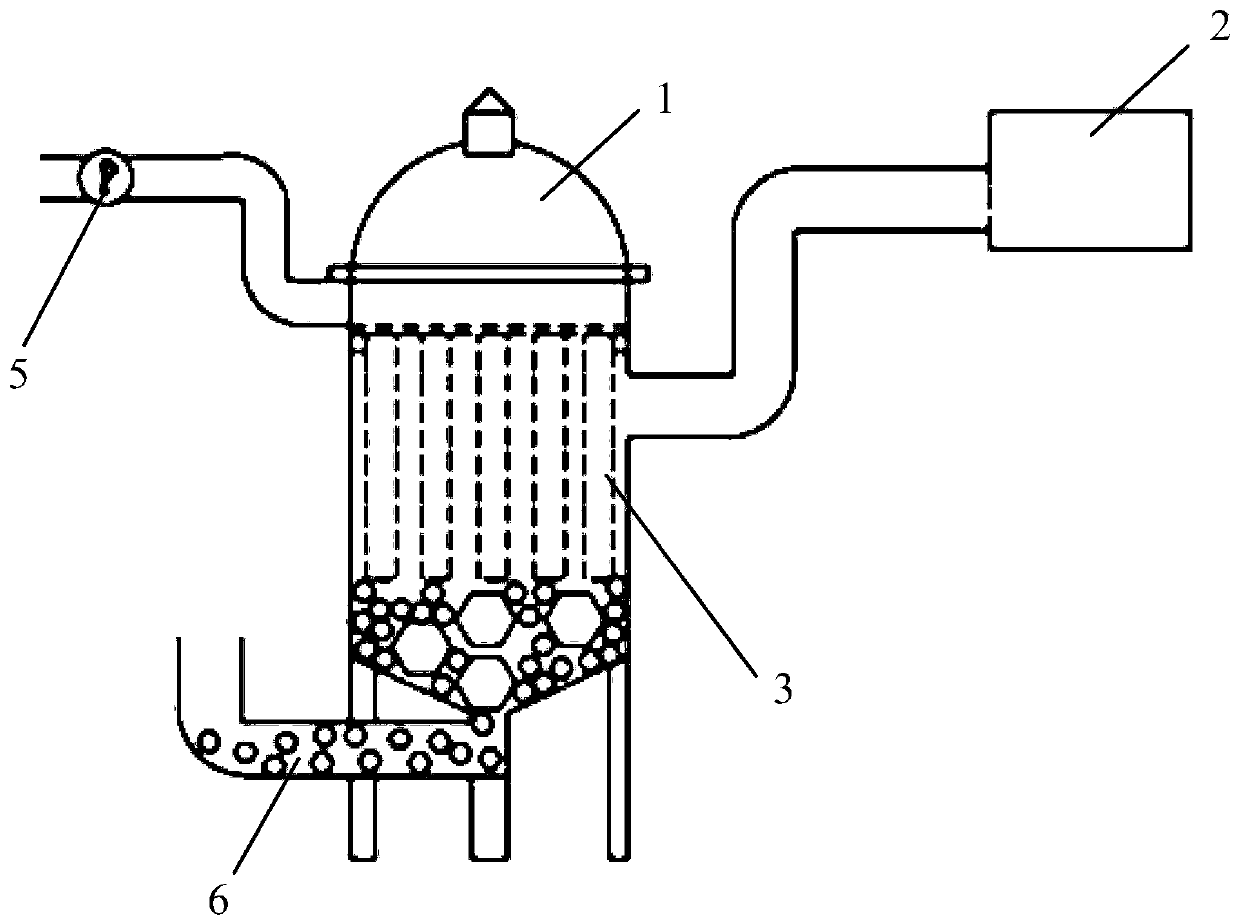

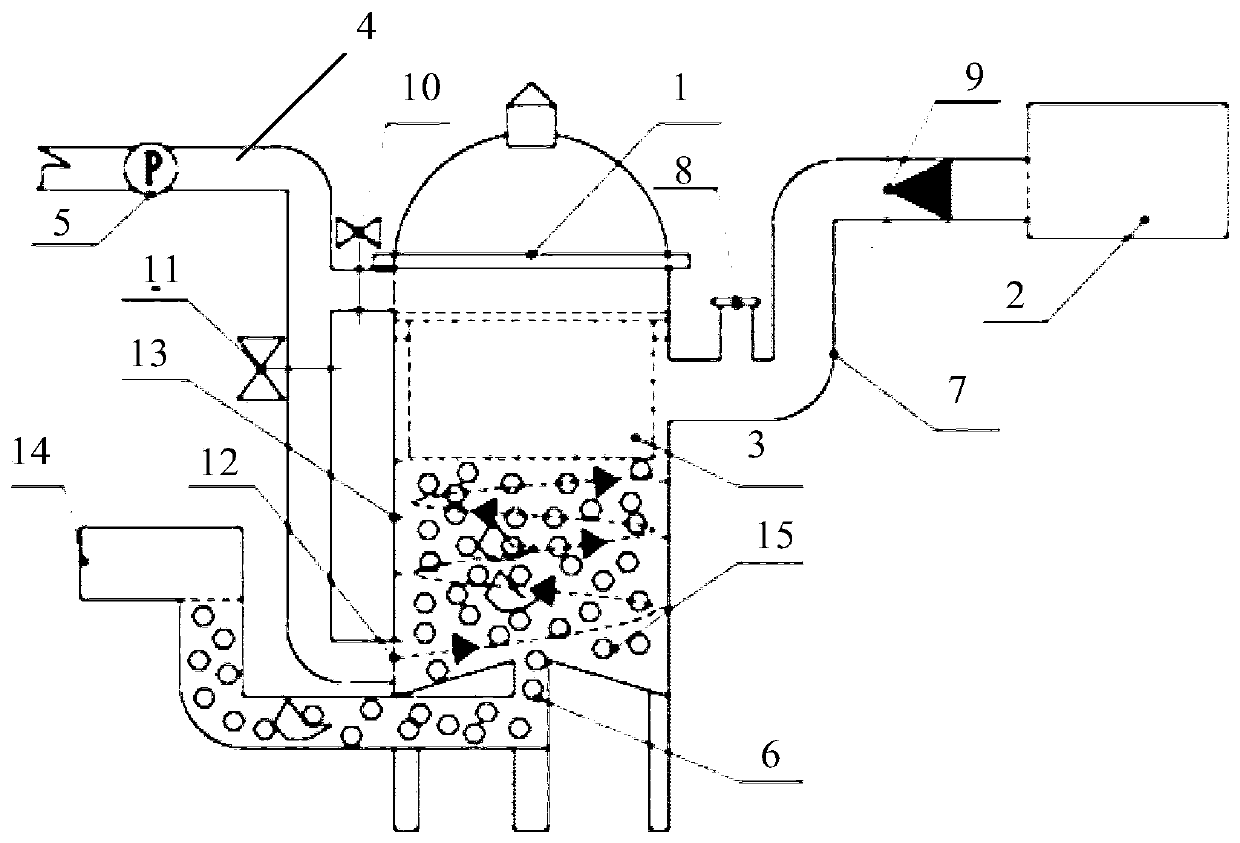

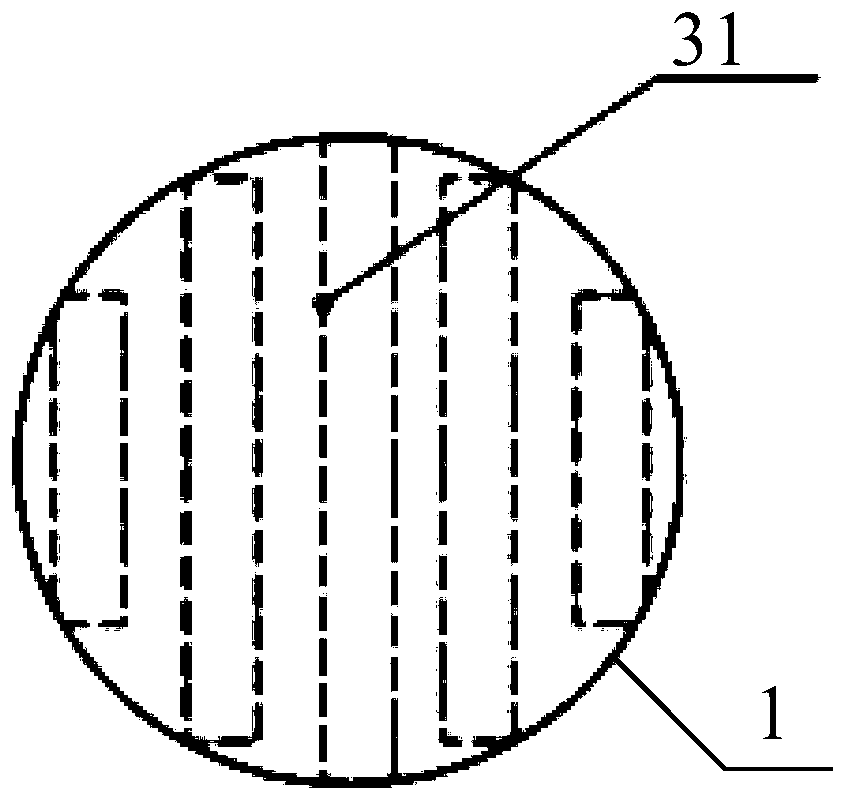

[0036] See figure 2 , figure 2 It is a schematic structural diagram of a single crystal furnace dust removal and filtration system provided by an embodiment of the present invention. The single crystal furnace dust removal filtration system includes a dust removal tank main body 1 and a vacuum pump assembly, wherein the dust removal tank main body 1 is in communication with the single crystal furnace 2, and the dust removal tank main body 1 is provided with a filter unit 3 inside; the vacuum pump assembly includes a vacuum pipeline 4 and a set The vacuum pump 5 on the vacuum pipeline 4 and the vacuum pipeline 4 communicate with the main body 1 of the dust removal tank. The vacuum pump assembly is used to vacuum the inner cavity of the dust removal tank body 1 when the single crystal furnace 2 is pulling crystals, so as to remove the impurity gas inside the single crystal furnace 2, and to clean the dust removal tank body 1 when the single crystal furnace 2 finishes crystal pul...

Embodiment 2

[0049] On the basis of the foregoing embodiment, this embodiment provides another single crystal furnace dust removal and filtration system. See Figure 7 , Figure 7 It is a schematic structural diagram of another single crystal furnace dust filter system provided by an embodiment of the present invention. The single crystal furnace dust removal and filtration system of this embodiment includes a vacuum pump assembly and two parallel dust removal tank main bodies 1, wherein each dust removal tank main body 1 is connected to a different single crystal furnace, and each dust removal tank main body 1 is provided with a filter inside. Unit, each dust removal tank body 1 is used for dust removal and filtration of a separate single crystal furnace. The vacuum pump assembly of this embodiment includes a vacuum pipe 4 and a vacuum pump 5 arranged on the vacuum pipe 4, and the vacuum pipe 4 is in communication with two dust removal tank bodies 1 at the same time. Similarly, the vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com