Folding separate machine of non-woven tablecloth

A technology of non-woven fabrics and splitting machines, which is applied in packaging machines, packaging, transportation and packaging, etc., which can solve problems such as equipment failure, circuit board burnout, and failure of heat treatment to prevent circuit boards from working normally , Improve the effect of heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

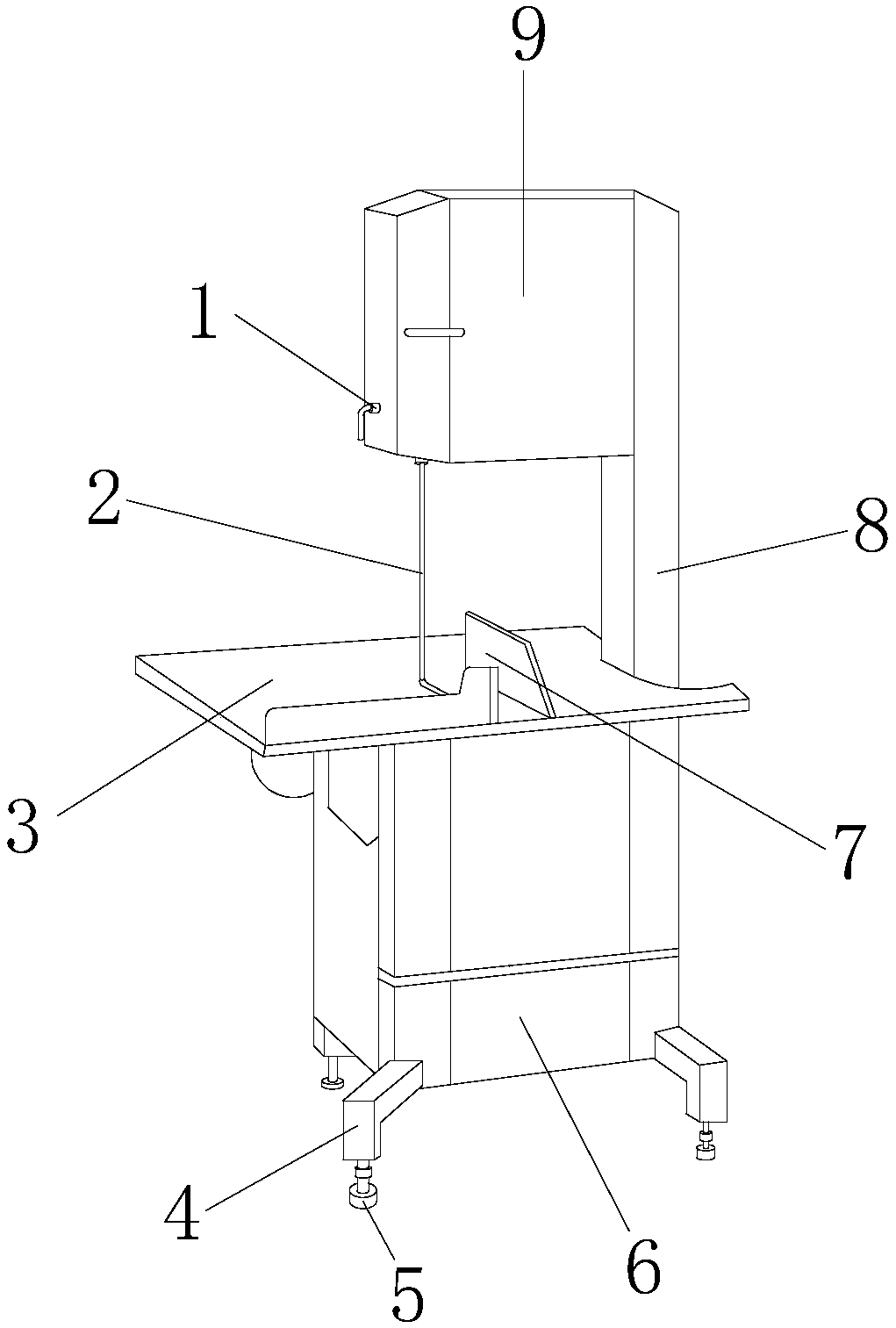

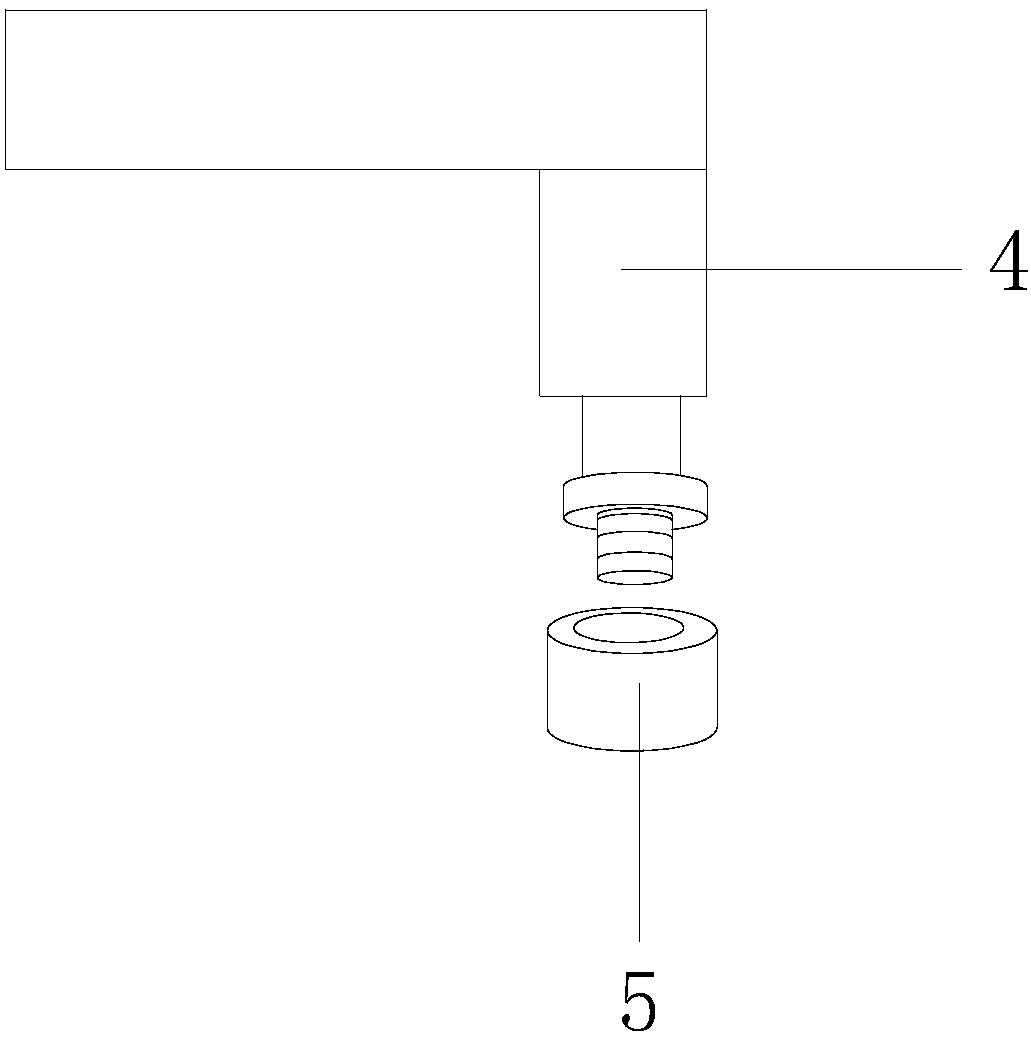

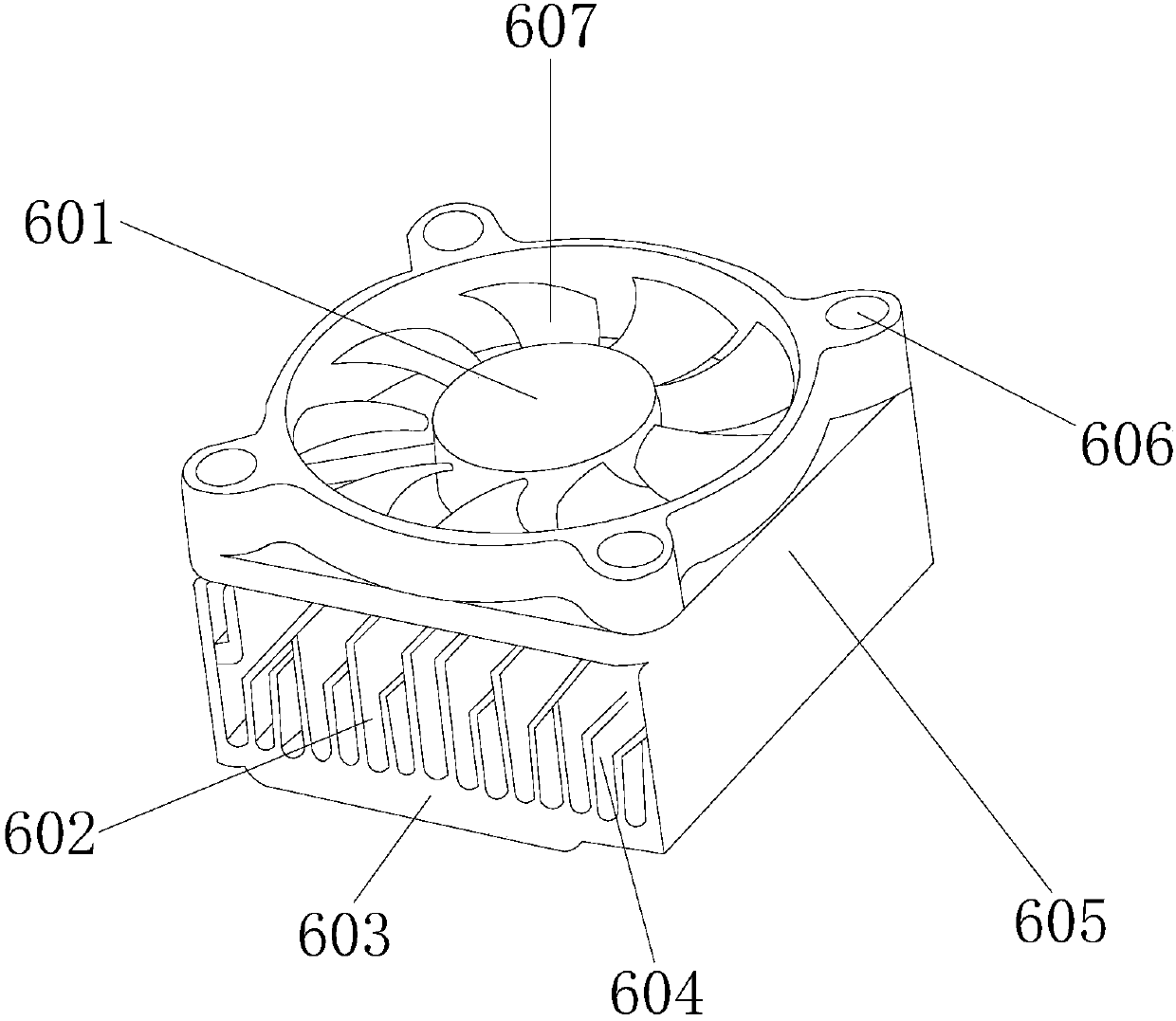

[0019] see Figure 1-Figure 3 , the present invention provides a technical solution: a folding and dividing machine for non-woven tablecloth, its structure includes an adjusting head 1, a working head 2, a working plate 3, a bracket 4, a backing plate 5, a fan heating device 6, and a partition 7 , support plate 8, motor box 9, the through hole provided with the outer ring on the right side of the adjustment head 1 and the left side surface of the motor box 9 is movably connected by interference fit, and is tightly fitted by a tight collar, and the working head 2. The upper outer ring runs through the bottom of the motor box 9, and is electrically connected to the connection provided inside the motor box 9. The edge of the bottom surface of the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com