Surface dust removing device for liquid crystal glass sheet before powder spraying

A technology for dust removal device and liquid crystal glass, which can be applied to devices for coating liquid on the surface, pretreatment of surfaces, cleaning of flexible objects, etc., can solve the problems of low efficiency, time-consuming and labor-intensive, affecting the good powder spraying of liquid crystal glass sheets, etc. To achieve the effect of simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

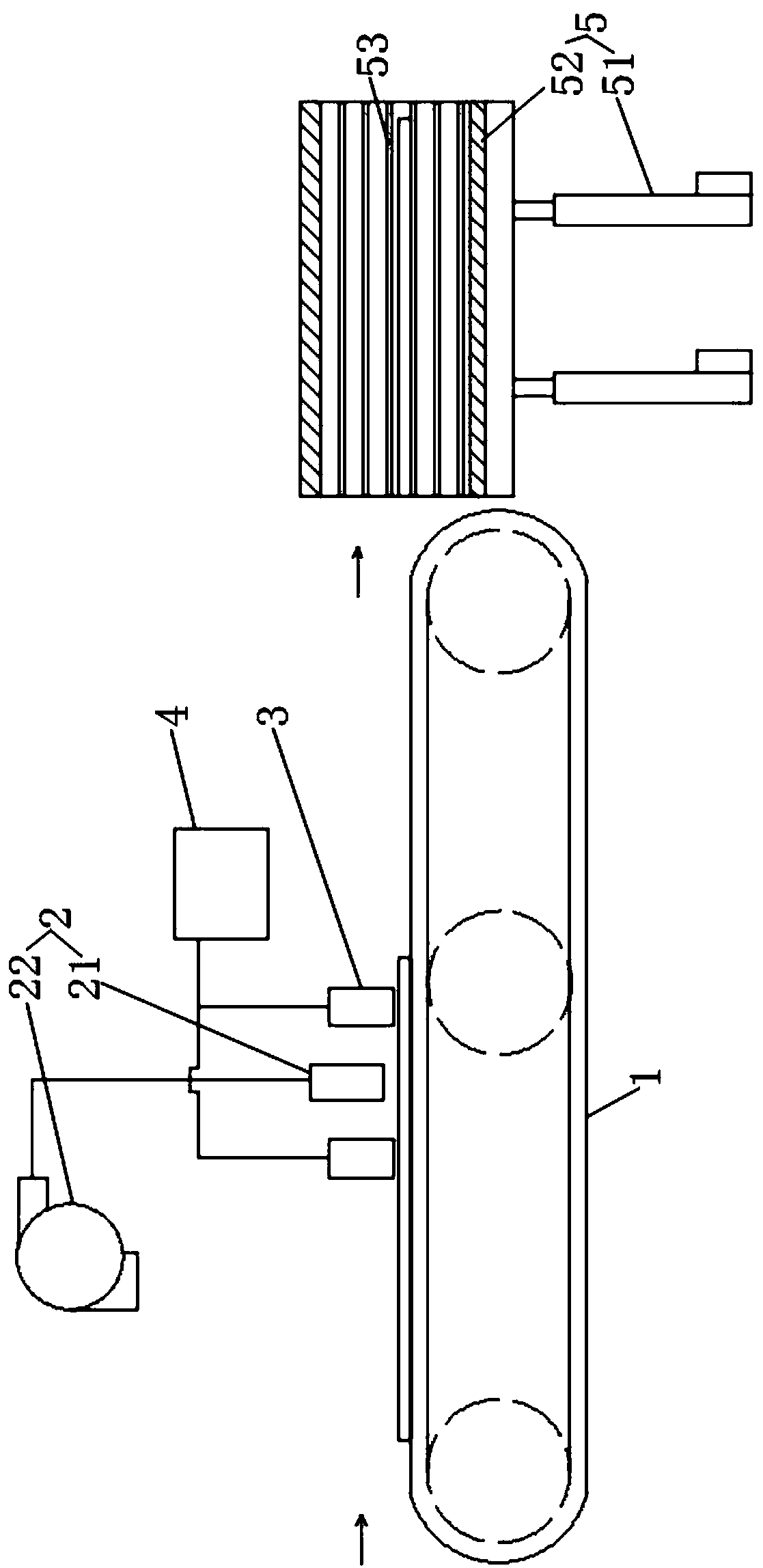

[0024] Example: such as figure 1 As shown, the dust removal device on the front surface of the liquid crystal glass sheet of the present embodiment includes a linear conveying device 1 and a blowing dust removal device 2;

[0025] One end of the linear conveying device 1 is a feed end, and the other end is a discharge end;

[0026] The above-mentioned blowing and dust removing device 2 is arranged above the conveying surface of the above-mentioned linear conveying device 1, in order to blow off the dust on the surface of the liquid crystal glass sheet passing through the conveying surface of the above-mentioned linear conveying device 1, and the air outlet direction of the above-mentioned blowing and dust removing device 2 faces the above-mentioned The feeding end of the linear conveying device 1 is inclined downward.

[0027] During the operation, the glass sheet is continuously released from the feed end of the linear conveying device 1, and the glass sheet is conveyed to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com