Swing spanner improved structure

A technology of swinging head and driving head, applied in the field of hand tool wrench, can solve the problems such as cracks in the meat wall, affecting the torque value of the wrench, damage and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

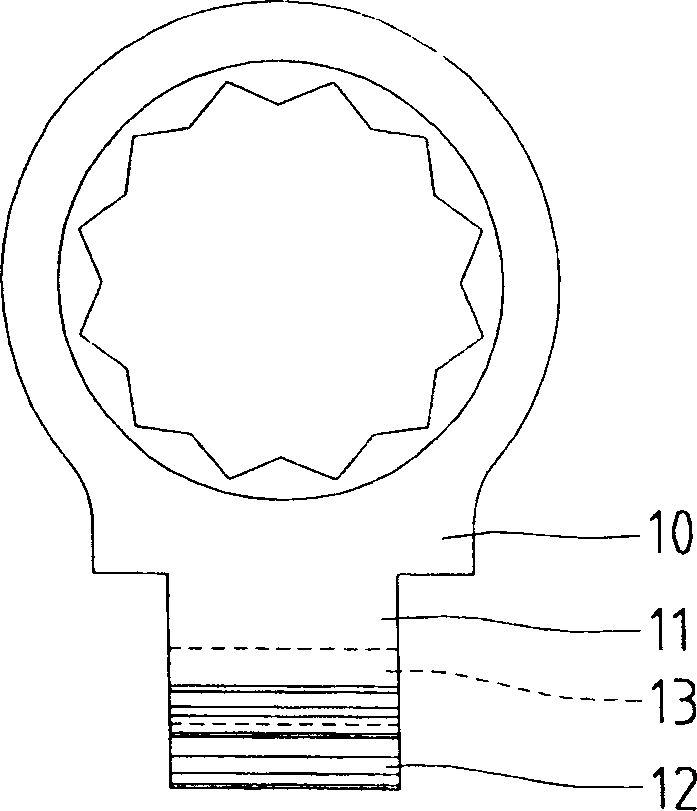

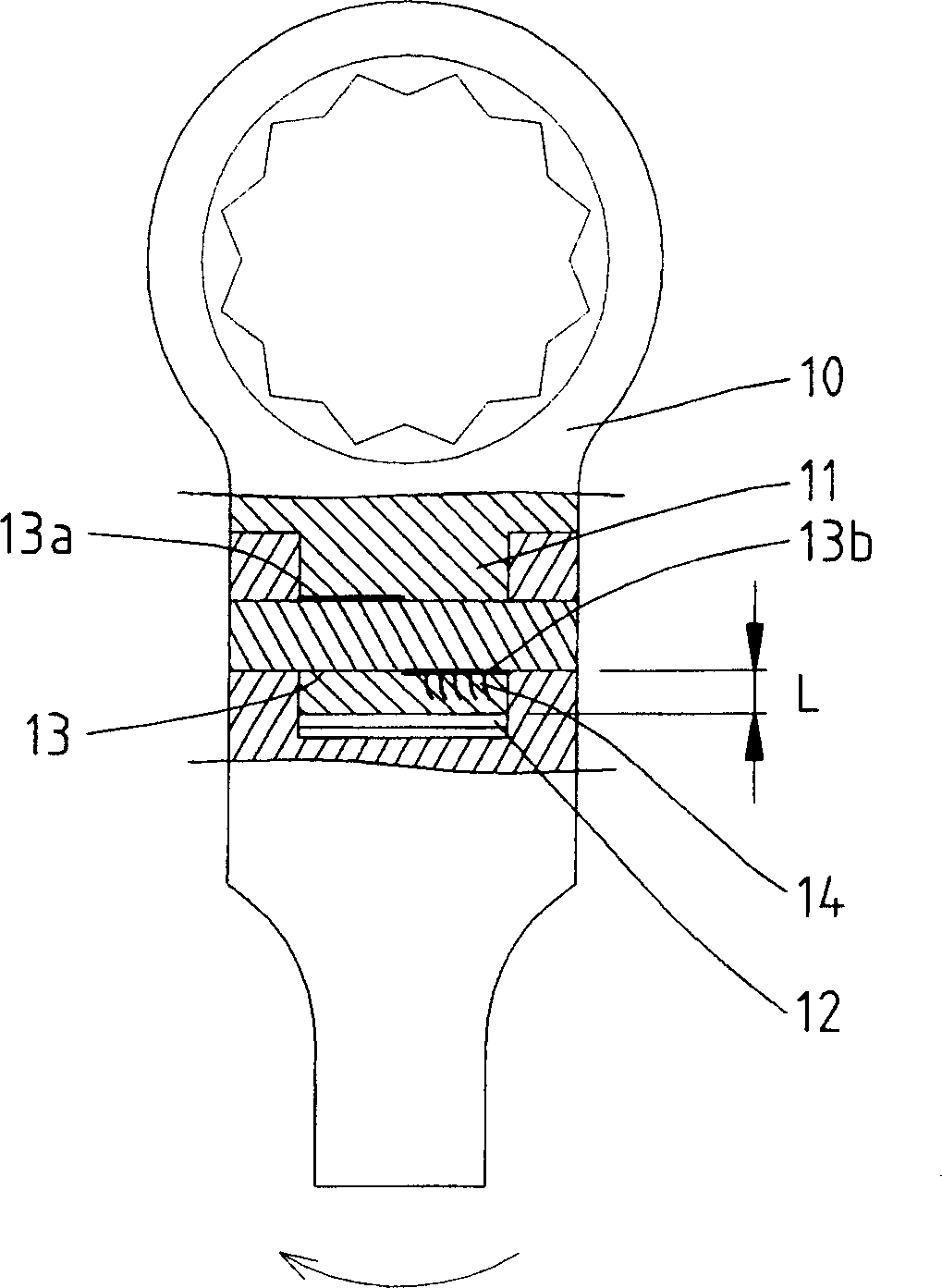

[0052] Referring to FIG. 7 , according to the first embodiment of the present invention, the swing head wrench 30 can be used to turn a screw.

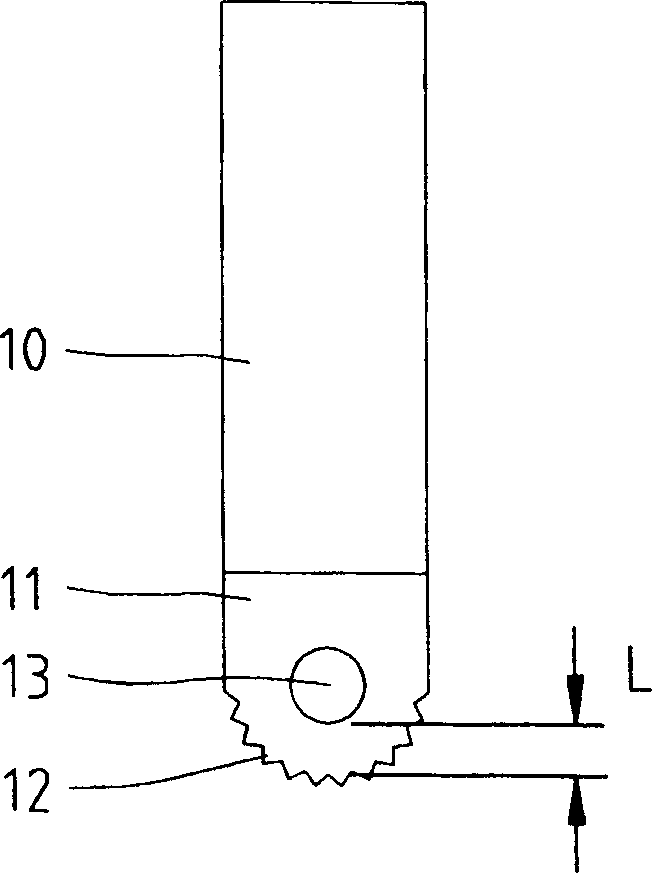

[0053] refer to Figure 8 , the swing head wrench 30 includes: a driving head 40, a handle 50 and a locking mechanism 60, one end of the driving head 40 is pivotally arranged on the handle 50, the locking mechanism 60 is located in the handle 50, and can be selected The relative pivotal relationship between the driving head 40 and the handle 50 is limited permanently.

[0054] The driving head 40 includes a first end and a second end, the first end can be used to drive the screw, the second end is provided with a pivot, and the outer edge of the pivot includes a first part and a second part, the The first part of the outer edge of the hub is provided with teeth, the arc surface of the second part of the hub is higher than the root of the tooth, and the position of the teeth of the first part is relatively located at the end of the wr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com