Multifunctional machine for processing rice-noodle and manufacture method

A multi-functional, rice noodle machine technology, applied in the field of rice noodle making equipment and rice noodle making by rice noodle making equipment, can solve problems such as large power consumption, burnt motor, inability to process, etc., achieve super toughness and gluten, and the overall structure is scientific , The effect of reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

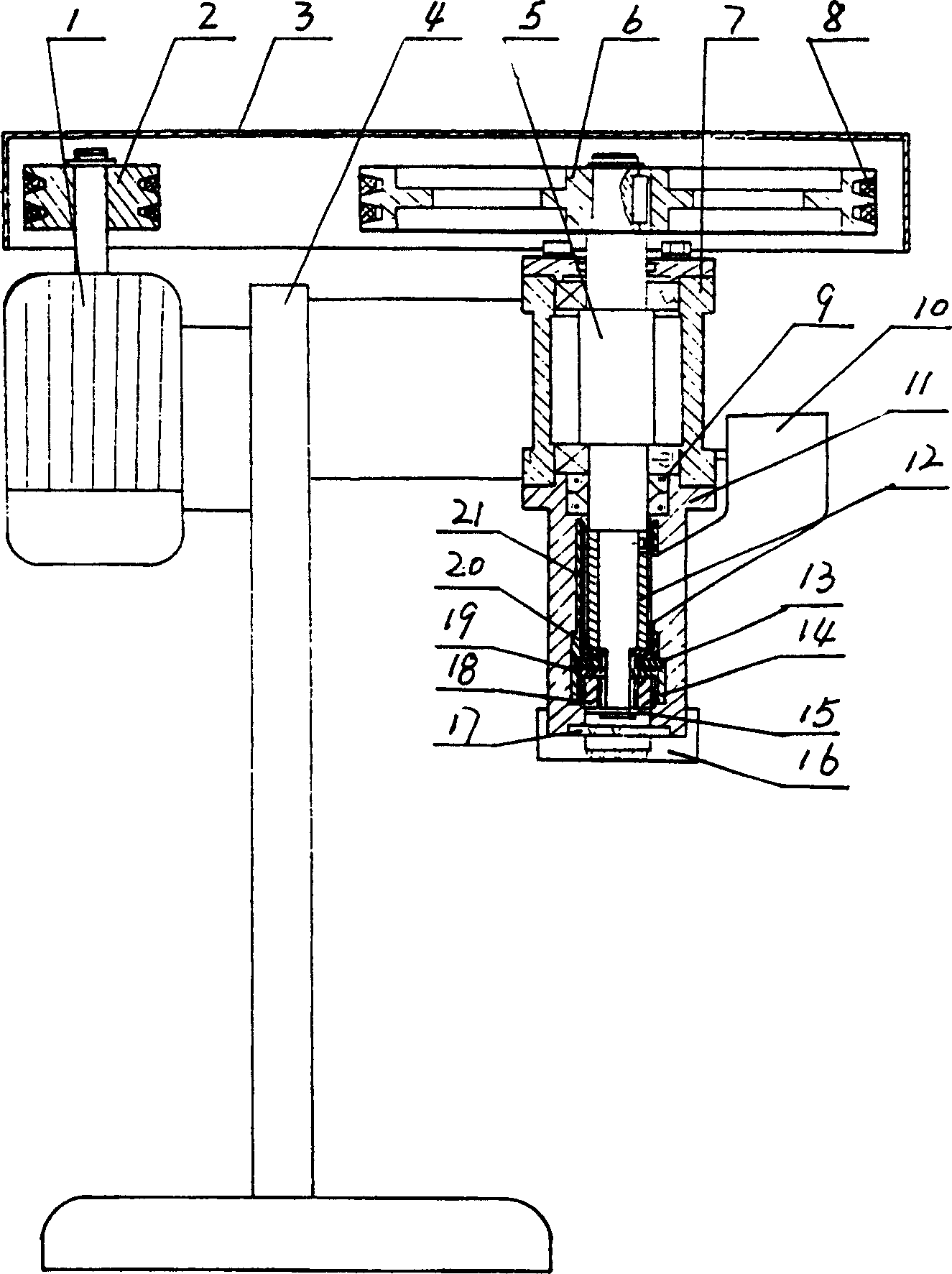

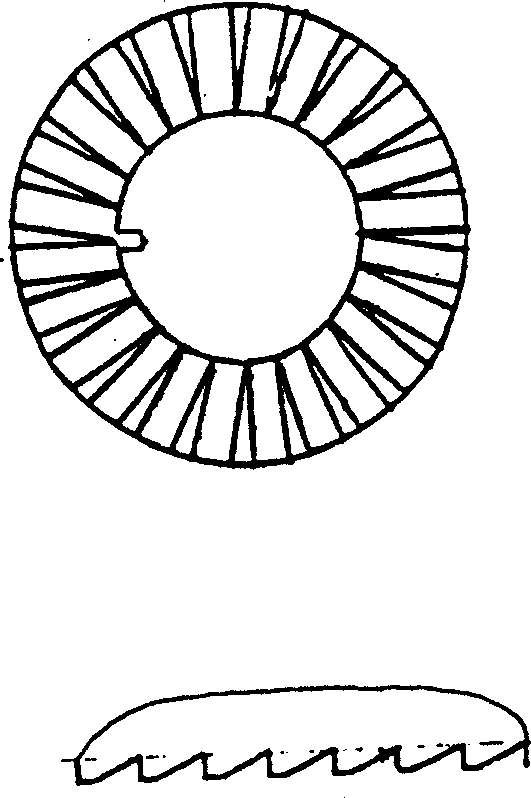

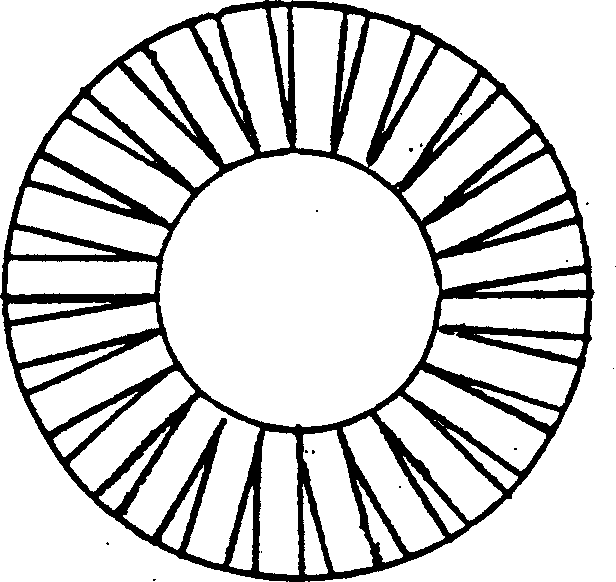

[0012] Embodiment 1: with reference to attached Figure 1~3 . Multi-functional rice noodle machine, vertical frame (can be -shaped structure, also can be frame structure) 4 is a motor 1 and the shaft is installed vertically upwards (the pulley 2 is installed on the shaft), and the other side is longitudinally distributed The rice noodle processing molding device, this device is driven main shaft 5 to rotate by power machine (as electric motor, diesel engine) by belt pulley 6, belt 8 by transmission mechanism. The transmission mechanism is covered with an organic cover 3. The main shaft 5 is a through shaft and is a stepped through shaft. In the rice noodle processing and forming device, the upper end of the main shaft 5 is a pulley 6 and is fixedly connected with the main shaft by a key. The main shaft below the pulley 6 is a bearing seat 7, and the main shaft 5 is installed on the bearing seat 7. The bearing seat 7 is connected to the body 11. An oil seal 9 is arranged on...

Embodiment 2

[0013] Embodiment 2: The production method of the multi-functional rice noodle machine, the material in the feeding hopper is soaked and under the action of gravity, directly enters the helical teeth in the variable-diameter spiral crushing sleeve through the feed port of the body, and the power machine drives the rice noodle processing and forming device The main shaft rotates, and the main shaft drives the variable-diameter spiral crushing sleeve to rotate. The material rotates in the cylindrical mill formed by the external teeth of the variable-diameter spiral crushing sleeve and the internal teeth of the variable-diameter coarse grinding sleeve to crush and coarsely grind the material. The coarsely ground material enters the The outer teeth of the grinding cylinder enter the middle mill consisting of the upper single-sided movable grinding disc and the double-sided fixed grinding disc for fine grinding. The mill composed of the lower single-sided fixed grinding disc is fine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com