A parallel metal three-dimensional printing method based on induction melting

A three-dimensional printing and induction melting technology, applied in the field of additive manufacturing, can solve the problems of inability to achieve parallel molding, stress accumulation, slow molding speed, etc., to eliminate the problem of molding thermal stress, eliminate residual stress accumulation, and reduce surface roughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in combination with specific embodiments.

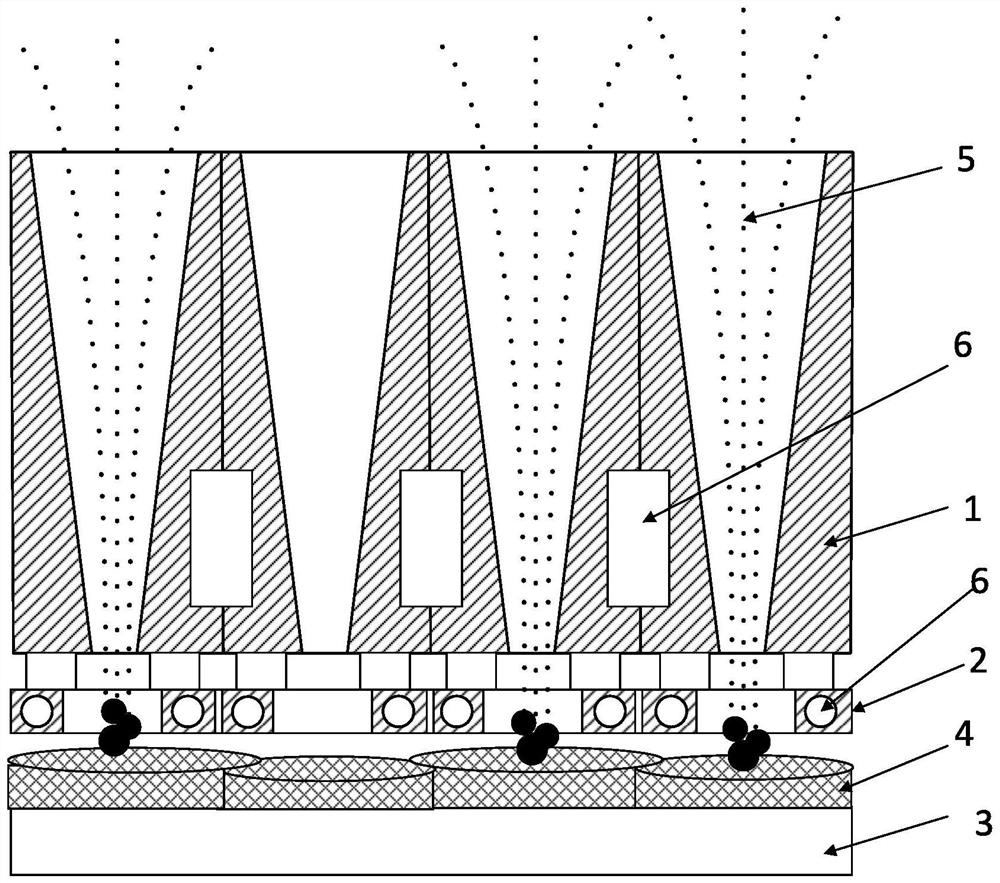

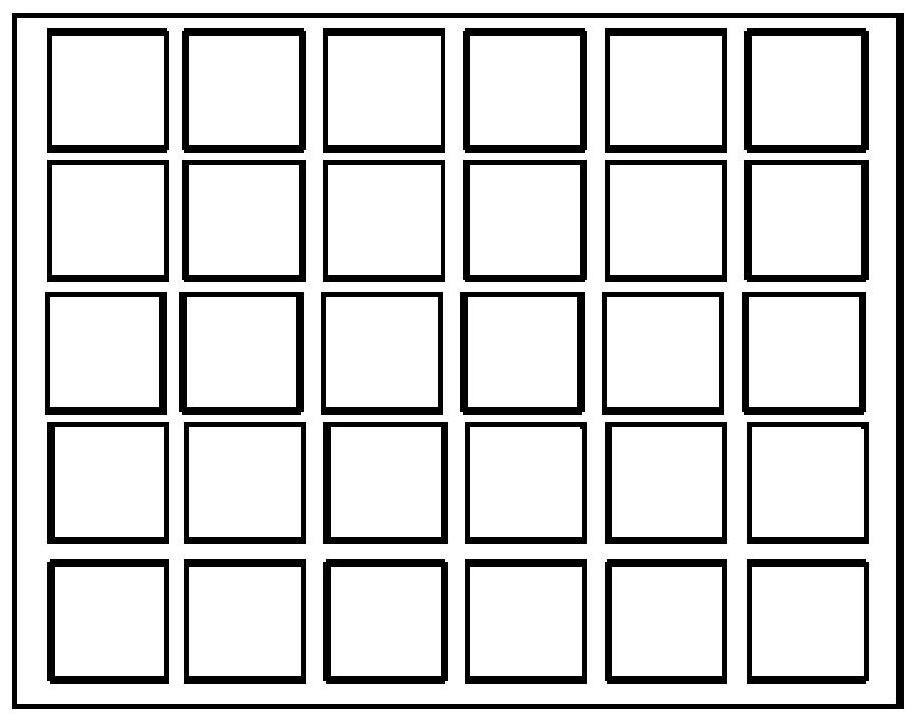

[0034] Such as figure 1 As shown, the present invention provides a parallel metal powder induction smelting forming array plate, including a parallel nozzle array composed of several powder feeding nozzles 1 and an induction coil 2, and the induction coil 2 is a high-frequency induction coil or an intermediate frequency induction coil. The induction coil, the induction coil 2 can be one or more; if it is one, it is arranged at the exit end of the parallel nozzle array, and the inner ring of the coil is required to include the parallel nozzle array, that is, the induction coil 2 can The metal powder sprayed by any nozzle of the parallel nozzle array produces an induction melting effect; if there are more than one, the number is required to be equal to the number of powder feeding nozzles 1, and each induction coil 2 is fixedly arranged on each The outlet end of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com