A Partitioned Parallel 3D Printing Forming Method for Large Precision Metal Parts

A technology of three-dimensional printing and metal parts, which is applied in the field of additive manufacturing, can solve the problems of inability to realize parallel molding, stress accumulation, slow molding speed, etc., and achieve the elimination of molding thermal stress problems, elimination of residual stress accumulation, and reduction of surface roughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in combination with specific embodiments.

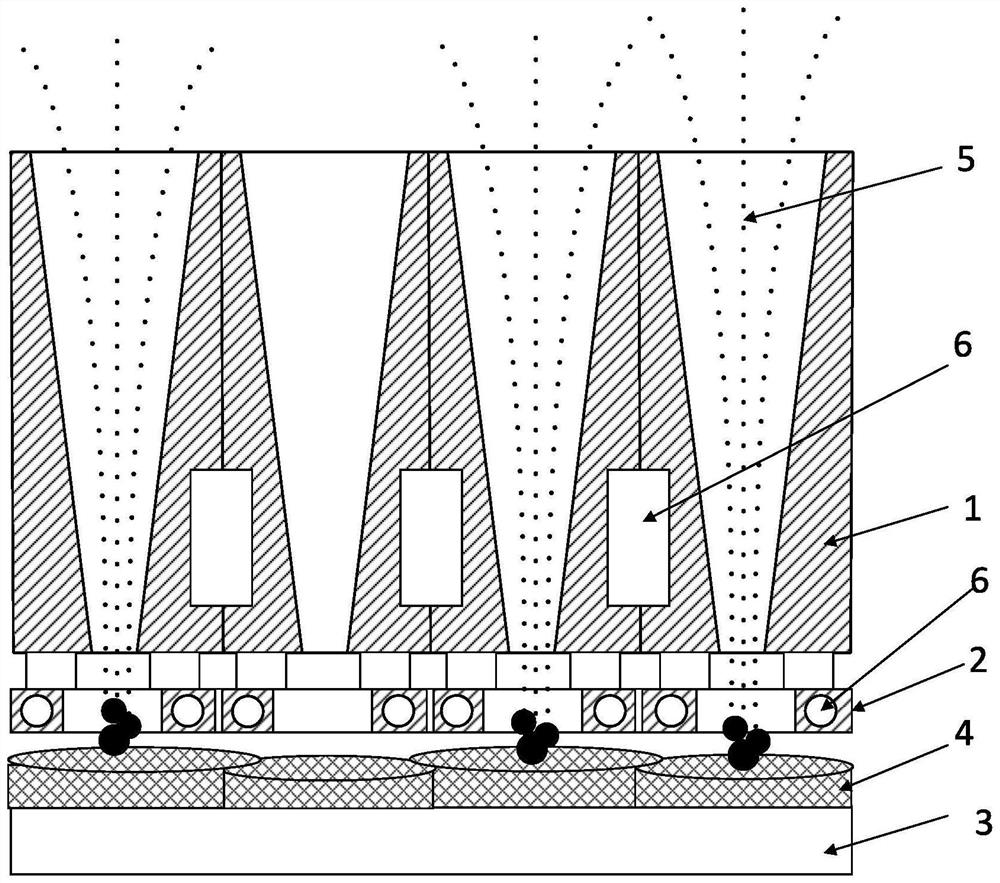

[0037] Such as figure 1 As shown, the present invention provides a metal powder induction smelting forming array plate, which includes a parallel nozzle array composed of several powder feeding nozzles 1 and an induction coil 2, and the induction coil 2 is a high-frequency induction coil or an intermediate-frequency induction coil , there are multiple induction coils 2, and the number of them is required to be equal to the number of powder feeding nozzles 1. Each induction coil 2 is fixedly arranged at the exit end of each powder feeding nozzle 1 in one-to-one correspondence, so that the number of induction coils 2 The center of the magnetic field is located on the central axis of the exit end of the powder feeding nozzle 1 .

[0038] A cooling water circulation channel 6 is provided inside the outer wall of the powder feeding nozzle 1 and inside the induction co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com