Electromagnetic contactor

A technology of electromagnetic contactor and electromagnetic coil, which is applied in the direction of electromagnetic relay, relay, detailed information of electromagnetic relay, etc., can solve the problem of increasing the size of electromagnetic contactor, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

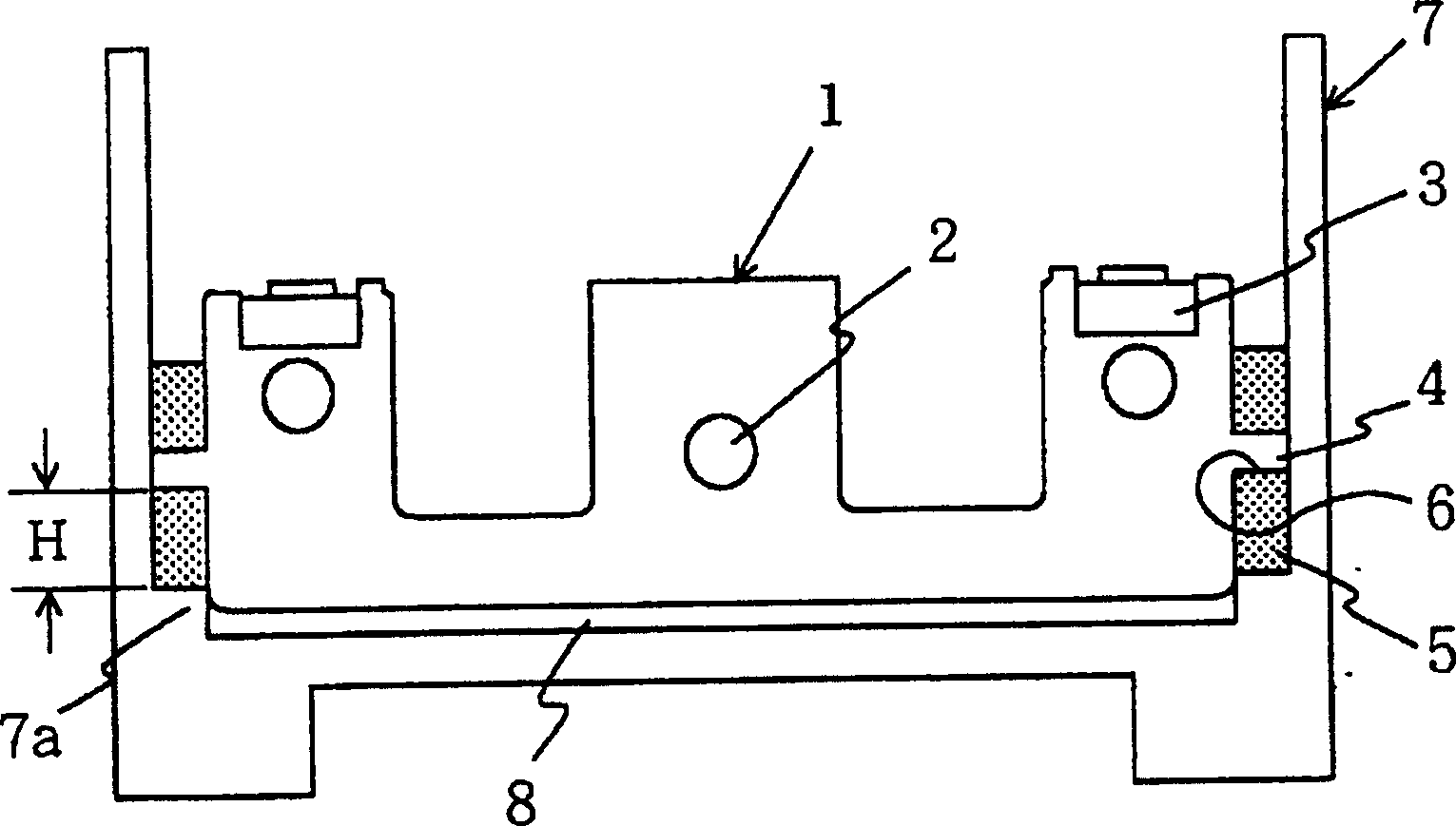

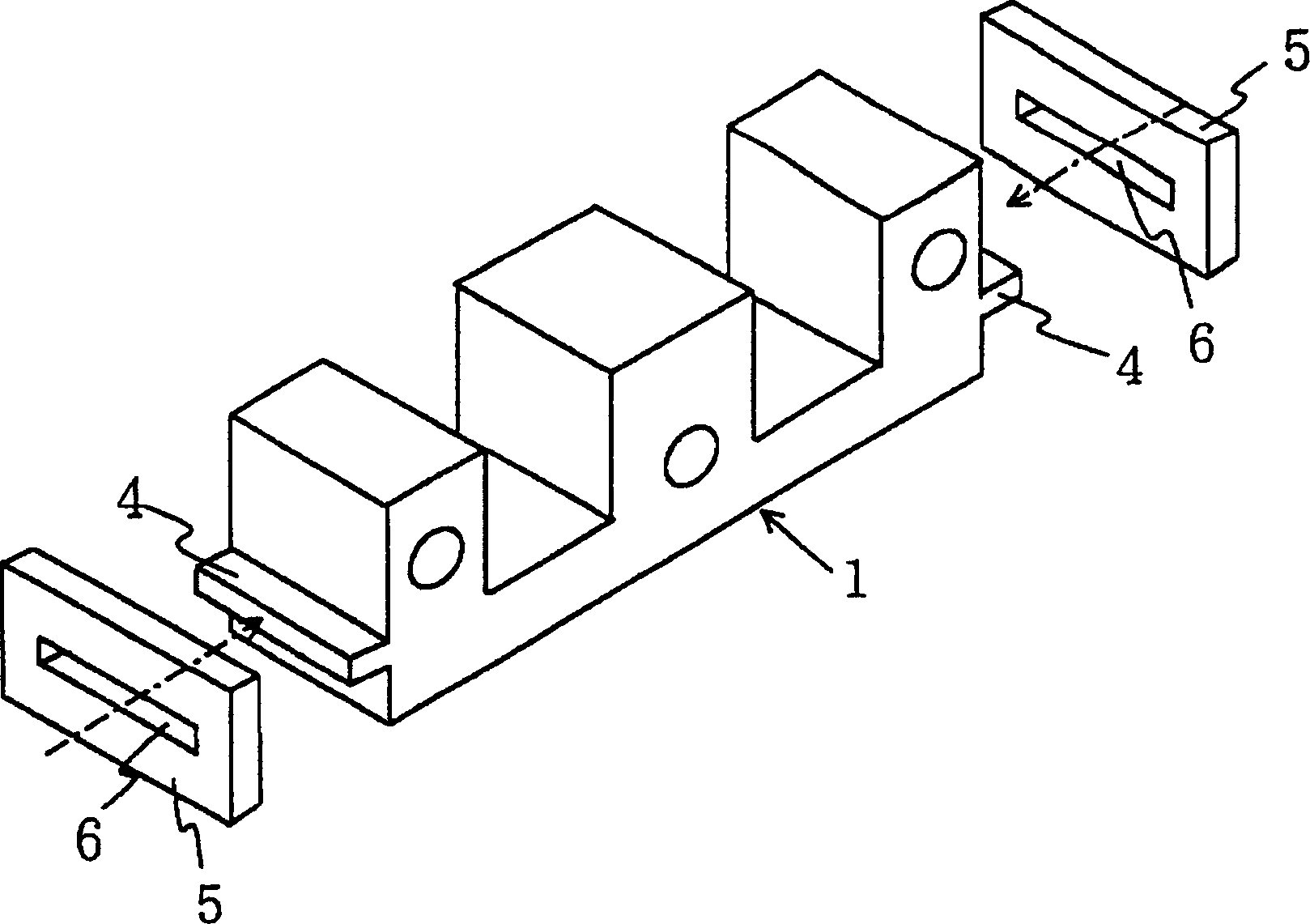

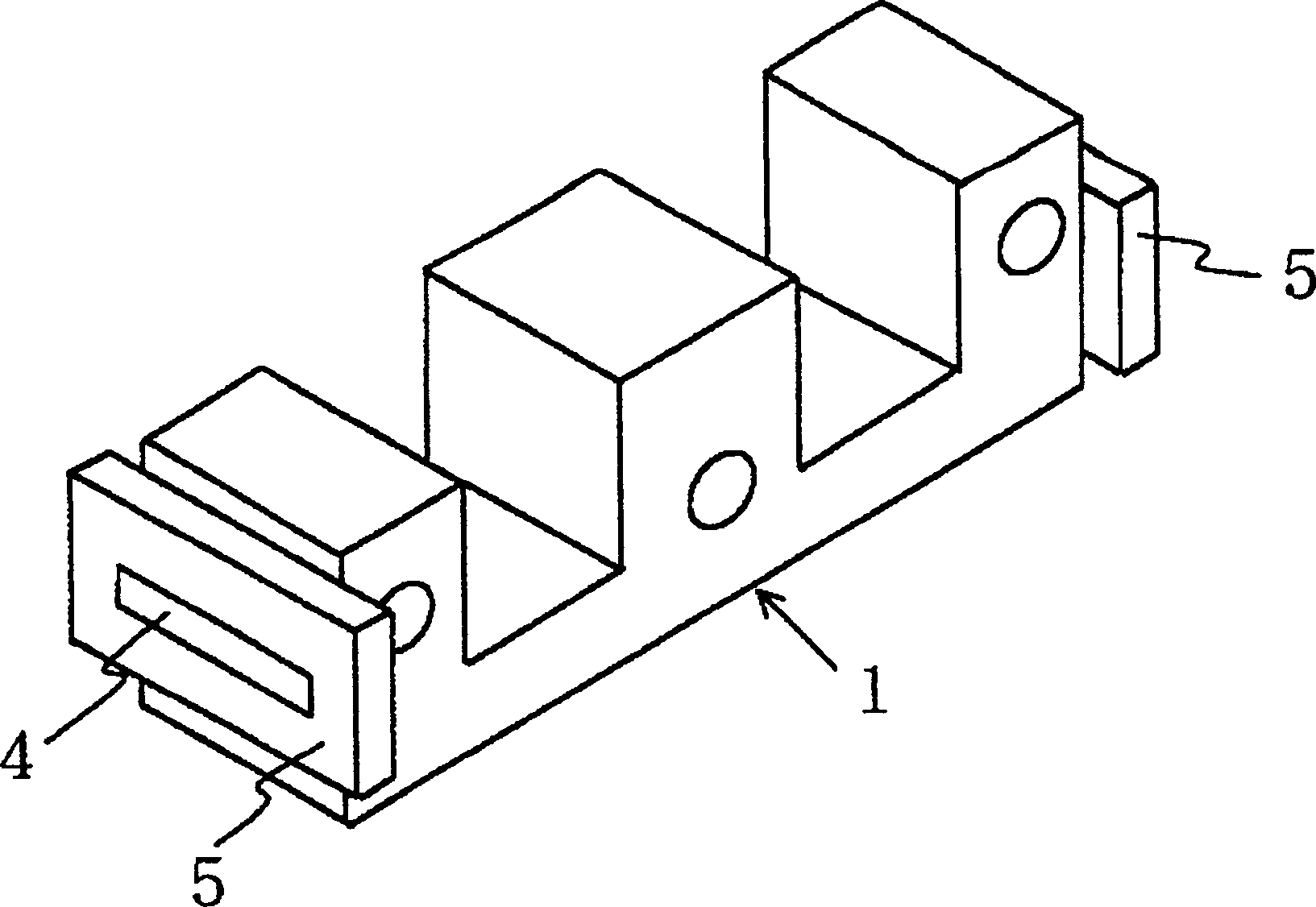

Figure 1-3 A basic embodiment of the invention is shown in which figure 1 It is a cross-sectional view showing the fixed iron core installed in the bottom box of the AC electromagnetic contactor, figure 2 is an exploded perspective view showing the figure 1 The fixed core and buffer material in the image 3 is a perspective view showing the combination of the fixed core and the cushioning material. exist Figure 1-3 Among them, the fixed iron core 1 is E-shaped, and as it is known, it is made of many silicon steel sheets punched into the shape shown and fastened to each other with rivets 2 and the shielding coil 3 ( figure 1 ) are attached to the respective magnetic poles of the left and right legs. In this embodiment, the rectangular boss 4 is integrally formed with the left and right end surfaces of the fixed core 1 and punched out at the same time.

[0019]

On the other hand, reference numeral 5 refers to a rectangular plate-like cushioning material which is int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com