Buffer training bullet

A technology for buffering springs and bullets, applied in the field of military training bullets, can solve the problems of short service life and easily damaged guns, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

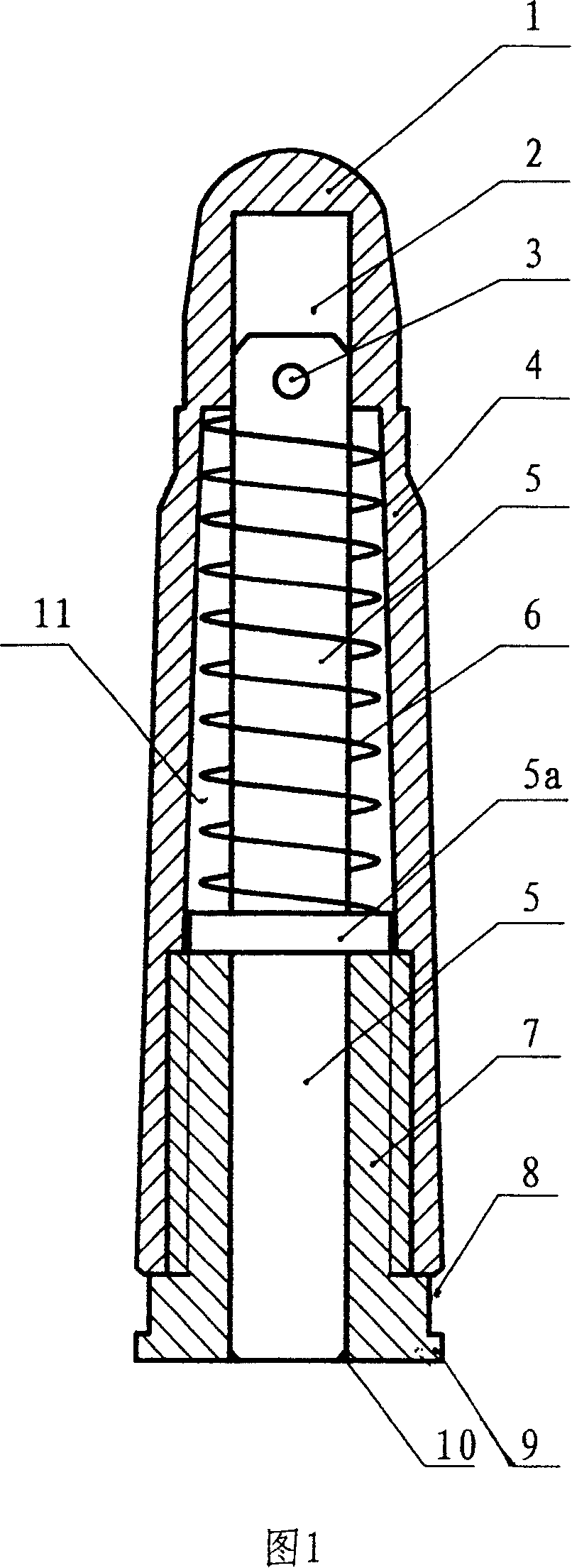

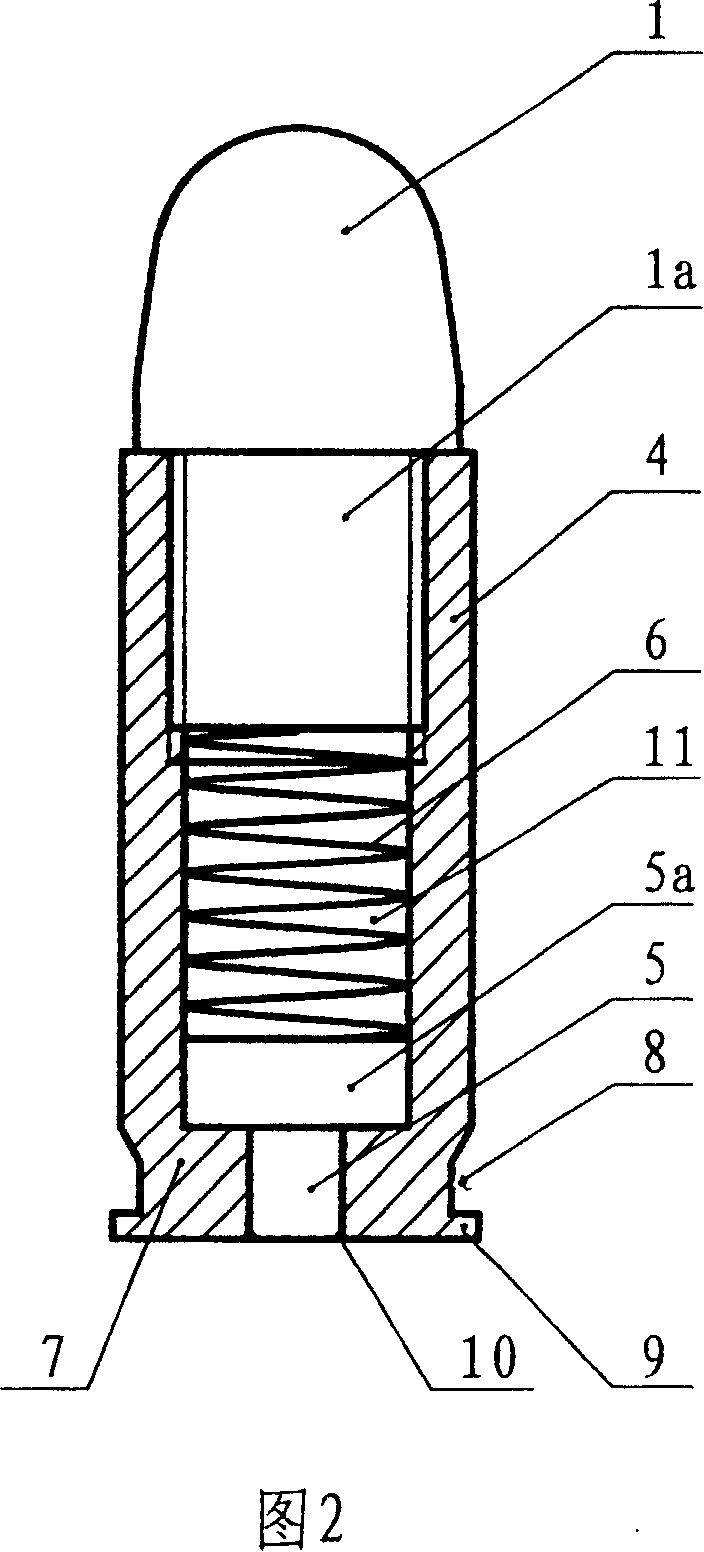

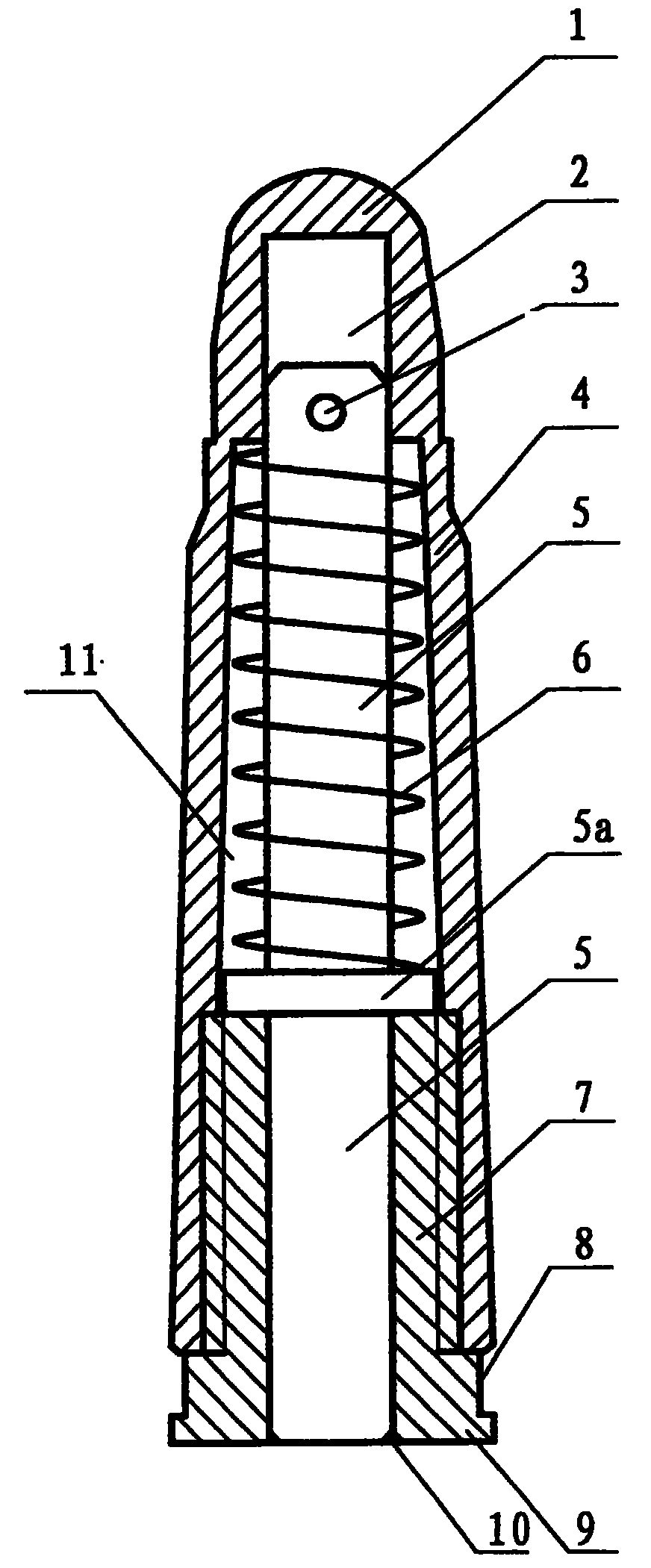

[0009] In the buffer training bullet of the present invention, the bullet 1 is connected with the bullet body 4, the bullet body 4 has an inner hole 11, and the bottom part of the inner hole 11 wall is provided with threads, and the bullet rear seat 7 of the through hole 10 is connected with the inside of the bullet body 4 by its thread. The lower part of the hole 11 is threadedly connected, and the cavity 2 arranged in the warhead 1 communicates with the inner hole 11 correspondingly; the buffer shaft 5 is respectively installed in the inner hole 11 and the through hole 10, and the middle part of the buffer shaft 5 is provided with a boss 5a. The platform 5a is in contact with the bullet rear seat 7; the buffer spring 6 is sleeved on the buffer shaft 5, and its top is in contact with the edge of the lower end of the bullet 1, and its bottom is in contact with the boss 5a. The bullet rear seat 7 is connected with the bullet body 4, and the inner hole 11 wall top of the bullet b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com