Method and device for in-site measuring gas hydrate and deposit sediment heat stability containing hydrate

A gas hydrate and hydrate-containing technology, which is applied in the direction of measuring devices, material thermal development, material thermal analysis, etc., can solve the quality problem of hydrate formation, can not give the thermal conductivity change with temperature, and is not suitable for measuring the thermal conductivity of hydrate Coefficient and other issues, to achieve the effect of wide temperature and pressure range, compact test structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

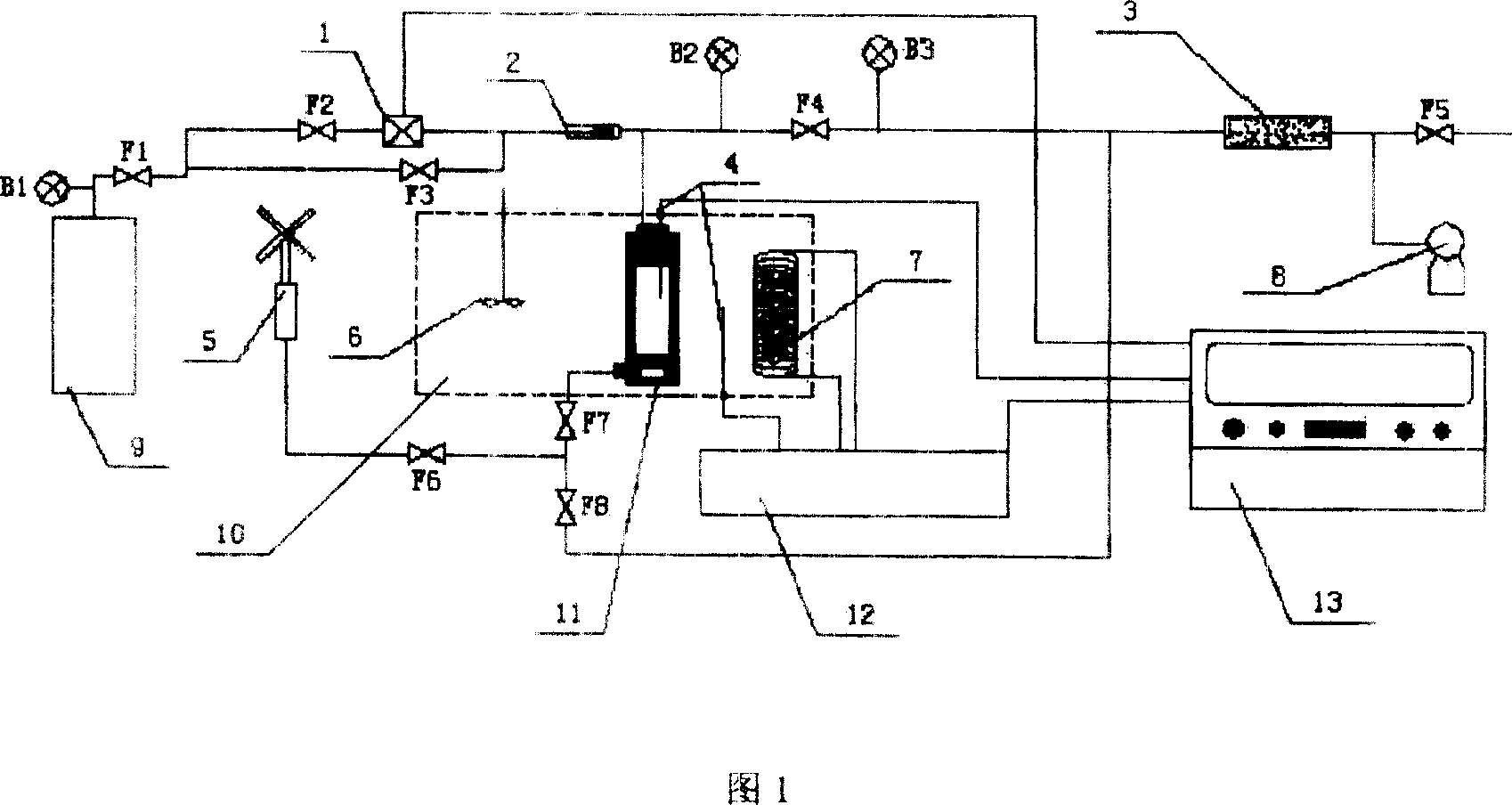

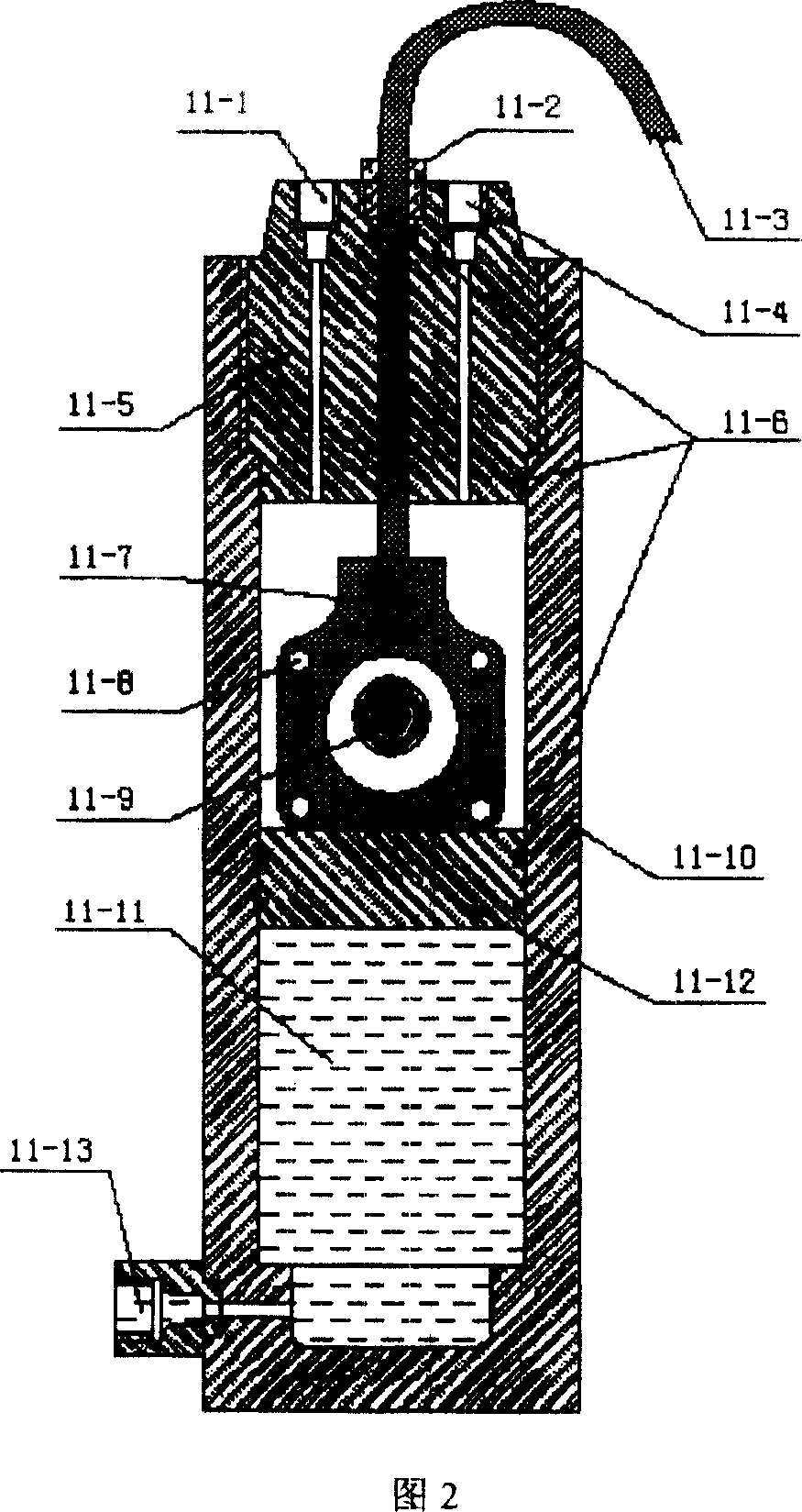

[0036] In Figures 1 and 2, methane gas and 280 ppm sodium dodecylsulfonate (SDS) aqueous solution are used as reactants to react and synthesize methane hydrate. Before the experiment, adjust the temperature control system earlier, the temperature of the reaction is set as 0 ℃, then clean the reactor 11 with the SDS aqueous solution of 280ppm that has been prepared, then inject 100 grams of sodium dodecylsulfonate (SDS) aqueous solution, and then The reactor lid 11-5 is put on and sealed. Then open the valves F1, F2, F3, F4 and F5, open and close the valve F1 continuously and quickly, let the methane gas in the gas cylinder 9 continuously flush the pipeline to discharge a part of the air, then close the valves F1 and F5, turn on the vacuum pump 8 to start pumping vacuum. After the vacuum gauge is stable, close the valve F4, open the valve F5 to reset the vacuum pump 8. Close the valve F2, open the valve F1 to start air intake, and wait for the system pressure to balance, clos...

Embodiment 2

[0039] The effective thermal conductivity of porous media containing tetrahydrofuran sand is measured by mixing sand and tetrahydrofuran solution. This example is to simulate the effective thermal conductivity measurement of actual sampling samples. As mentioned above, the temperature control system was set to 0°C before the experiment, and then 21% tetrahydrofuran aqueous solution was injected into the reactor, and the construction sand of 300-125 μm that passed the screening was slowly introduced into the solution with a glass rod until the sand layer completely submerges the Hotdisk probe. Use a straw to suck out the excess tetrahydrofuran aqueous solution above the sand layer, place the entire reactor in a temperature control system, and start the reaction. After about 5-10 hours, the liquid phase is completely transformed into tetrahydrofuran hydrate, and it is aged under the current temperature and pressure conditions by keeping it warm for 2-3 days. Subsequently, in-si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com