Fluid valve device

A technology for fluid valves and shells, applied in valve devices, valve operation/release devices, valve details, etc., can solve problems that affect work efficiency and production costs, still fall, non-assembly and disassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described below with reference to the drawings.

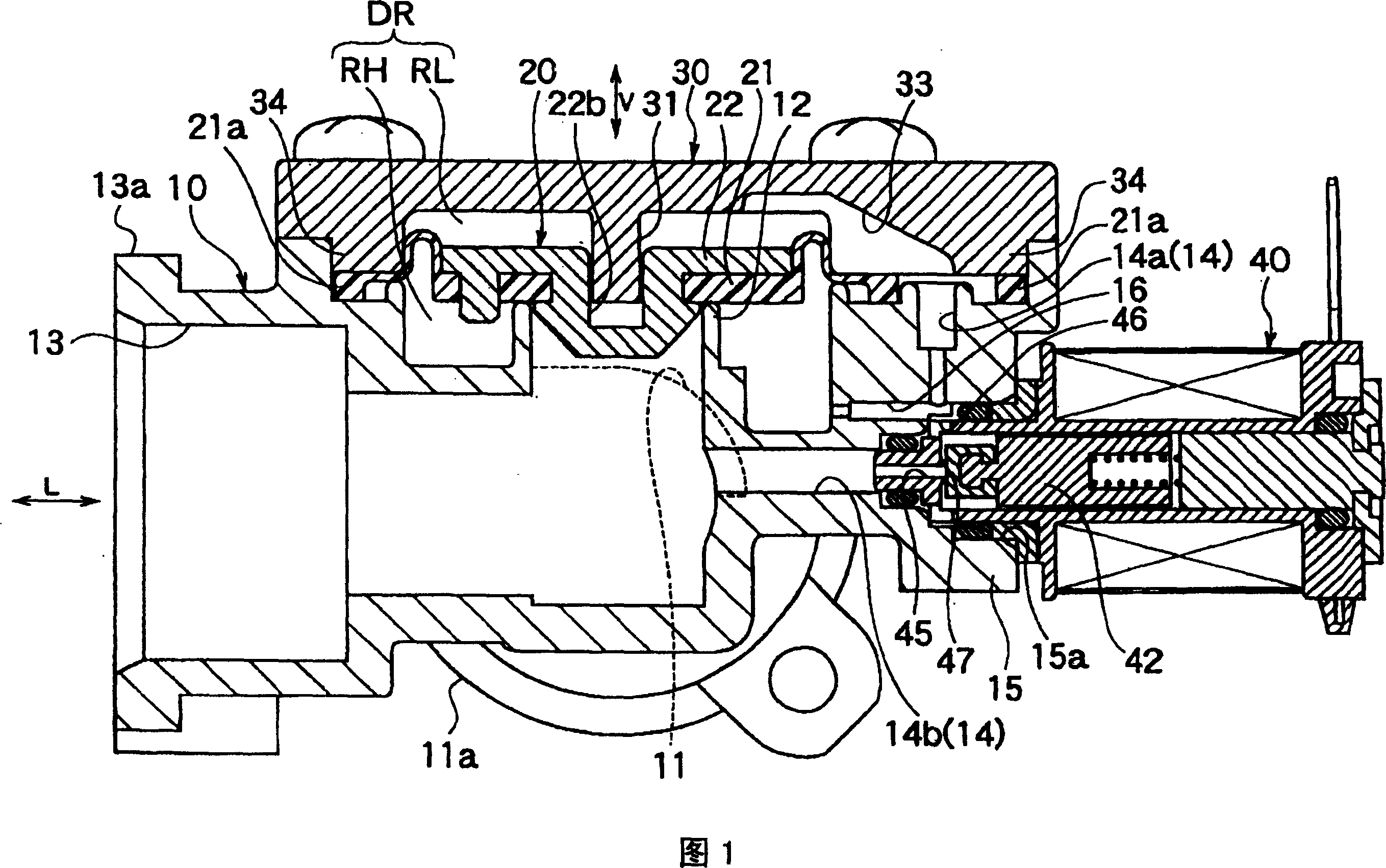

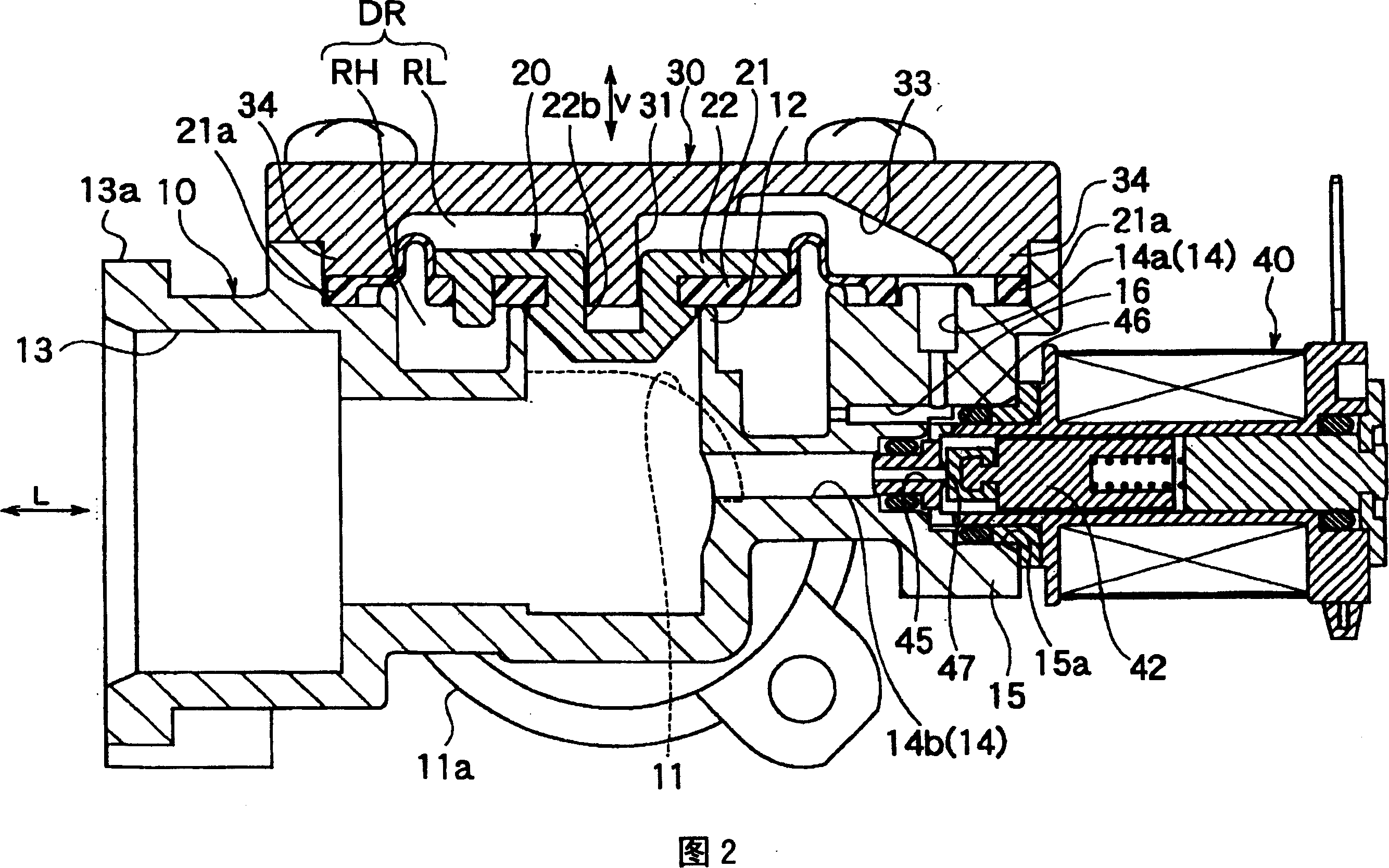

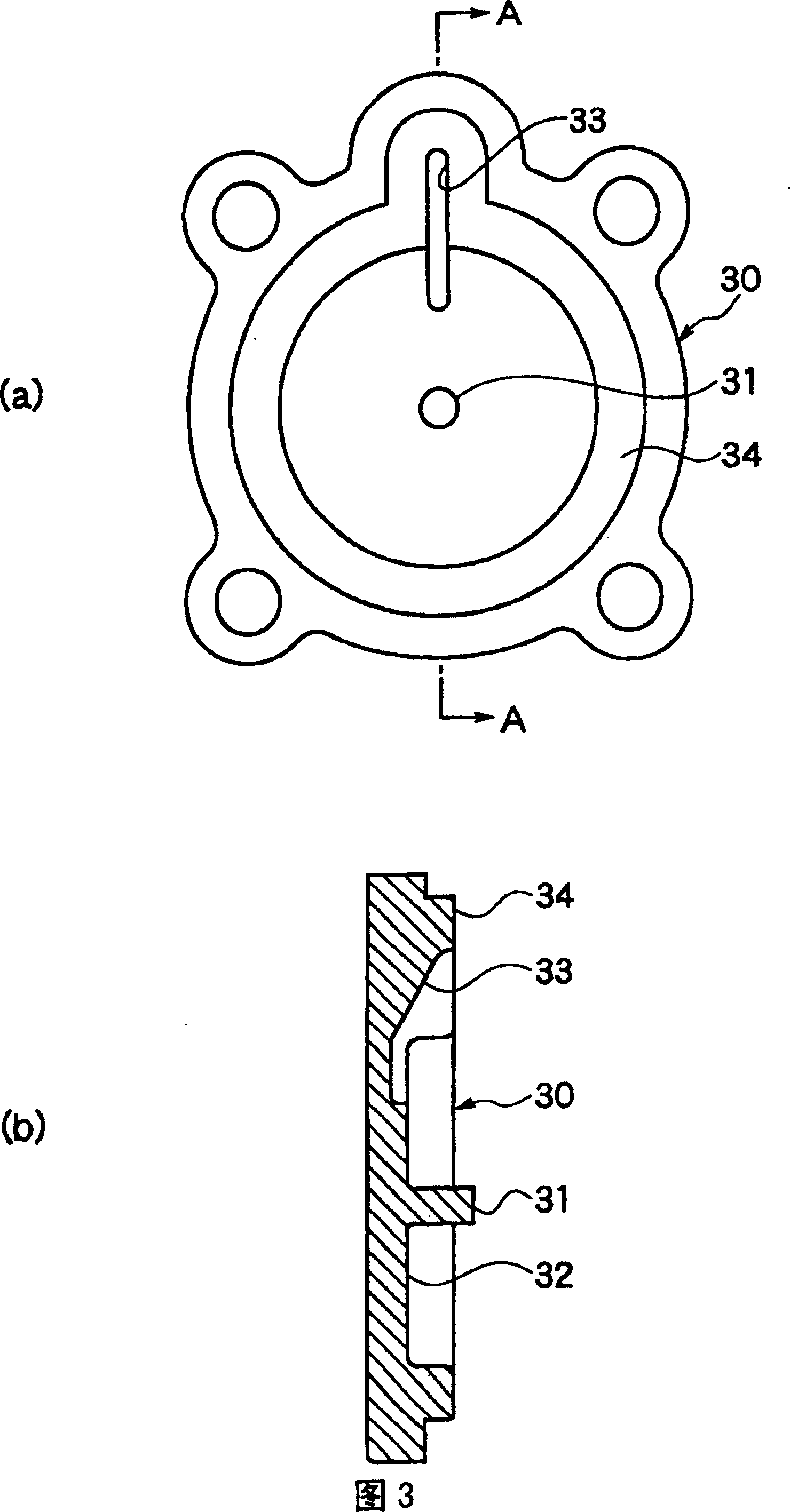

[0033] 1 and 4 show an embodiment of the fluid valve of the present invention. This fluid valve has the channel housing 10 of the inflow channel and the outflow channel of dividing fluid (being water here), the diaphragm valve 20 installed in the channel housing 10, is connected with the channel housing 10 of division diaphragm valve 20 back pressure chambers The valve cover 30 and the hydraulic control solenoid valve 40 connected with the channel housing 10 .

[0034] As shown in FIG. 1 and FIG. 2 , the channel housing 10 is composed of an inflow channel 11 extending rearward in FIG. The outflow passage 13 of the back pressure chamber RL and the outflow passage 13 are connected with the hydraulic control passage 14 and the flange 15 for installing the hydraulic control solenoid valve 40 is formed. Flange portions 11 a , 13 a connected to pipes are formed at opening ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com