Tester and testing method, and testing unit

A detection device and a detection component technology, which can be applied to measurement devices, devices that automatically compare measured values with reference values, and measurement electronics, etc., and can solve the problems of increasing surface mounting density and limited application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

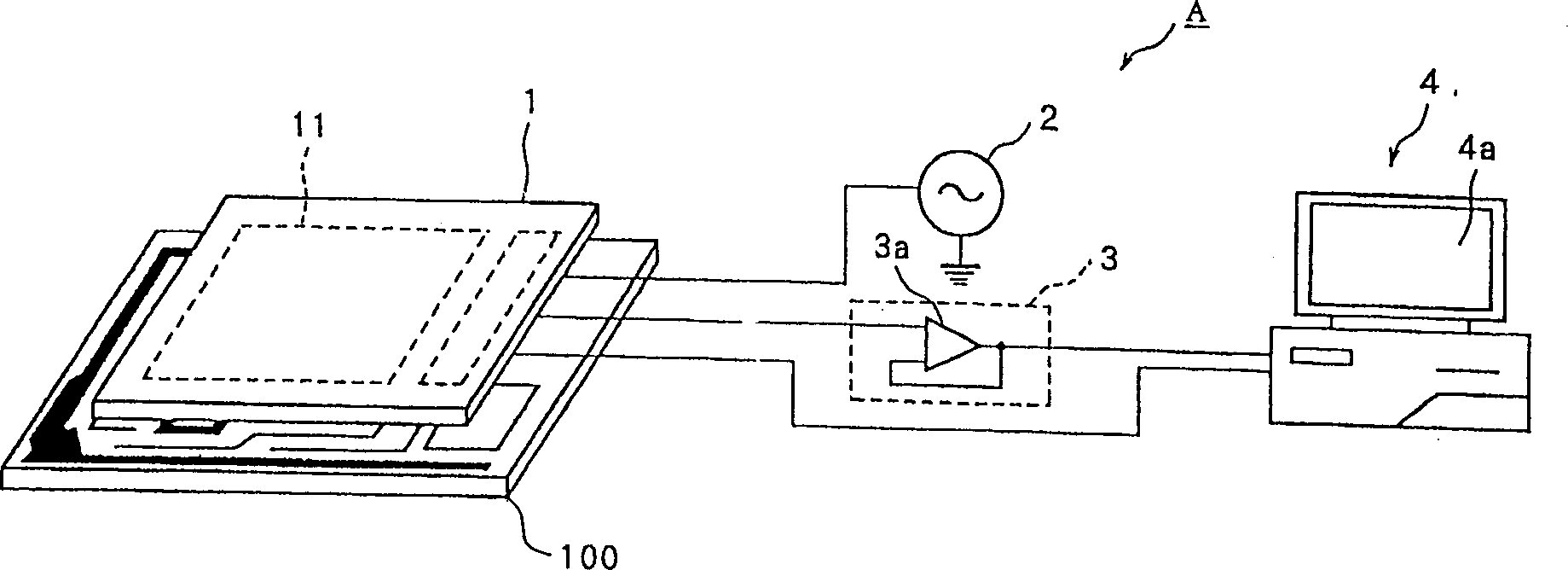

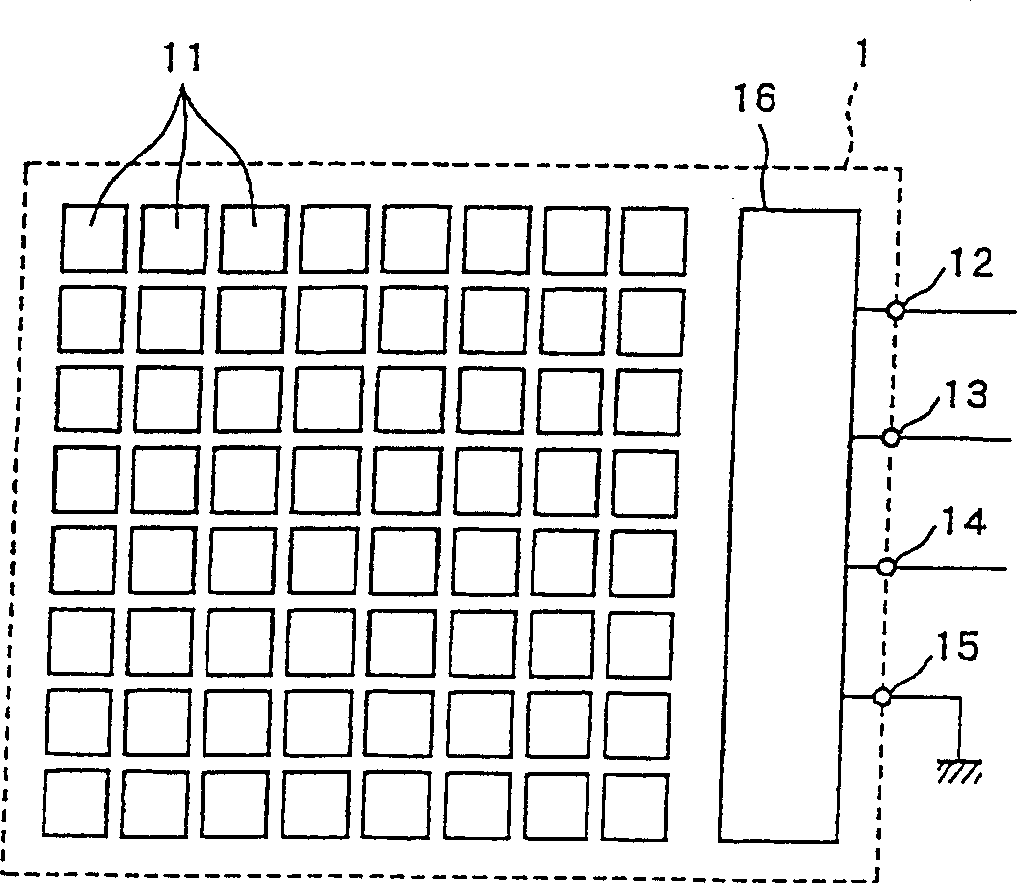

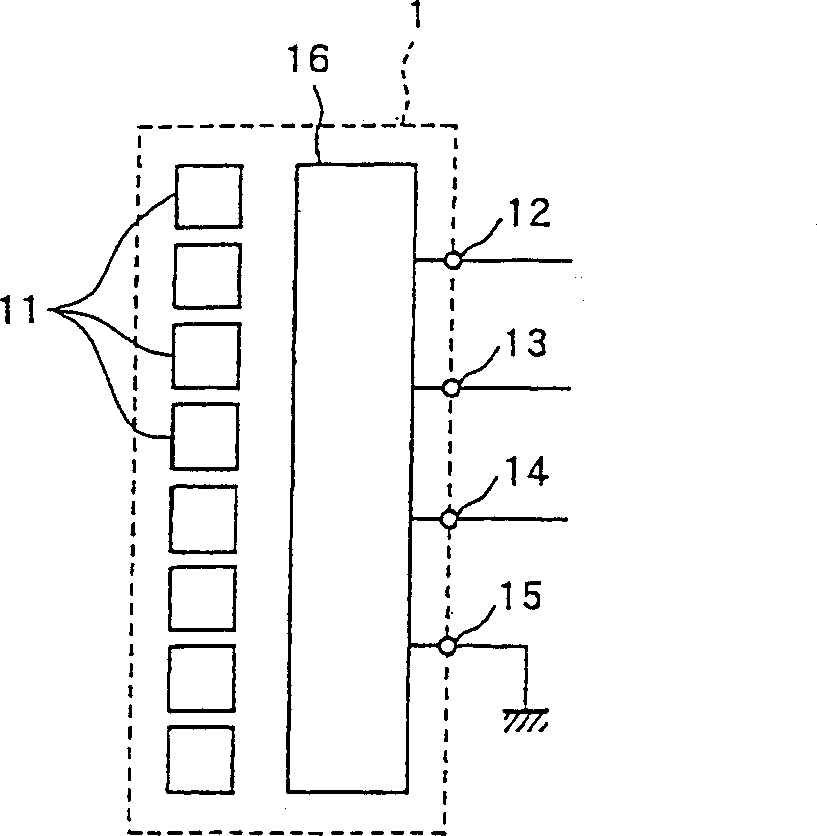

[0035] figure 1 It is a schematic diagram showing the configuration of a detection device A for detecting a conductive pattern on a circuit board 100 as a first embodiment of the present invention, figure 2 It is a schematic diagram showing the structure of the detection component 1 therein.

[0036]

[0037] The detection device A has a detection component 1, a signal source 2 for supplying a detection signal to the detection component 1, a processing circuit 3 for processing an output signal given by the detection component 1, and a control for the detection component 1, and can be based on The computer 4 is used to determine whether the conductive pattern on the circuit board 100 is disconnected, short-circuited, etc. by the output signal given by the processing circuit 3 .

[0038] The detection assembly 1 has several units 11 which are isolated from each other, the input terminal 12 which inputs the detection signal given by the signal source 2, the output terminal 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com