Dome shaped contact plate having good knocking sense and thin sheet installed with contact plate

A contact and sheet technology, applied in the direction of quick-action devices, emergency protection devices, electrical components, etc., can solve the problems of poor knock feeling, small movement, and inability to recover by itself.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

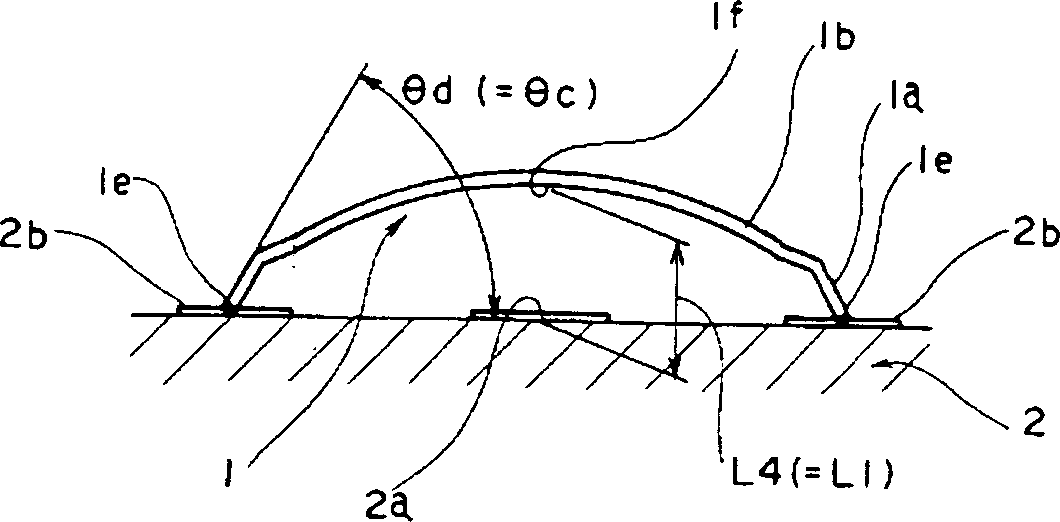

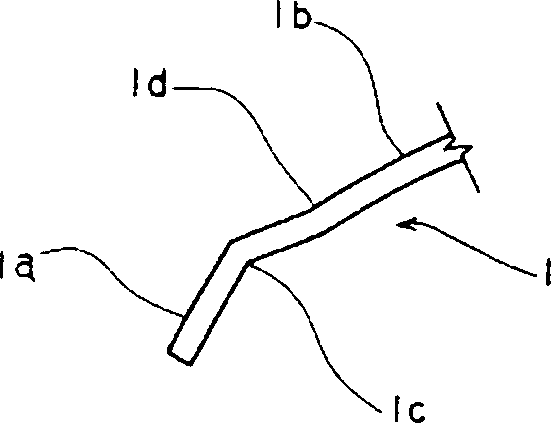

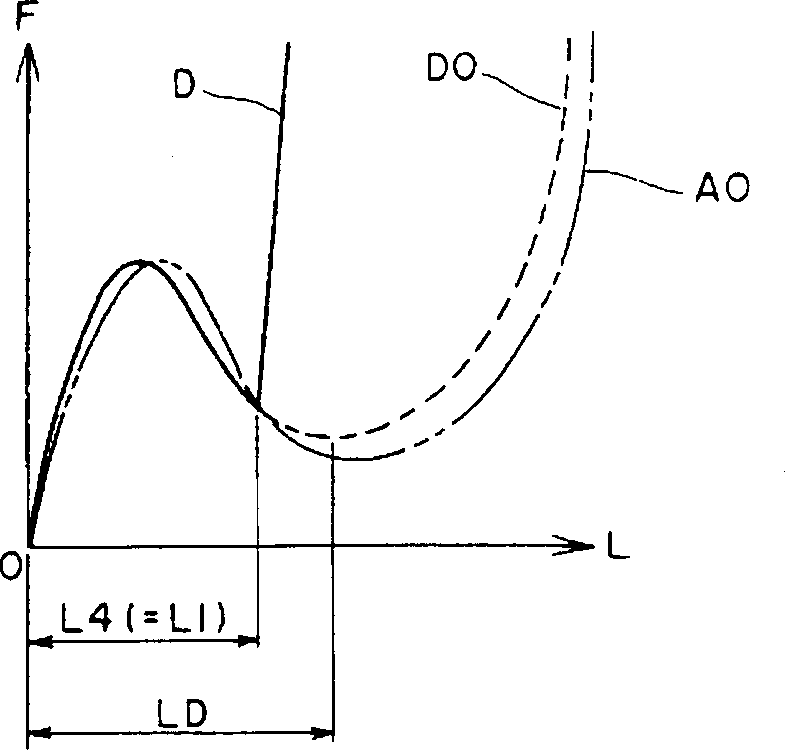

[0030] Below, an embodiment of the present invention is shown in Figure 1 to Figure 3 . figure 1 It is a sectional view showing the relationship between the movable contact and the fixed contact, figure 2 It is a partial sectional view showing the connection part of a side edge part and a dome part, image 3 It is an explanatory diagram showing the relationship between the operating force and the movement amount of the movable contact.

[0031] In the figure, the movable contact 1 is formed in a disc shape from a thin metal plate. The movable contact 1 is formed by a side edge portion 1a rising upward at a predetermined angle from the outer circumference of the disk portion toward the center of the disk portion, and a reversible dome portion 1b connected to the side edge portion 1a. The middle of the side edge portion 1a and the dome portion 1b are connected in a plurality of steps via a plurality of bending portions 1c, 1d (two in this embodiment).

[0032] The circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com