Tyre building drum

A tire and matching technology, applied in the field of assembly drums, can solve the problems of increasing length, increasing volume, and being difficult to reach.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

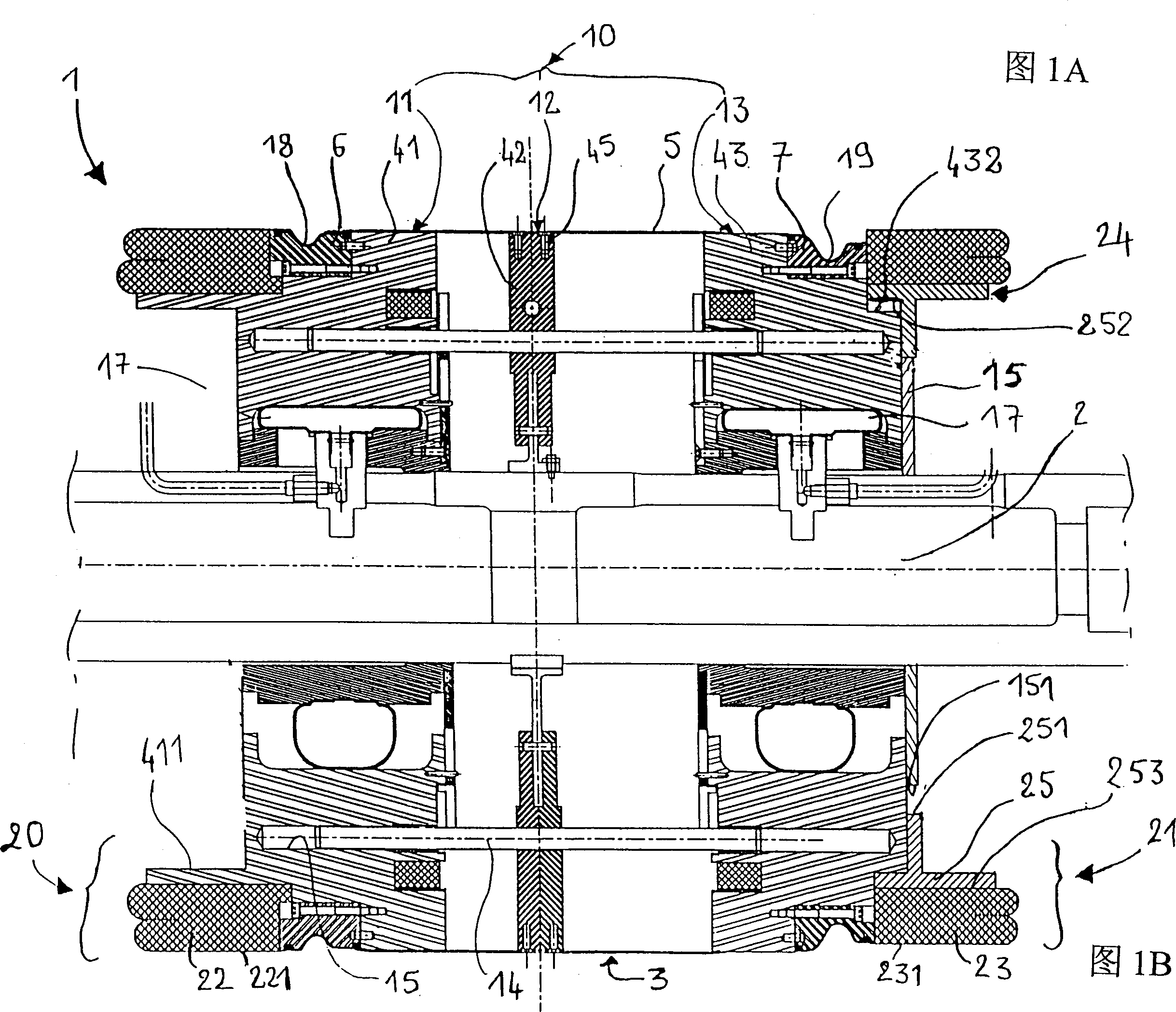

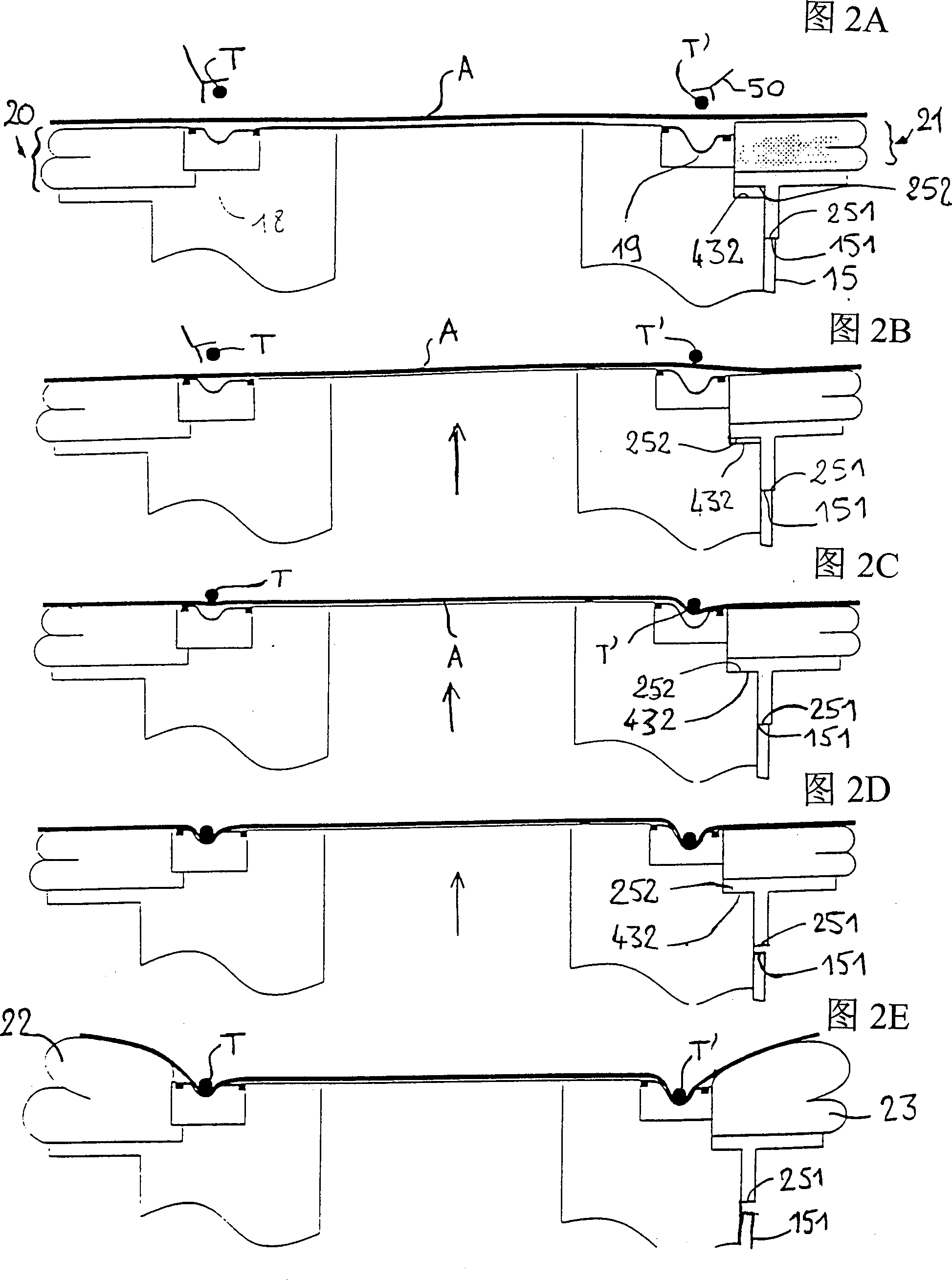

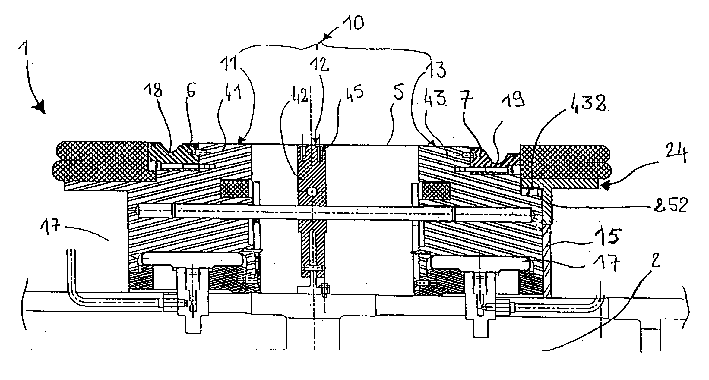

[0016] In FIGS. 1A-1B , a radially expandable assembly drum 1 comprises a main body 10 mounted on a central axis 2 and having a receiving surface 3 for assembled products.

[0017] The main body 10 comprises two semi-cylinders 11 and 13, axially movable around the central axis 2, to adjust the bead wire spacing of the resulting tire, and the two semi-cylinders 11 and 13 are axially fixed relative to the central axis 2 by a central mandrel 12 spaced apart.

[0018] The semi-cylinders 11, 13 and the push rod 12 are respectively composed of a plurality of parts 41, 43 and 42, and the parts 41, 42, 43 are arranged circularly around the central axis 2 and aligned. To ensure the fit of the body 10, each part 41 and 43 is connected to the opposite part 42 by a rod 14 passing through part 42, the ends of which are slidingly fitted in holes 15 in parts 41, 43, respectively.

[0019] To enable the drum 1 to reach its inflated position, the parts 41 , 42 , 43 are radially displaceable u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com