Button switch

A switch and button technology, applied in the structural field of small button switches, can solve the problems of reduced terminal welding range and difficulty in improving welding strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

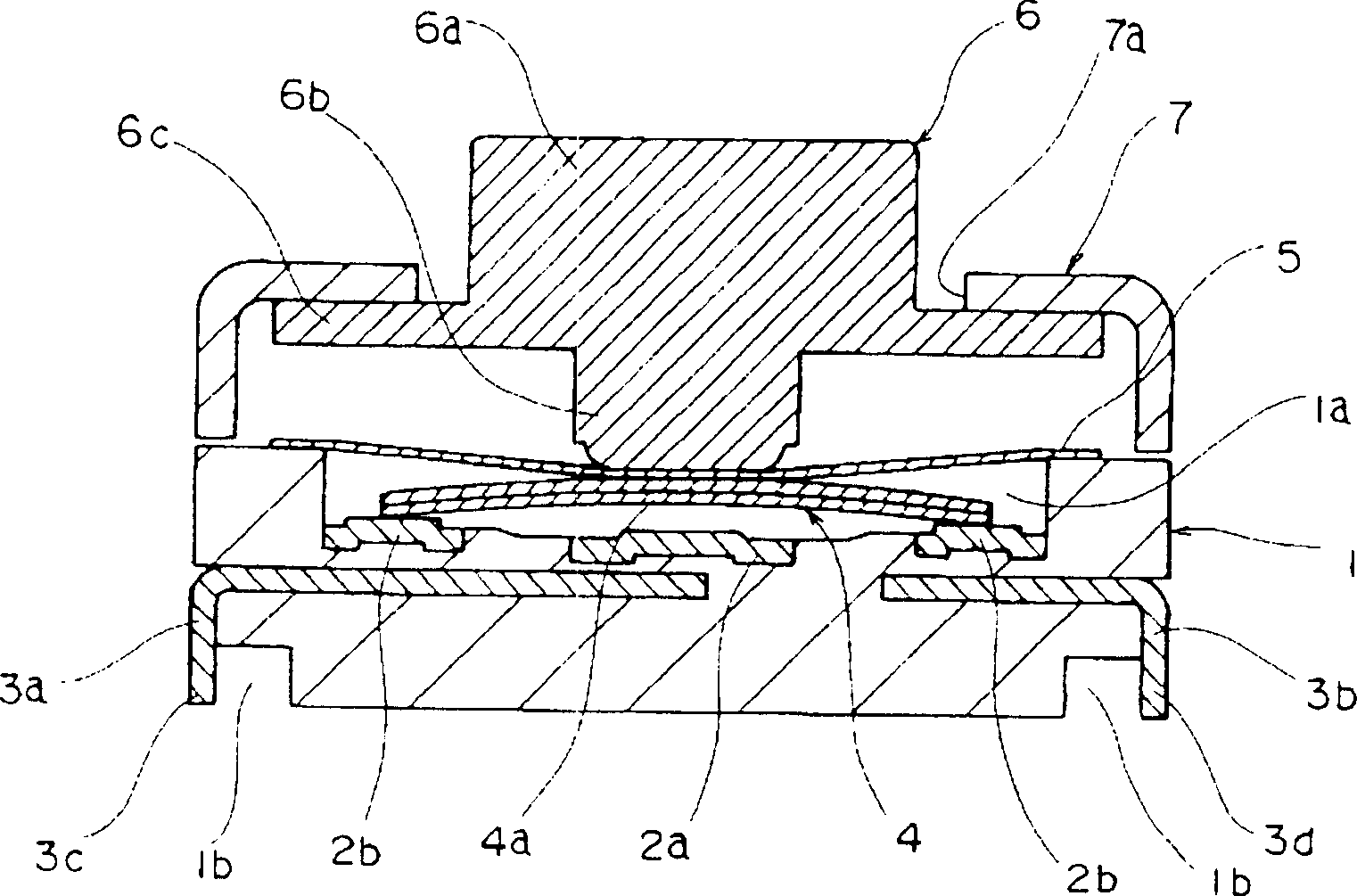

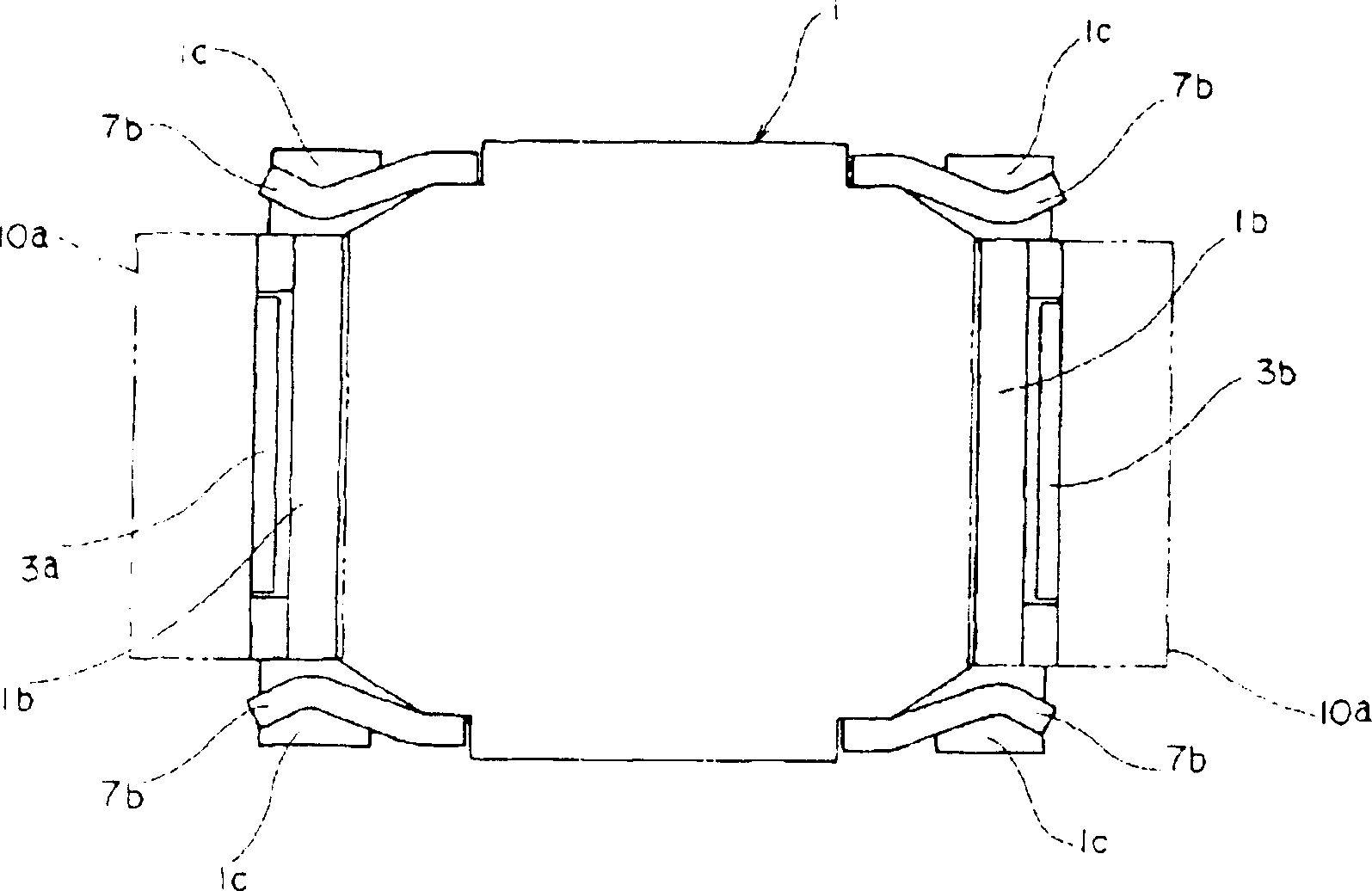

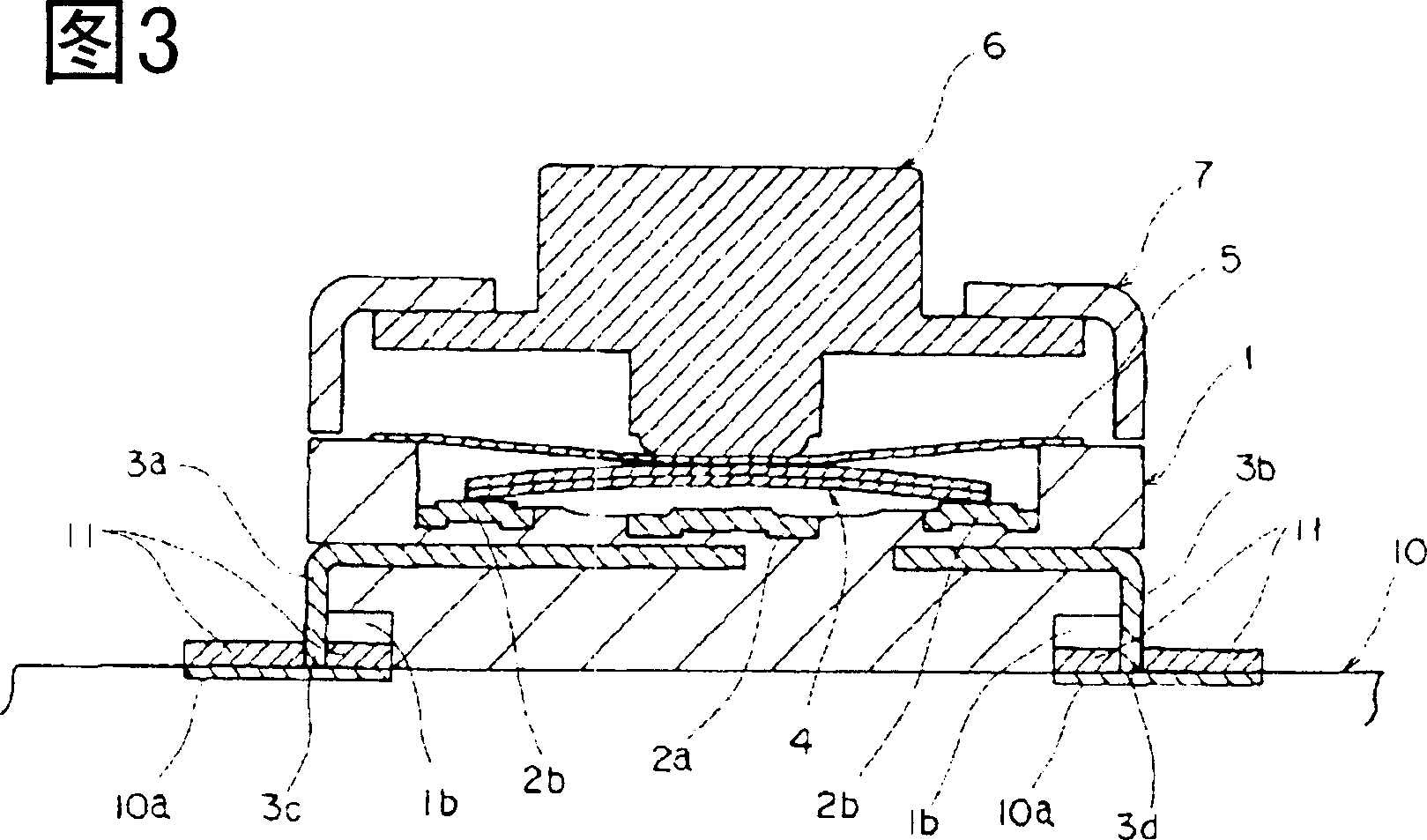

[0030] An embodiment of the push button switch of the present invention is shown in figure 1 ~ Figure 7. Figure 1~Figure 4 Showing one embodiment of the push button switch of the present invention, figure 1 It is a vertical sectional view of the push button switch, figure 2 It is the bottom view of the push button switch. Fig. 3 is a longitudinal sectional view showing the mounting state (before reflow soldering) of the push button switch on the circuit board, Figure 4 It is a longitudinal sectional view of the main part showing the mounting state of the push button switch on the circuit board (after reflow soldering).

[0031] exist figure 1 , figure 2 Among them, the casing 1 is a box-shaped body formed of an insulating material such as synthetic resin, and has an accommodating portion 1a inside, an opening on the top, and a square box shape. At the center of the inner bottom surface of the housing portion 1a of the case 1, a central fixed contact 2a made of conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com