Miniature silicon sapphire differential pressure sensor

A silicon sapphire, sensor technology, applied in pressure difference measurement between multiple valves, instruments, fluid pressure measurement, etc., can solve the failure of silicon piezoresistive pressure difference sensor, contamination of hydraulic oil, failure of servo system to operate normally, etc. problems, to achieve the effect of improving the product's anti-interference ability, convenient installation, and improving the ability to resist space electromagnetic radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

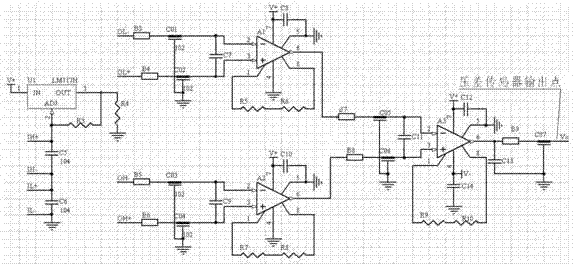

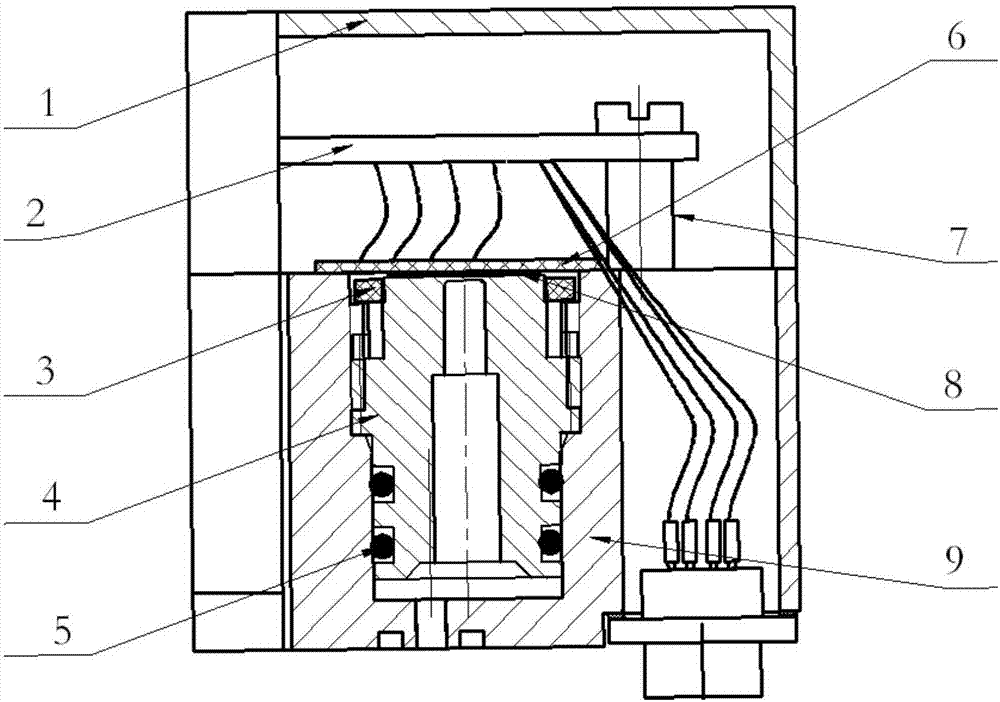

[0027] refer to figure 1 The structure diagram of the small silicon sapphire differential pressure sensor shown in the present invention: the small silicon sapphire differential pressure sensor includes a housing 1, a circuit board 2, an adapter plate 3, a sensitive core 4, a sealing ring 5, a protective cover 6, and a stud 7. Silicon sapphire chip 8, base 9, base 9 is a part of housing 1, wherein, the top of the sensitive core 4 is processed with a metal diaphragm, and a silicon sapphire chip 8 is arranged on the metal diaphragm, and the metal diaphragm and silicon The sapphire chip 8 is sintered at high temperature and connected to the circuit board 2 through the adapter plate 3 and the first wire. The sensitive core 4 is placed in the base 9 as a whole. , the lower section of the sensitive core 4 is a sealing section, which is hermetically connected to the base 9, and the upper end of the base 9 is provided with a protective cover 6 of the sensitive core 4, and the circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com