Non-spheric eccentricity measuring method and device

A measuring device and aspheric surface technology, which is applied in the direction of measuring devices, optical devices, optical instrument testing, etc., can solve the problems of natural measurement accuracy limitations and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

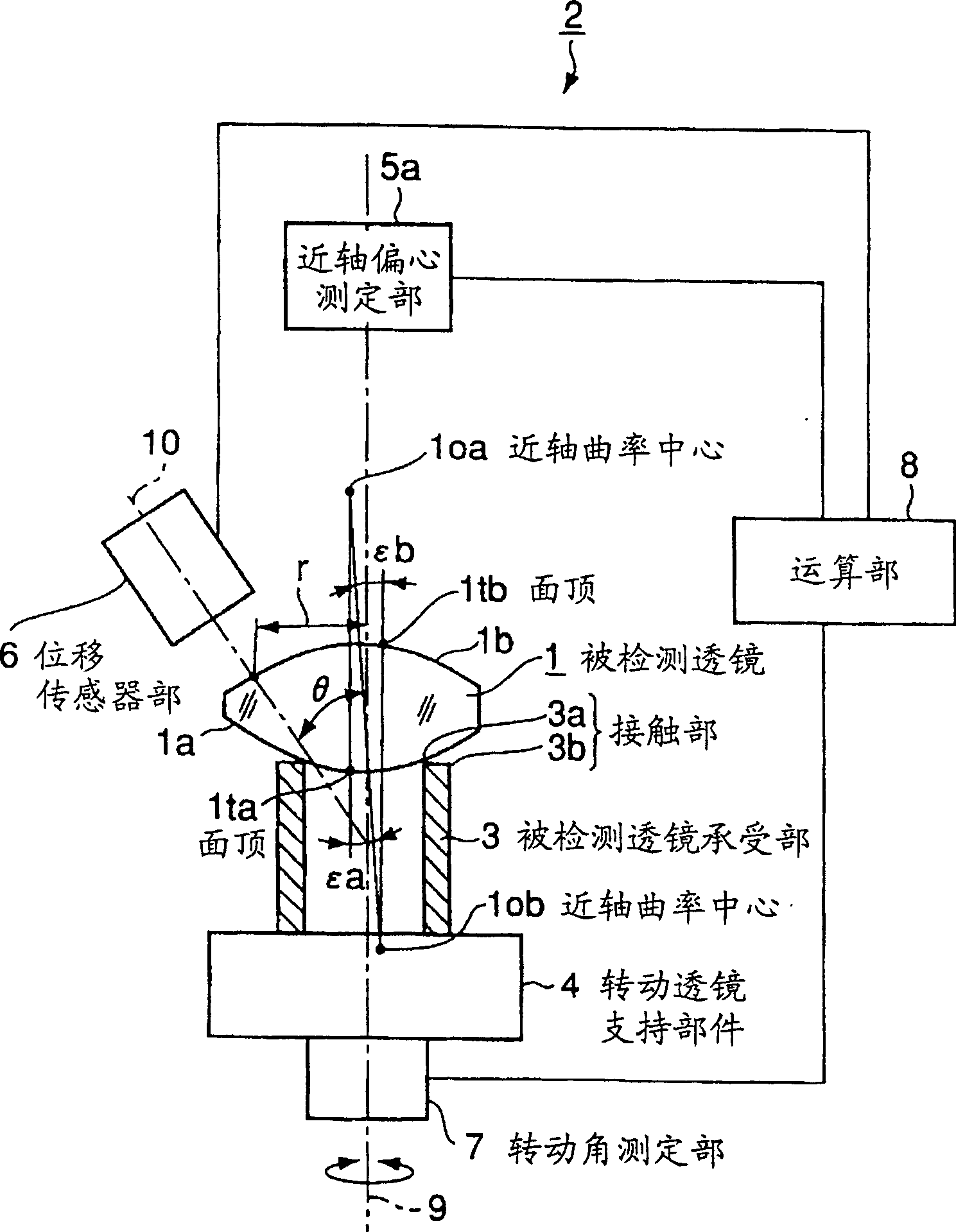

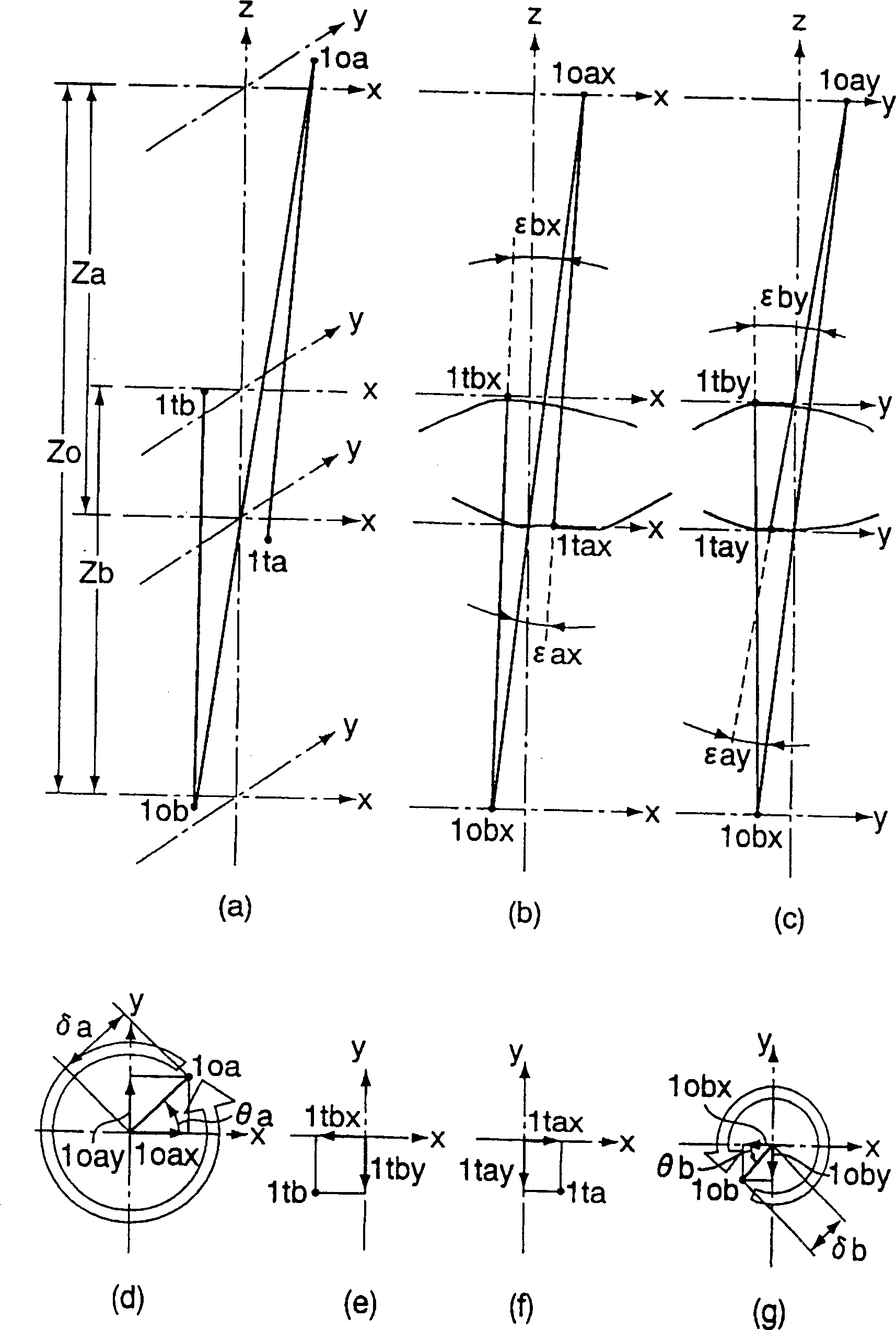

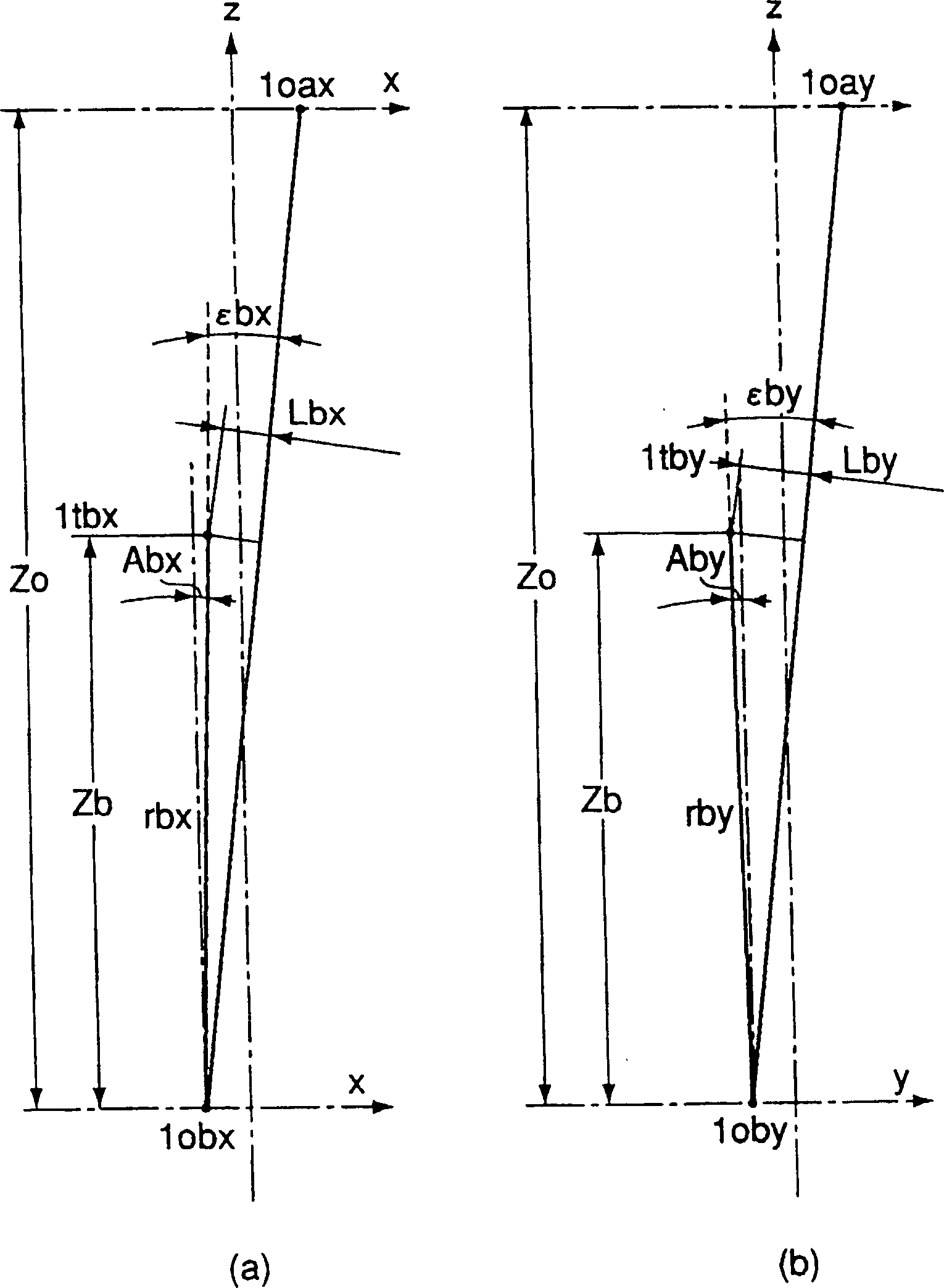

[0042] figure 1 shows the aspheric surface eccentricity measuring device as the first embodiment of the present invention, figure 2 and image 3 A detailed diagram showing the scheme when finding the eccentric value of an aspheric surface. Figure 4 The calculation procedure related to the measurement method of aspheric surface eccentricity is shown as a flow chart. exist figure 1 Among them, the aspheric lens eccentricity measuring device 2 is constituted as follows: the detected lens receiving part 3, which holds the measured object detected lens 1 rotatably; the rotating lens supporting member 4, which is used to rotate the detected lens receiving part 3; The measuring part 5 is used to detect the eccentricity of the paraxial curvature center of the two detected surfaces 1a and 1b of the detected lens 1 with respect to the rotation axis 9 of the rotating lens holding member 4; the detected surface shape measuring part (displacement sensor part) 6. It is used to detec...

Deformed example 1

[0153] exist Figure 5 In , a schematic configuration diagram of an aspheric surface eccentricity measuring device according to a modified example thereof is shown. As shown in the figure, if the detected surface shape measuring part (displacement sensor part) 6 is respectively arranged on the upper and lower sides of the detected lens 1, the inclination amount and direction of the aspheric axis of the receiving surface 1a can be detected without inversion. High-precision measurement of the eccentricity of the upper and lower aspheric surfaces.

[0154] More specifically, in Figure 5 Among them, the composition of the aspheric surface eccentricity measuring device 2 includes: the detected lens receiving part 3, which holds the detected lens 1 freely; the rotating lens supporting member 4, which is used to rotate the detected lens receiving part 3; , used to detect the eccentricity of the paraxial curvature center of the double-sided 1a and 1b of the detected lens 1 with res...

Deformed example 2

[0239] The first embodiment can also be modified and implemented as follows, and achieve the same or better effect than that of the first embodiment.

[0240] Figure 7 is a schematic configuration diagram showing an aspheric surface eccentricity measuring device according to the modification example.

[0241] As shown in the figure, the composition of the aspheric surface eccentricity measuring device 2 includes: a test lens receiving surface 3, which freely rotates to hold the test lens 1; a rotating lens support member 4, which is used to rotate the test lens shown in a vertical section The receiving part 3; the paraxial eccentricity measuring part 5a, which is used to detect the eccentricity of the paraxial curvature center of the reverse surface 1b of the receiving surface 1b of the detected lens 1 with respect to the rotation axis 9 of the rotating lens holding member 4 shown in a vertical section; The axial eccentricity measuring part 5b is used to detect the eccentric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com