Adjustable lens group apparatus

A mirror group and lens technology, which is applied in the field of adjustable mirror group devices, can solve problems such as non-coplanar skew when the transmission cannot be effectively adjusted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

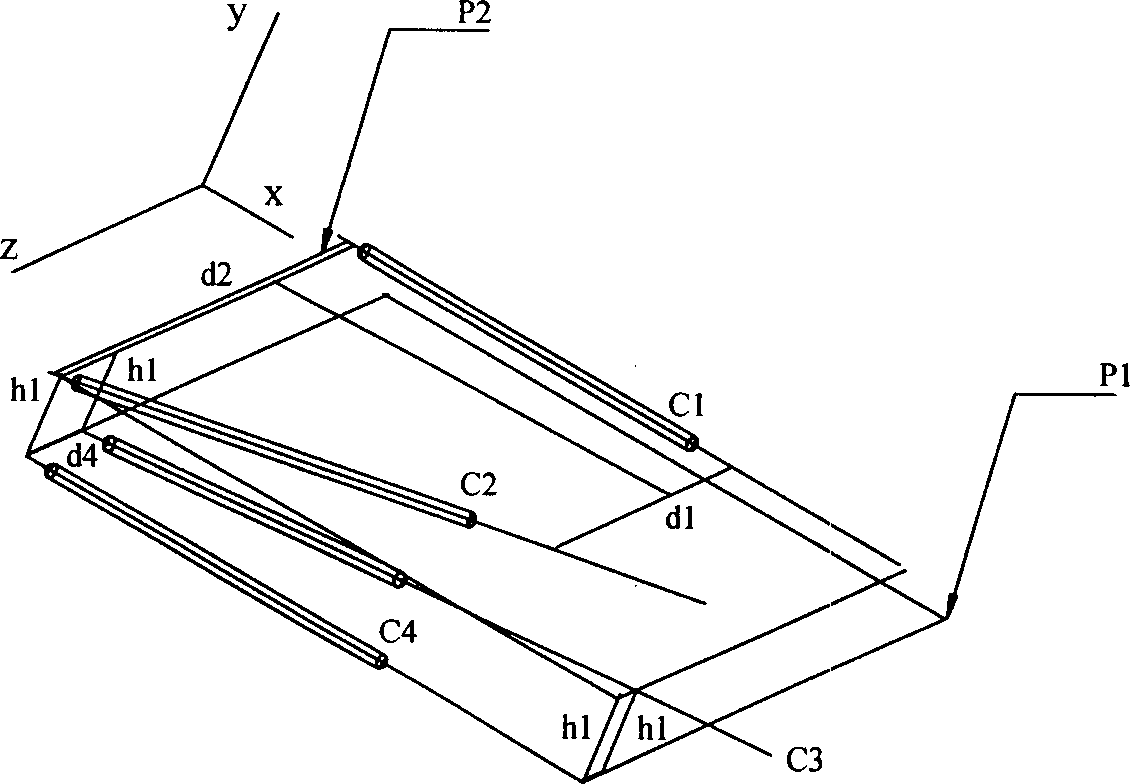

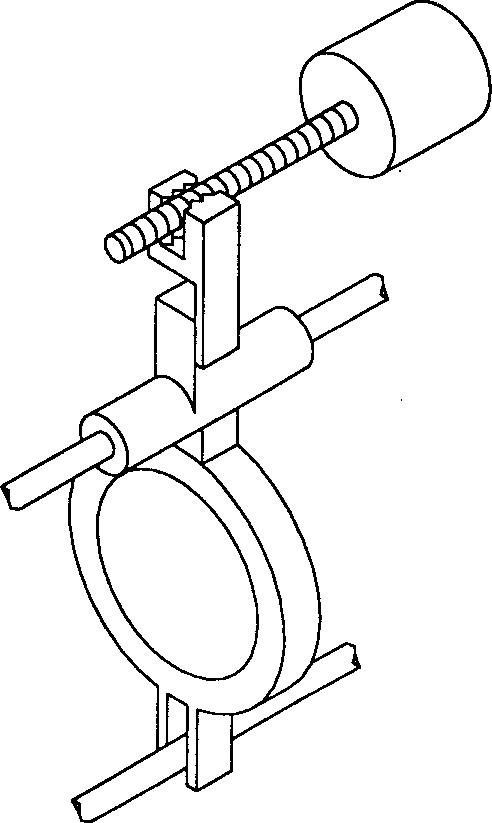

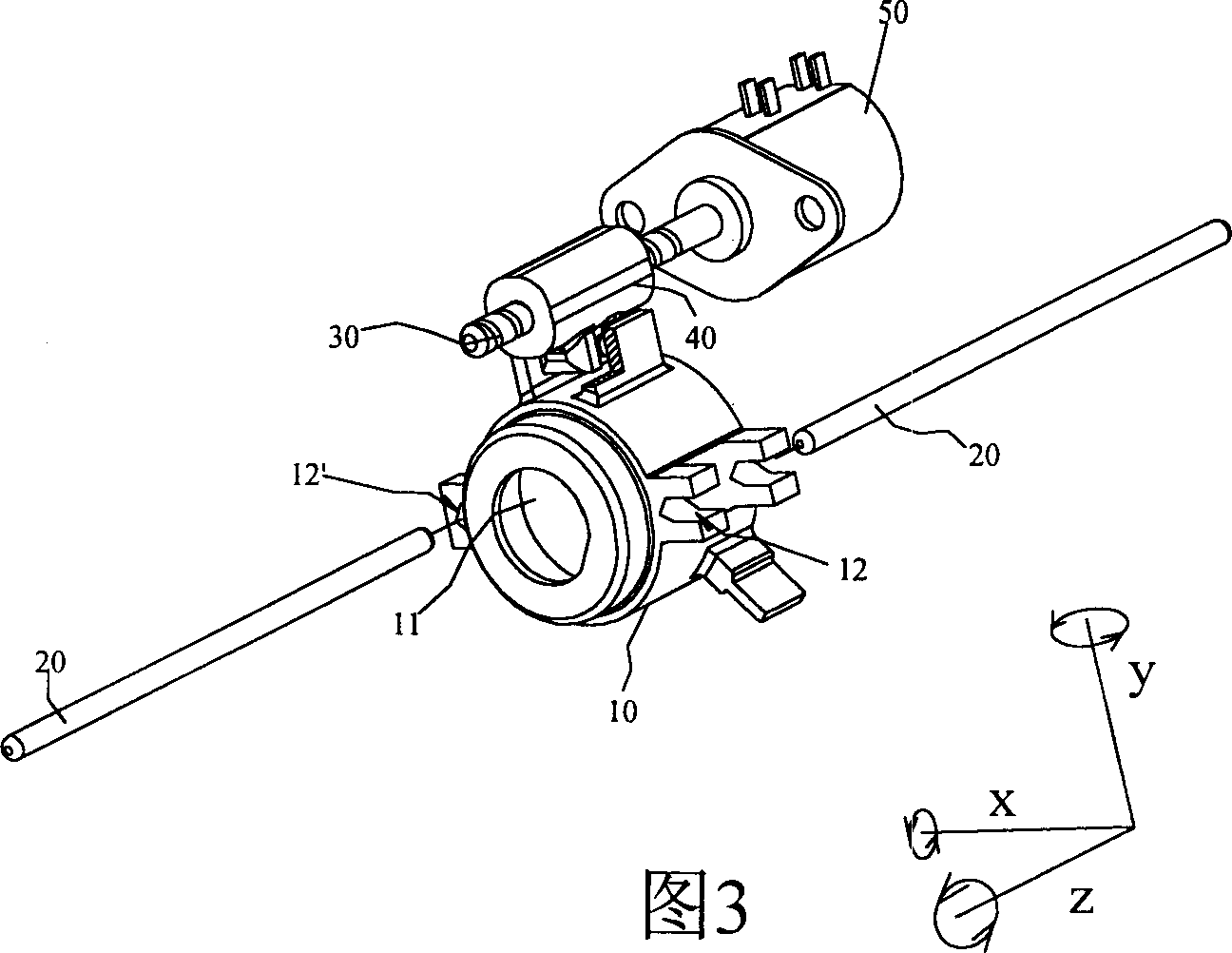

[0041] The adjustable mirror group device of the present invention is a mirror group moving mechanism with a multi-degree-of-freedom adjustment function, to solve the above-mentioned problems, by providing a connecting and engaging mechanism in the mirror group moving mechanism, the driver and the mirror group can be adjusted at any time The position and direction of the driving screw, the driving member and the mirror group are such that even when the driving screw and the optical axis or the guide member (such as a guide rod) are skewed, the mirror group can move smoothly along the optical axis.

[0042] As shown in Figure 3, Figure 4As shown, the adjustable lens group device proposed by the present invention includes a lens group barrel 10, at least one guide member 20, a driving screw 30, a driving member 40, etc.; wherein the driving member 40 is engaged with the driving screw 30 and is The driving screw 30 rotates to make the driving lens group barrel 10 move along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com