Image-formation apparatus

The technology of an imaging device and a heating device is applied in the direction of a printing device, printing, copying/marking method, etc., and can solve problems such as image definition reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

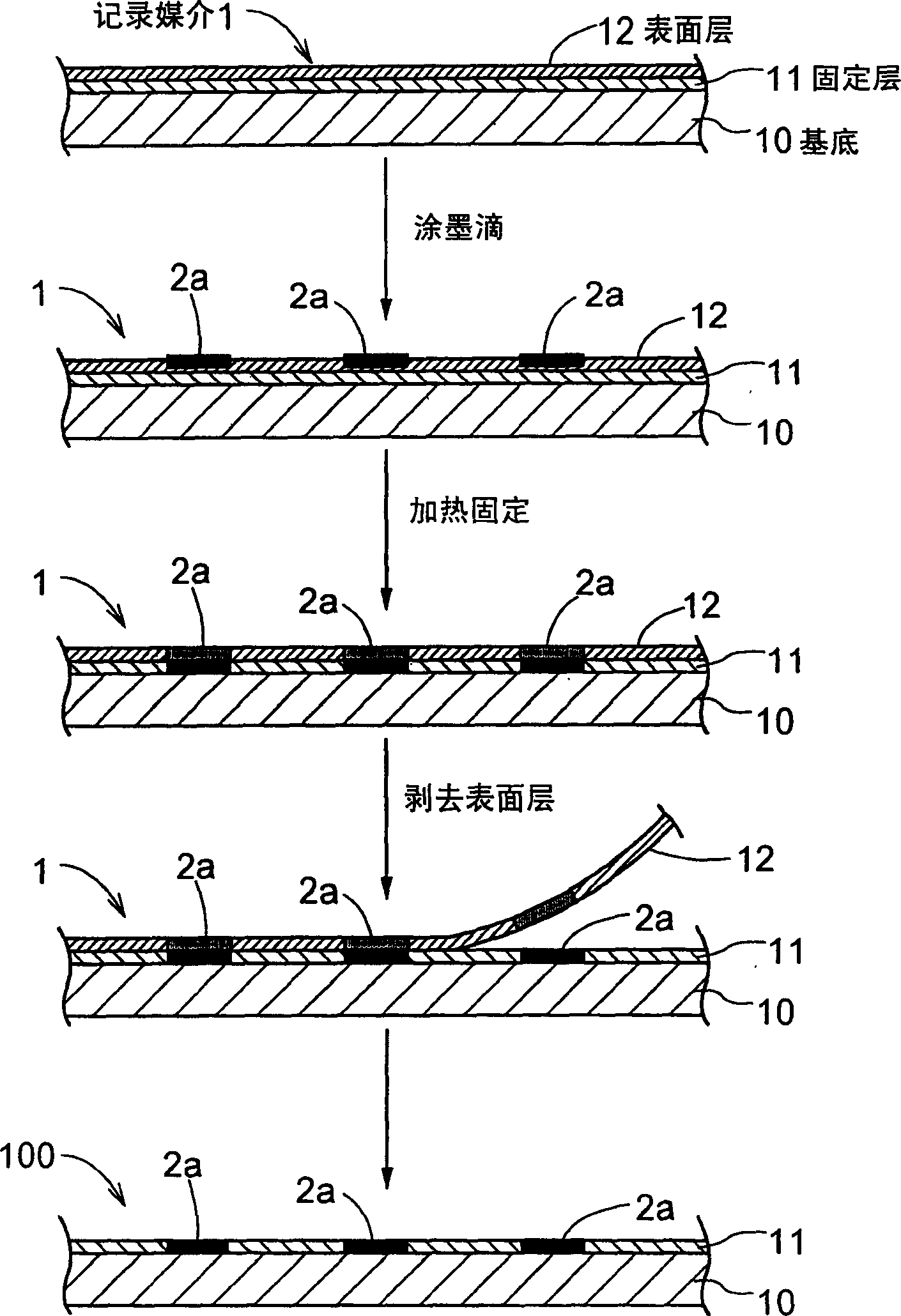

[0055] First refer to figure 1 The recording medium 1 processed by the image forming apparatus of the present invention is described. This recording medium 1 includes a base 10 made of a sheet-like film, for example, a PEG (polyethyleneterephthalate (polyethyleneterephthalate)) sheet-like film, made of a material such as polyurethane resin and positioned on the surface of the base 10 A fixing layer 11 for fixing ink (ie, a colorant of the ink) therein, and a surface layer 12 located on the surface of the layer 11 and serving as a permeable layer allowing ink to permeate therethrough. In the case where the surface of the substrate 10 has properties allowing the colorant of the ink to be directly fixed thereon, the fixing layer 11 may be omitted. In use, droplets of sublimation ink, for example by an inkjet printer, are applied to the surface layer 12 of the recording medium 1 to form a printed image thereon, the printed image consisting of non-sublimated printed dots, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com