Method for fixation between electronic parts

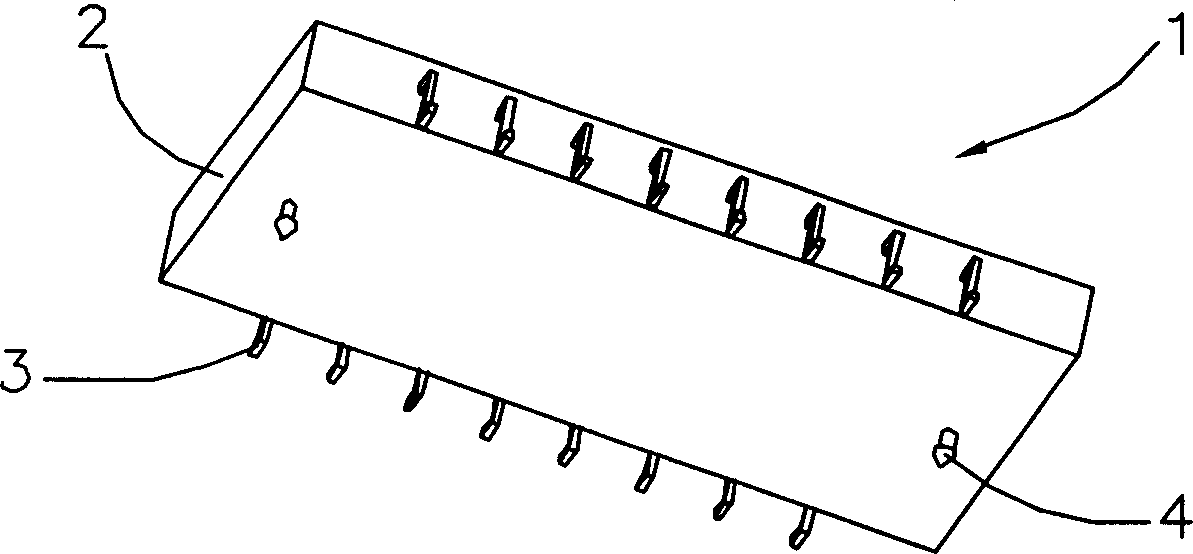

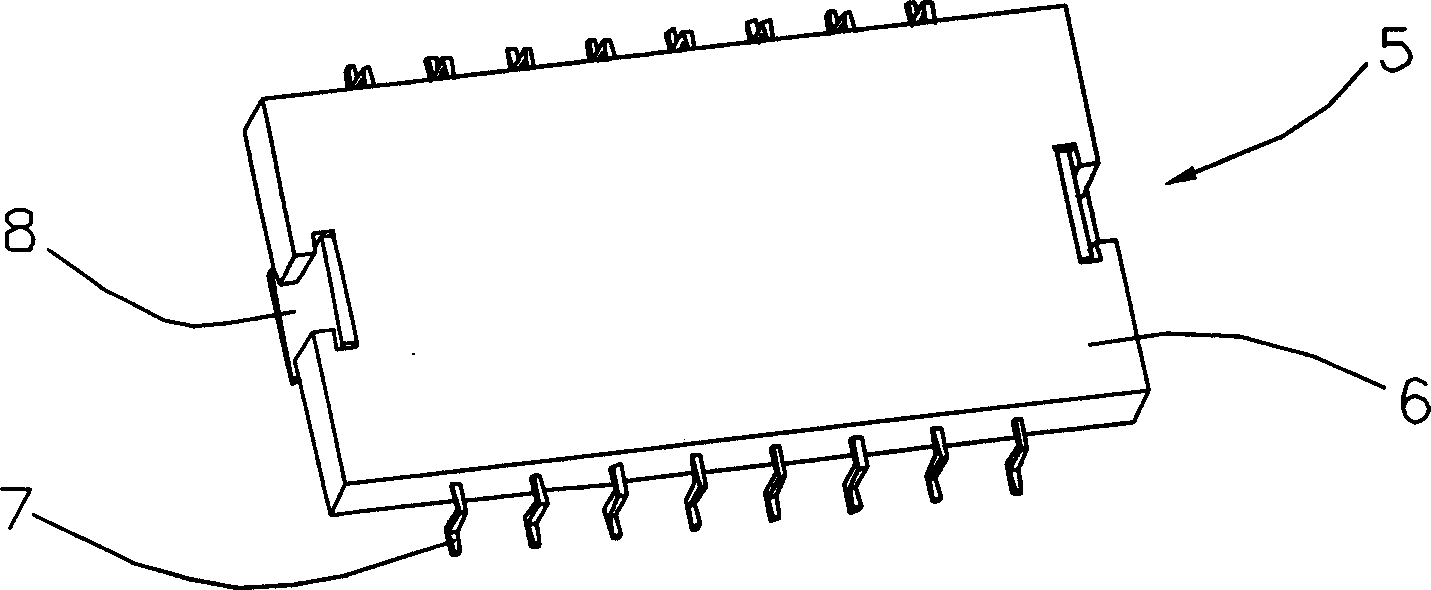

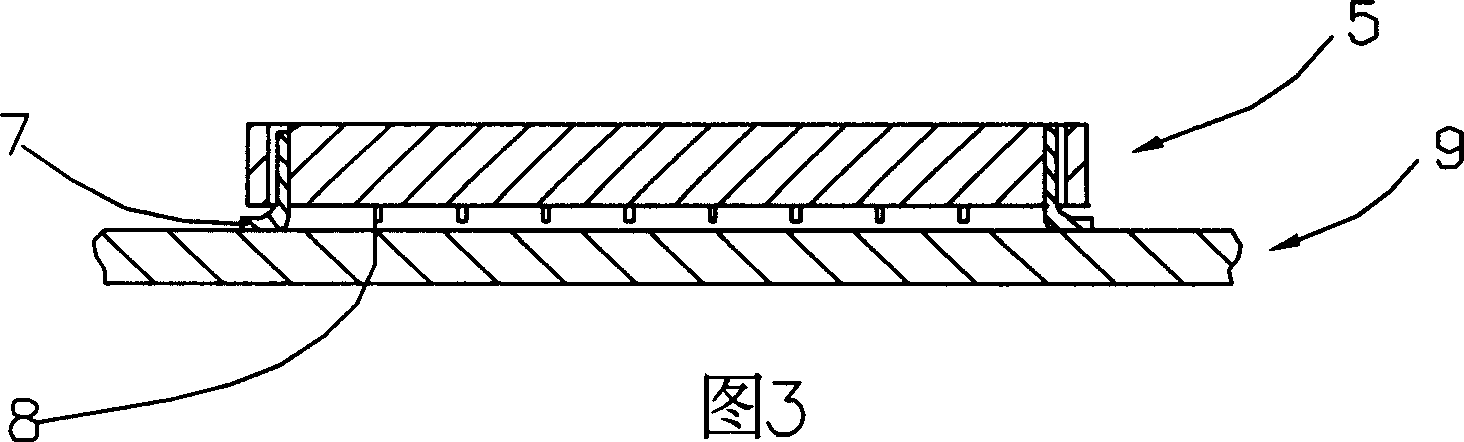

A technology for electronic parts and fixing methods, which is applied in the directions of printed circuit parts, structural connection of printed circuits, and assembling printed circuits with electrical components, which can solve the problem of poor contact between two electronic parts, insufficient fixing force, and difficulty between terminals 7 and metal The sheet body 8 is located on the same plane, etc., to achieve a good fixation effect and save fixation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] 5 and 6 show the first embodiment of the present invention, the first electronic component 10 includes a first body 12 and terminals 14 accommodated in the first body 12, and a surface of the first body 12 There are a plurality of grooves 16 that are roughly in the shape of an inverted trapezoid. The second electronic component 20 includes a second body 22 and solder paste 24 disposed on the body 22 . During assembly, the first electronic component 10 is placed on the second electronic component 20, and then heated at a high temperature. At about 185 degrees Celsius, the solder paste 24 gradually melts into liquid tin. Due to the effect of surface tension, the liquid tin will condense into an approximate spherical so as to enter the groove 16 of the first electronic component 10 . After cooling, the tin liquid will still partially remain in the groove 16, covering the lower edge of the groove 16 (as shown in FIG. 7 ), thereby fixing the first electronic component 10 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com