Stainless steel ball

A technology of stainless steel and steel shot, applied in abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems of easy rust, impact resistance and poor abrasion resistance of steel shot, and achieve short process, improve productivity, equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

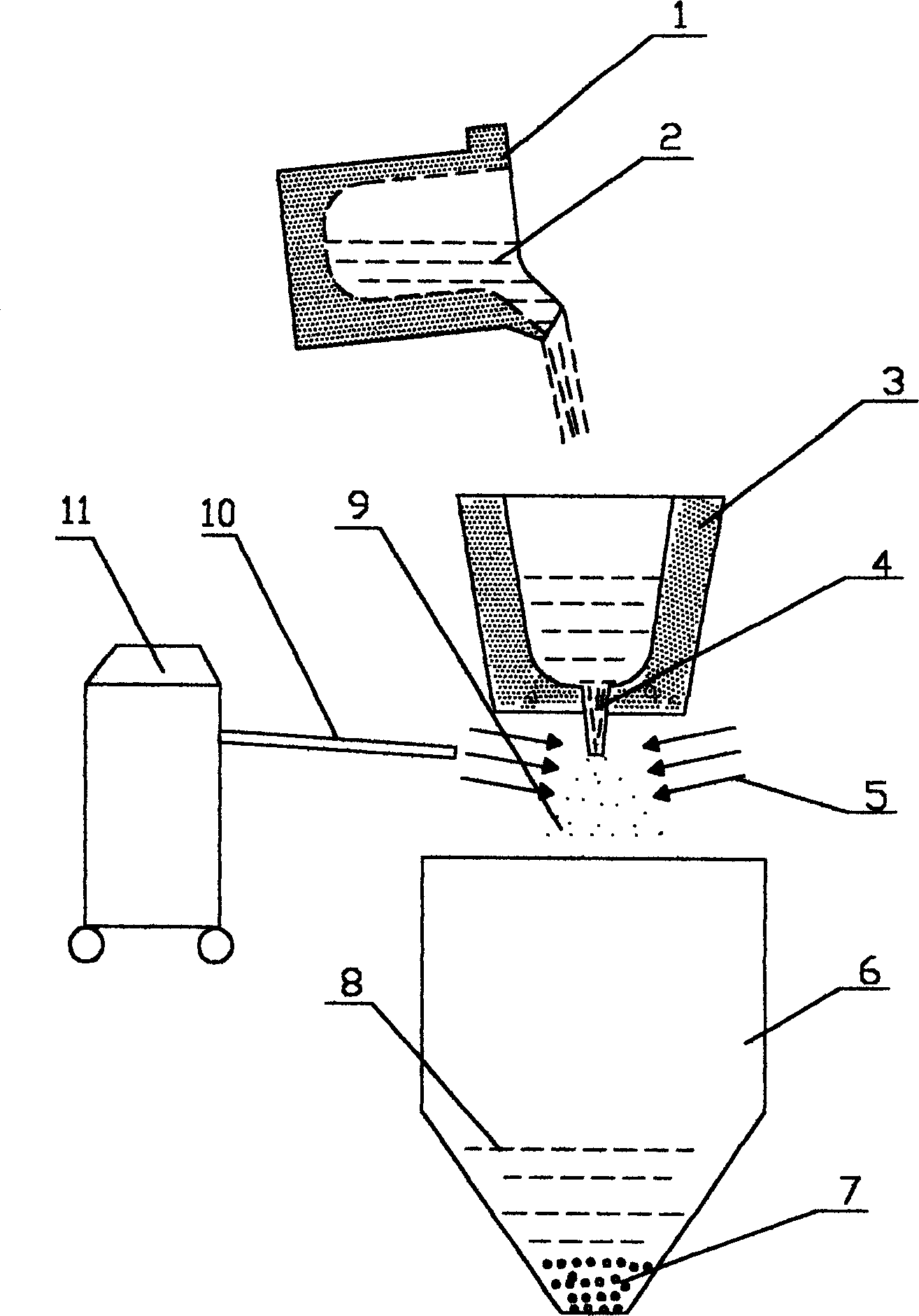

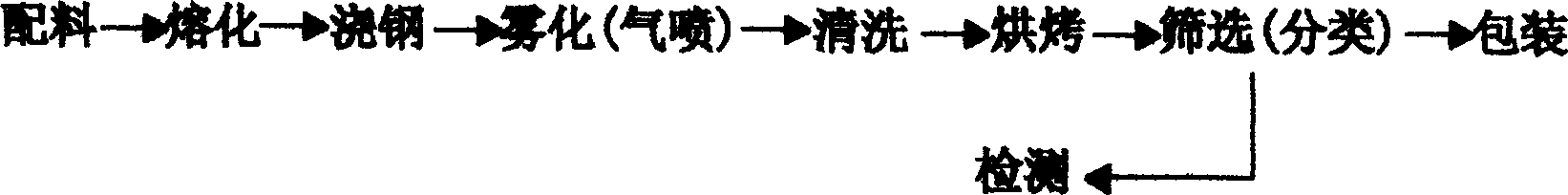

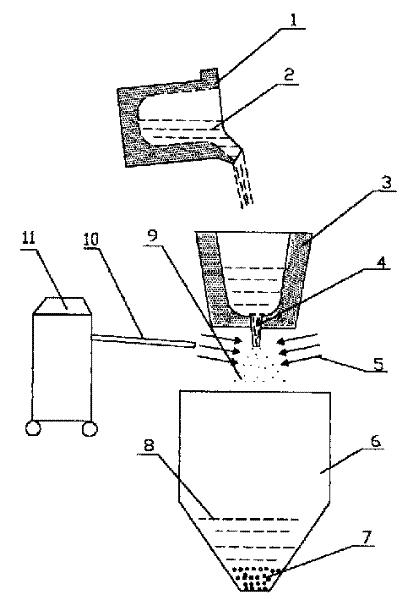

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, said steel shot composition weight percent is:

[0027] Carbon 0.16%

[0028] Silicon 1.6%

[0029] Manganese 1.2%

[0030] Chromium 17%

[0031] Nickel 8%

[0032] Boron 0.6%

Embodiment 2

[0033] Embodiment 2, said steel shot composition weight percent is:

[0034] Carbon 0.2%

[0035] Silicon 1.9%

[0036] Manganese 1.4%

[0037] Chromium 18%

[0038] Nickel 10%

[0039] Boron 1.2%

Embodiment 3

[0040] Embodiment 3, said steel shot composition weight percent is:

[0041] Carbon 0.18%

[0042] Silicon 1.75%

[0043] Manganese 1.3%

[0044] Chromium 17.5%

[0045] Nickel 11%

[0046] Boron 0.6%

[0047] Several indexes relevant to said steel shot of the present invention:

[0048] Microstructure Austenitic

[0049] Hardness (HV)≈470

[0050] Bulk specific gravity ≈4.2kg / dm 3

[0051] Granularity 0~4mm

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap