A blasting method for concrete hollow columns

A concrete and hollow technology, applied in the field of blasting, can solve the problems affecting the quality of blasting holes, blasting without breaking concrete, leakage of blasting gas, etc., achieving high use efficiency, reducing the number of blasting holes, and good hole-forming quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

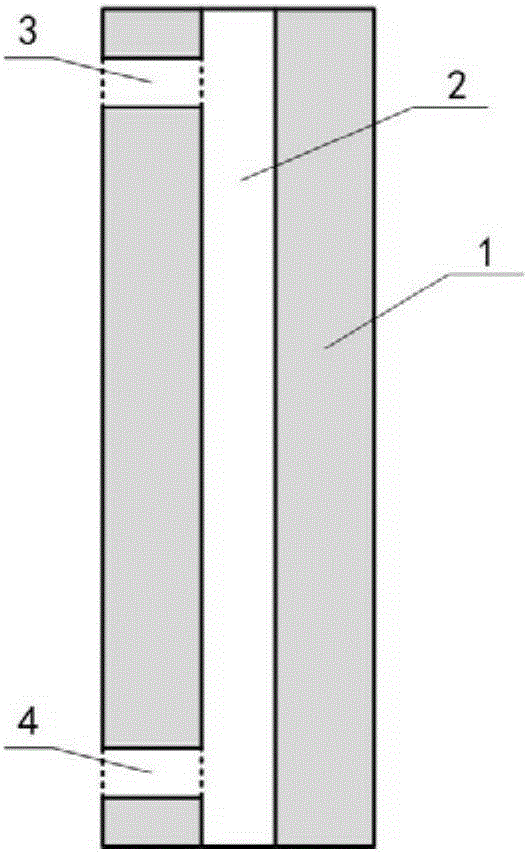

[0021] This embodiment provides a blasting method for a concrete hollow column, which is used for drilling and blasting demolition of a viaduct pier. During the drilling construction process, it was found that the center of the bridge pier is hollow and continuous cavity, so the blasting method of the present invention is adopted, which includes the following steps:

[0022] (1) drill top hole 3 at the top of concrete hollow column 1, top hole 3 to the hollow area 2 of concrete hollow column 1, pour water in hollow area 2, to determine the airtightness of the size of hollow area 2 and hollow area 2;

[0023] (2) Bottom hole 4 is drilled at the bottom of concrete hollow column 1. Bottom hole 4 reaches hollow area 2 of concrete hollow column 1. Water can wash sundries in hollow area 2, and finally drain water in hollow area 2. ;

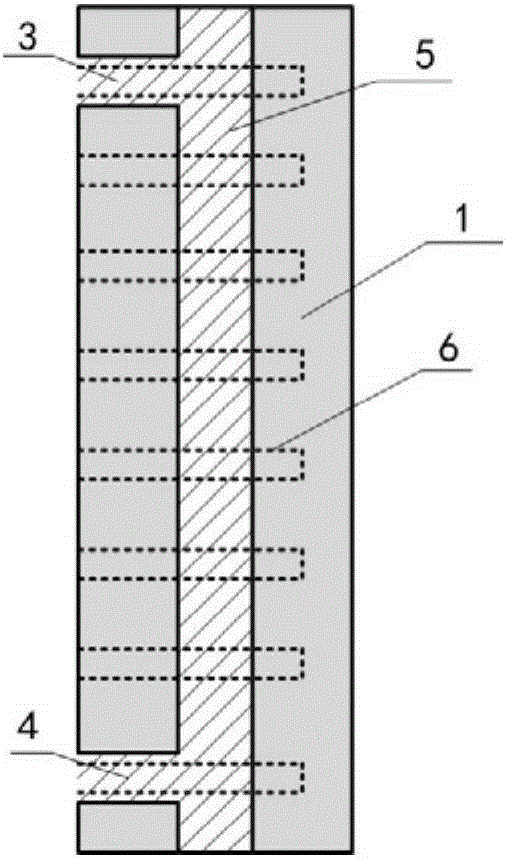

[0024] (3) Inject cement slurry 5 into the hollow area 2 through the top hole 3, and the cement slurry 5 is a mixture of water and cement. When the ...

Embodiment 2

[0027] The difference between this embodiment and embodiment 1 is that the hole diameters of the top hole 3 and the bottom hole 4 are 5 cm.

[0028] The present invention adopts grouting to repair the concrete hollow column 1, which is convenient and fast, and reduces the problem of drilling multiple blast holes due to the influence of the cavity, thus saving construction cost, saving engineering time, and improving construction efficiency; construction equipment and materials are relatively Common, easy to buy, rent and use, and has strong versatility; the repaired concrete hollow column 1 is drilled and drilled with good hole quality, the number of blast holes is significantly reduced, and the blasting efficiency is high; cement is injected into the cavity of the concrete hollow column 1 After the slurry 5 is solidified, it has good adhesion with the original concrete material, which is beneficial to the uniform crushing of the concrete hollow column 1 by explosive placement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap