Optical recording medium

An optical recording medium, optical recording technology, applied in optical recording carrier, optical recording carrier manufacturing, recording/reproducing by optical method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

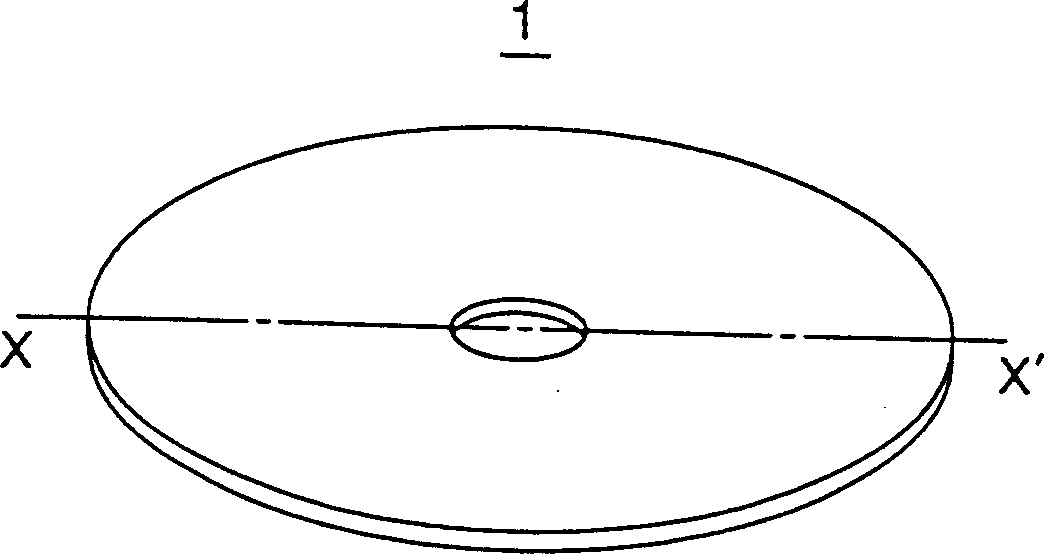

[0052] Fig. 2A is a perspective view of an optical disc according to this embodiment, and Fig. 2B is a sectional view taken along X-X' in Fig. 2A.

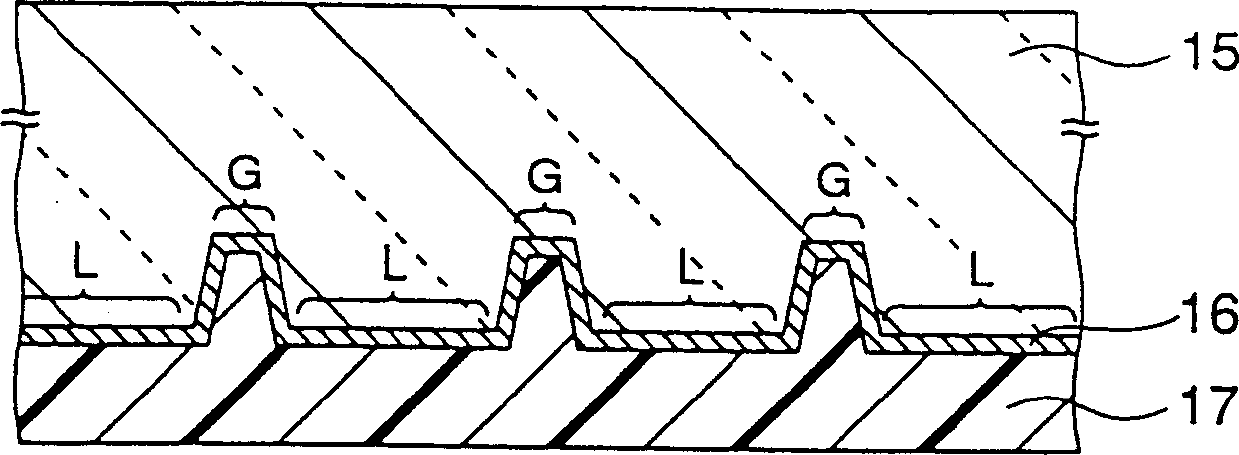

[0053] An optical disc 1 has a lamination of a disc substrate 15, an optical recording layer 16, and a protective layer 17, and has an approximately disc-shaped mold with an opening at its center.

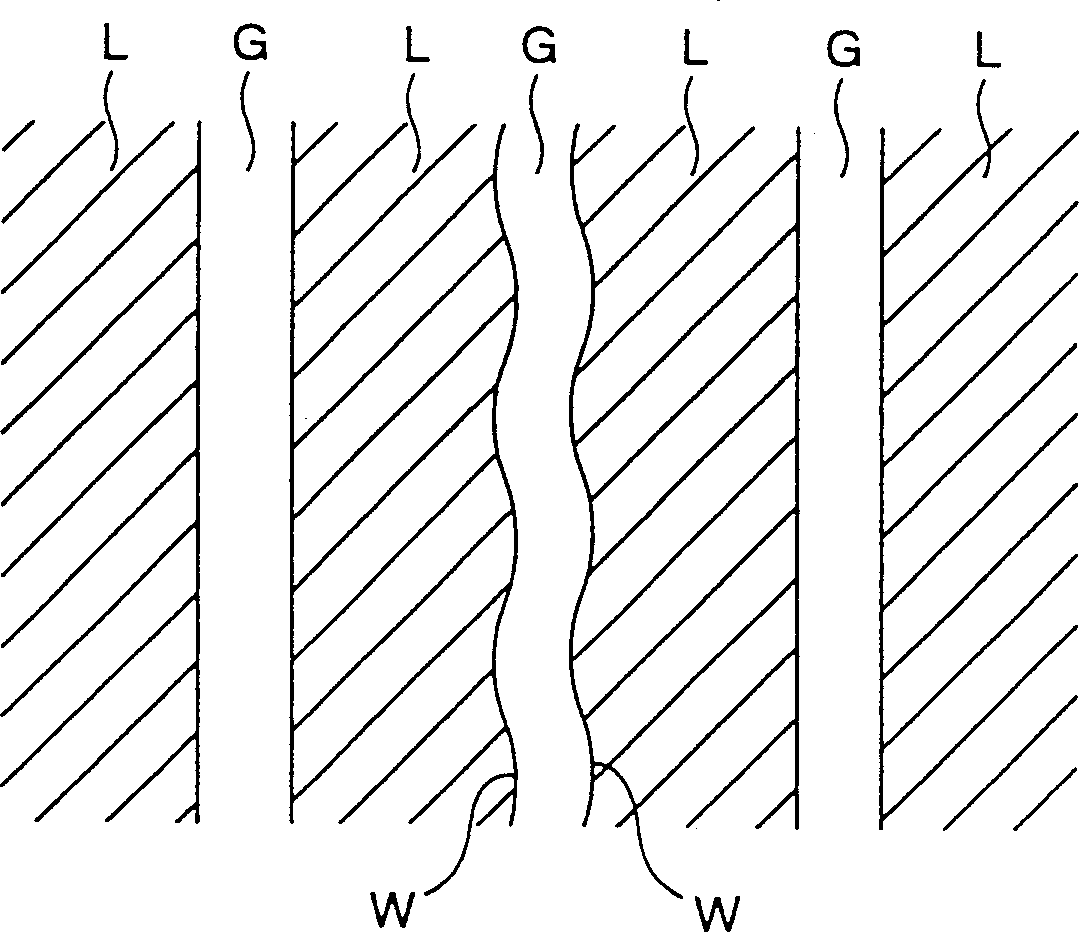

[0054] Figure 3A is a diagram showing the Y corresponding to Figure 2B 1 A magnified view of a part of the cross-sectional structure and a schematic of the method of focusing light. In this figure, the right side is the inner circumferential side of the disc, and the left side is the outer circumferential side.

[0055] The chute surface 15a is provided on one surface of the disk substrate 15 having a thickness D1 of 1.1 to 1.2 mm. An optical recording layer 16 includes, for example, an insulating film, a recording film, another insulating film, and a reflective film, which are stacked in this order on the surface. The configuration...

no. 2 example

[0116] An optical disc of the present invention in the same manner as the first embodiment shown in FIG. 2 has a laminate of a disc substrate, an optical recording layer and a protective layer, and has an approximate disc shape with an opening portion at its center.

[0117] Fig. 9 is a plan view of the optical disc according to the present embodiment.

[0118] First chute surfaces 15a are alternately provided on one surface of a disk substrate 15 whose thickness is 1.1 to 1.2mm 1 And than the first chute surface 15a 1 Deeper second chute surface 15a 2 . On this surface is formed an optical recording layer in which, for example, an insulating film, a recording film, another insulating film and a reflection film are laminated in this order. The configuration of the film and the number of layers may vary depending on the type and design of the recording material.

[0119] A protective layer 17 is formed on the optical recording layer 16 .

[0120] On the optical disc as des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com