Electrophotographic photoreceptor, electrophotographic member, process cartridge and image forming apparatus

An electrophotographic and photoreceptor technology, which is applied in the fields of electrophotographic photoreceptors, electrophotographic components, developing toner drums and image forming apparatuses, and can solve problems such as difficulty in removing, increasing surface contamination, and reducing toner adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0274] Then, 100 parts by weight of the above carrier and 5 parts by weight of Toner 1 were stirred with a V-blender at 40 rpm for 20 minutes, and sieved with a sieve having an aperture of 212 μm to obtain Developer 1 (black, cyan, magenta). 4 colors of red and yellow). (preparation of electrophotographic photoreceptor A)

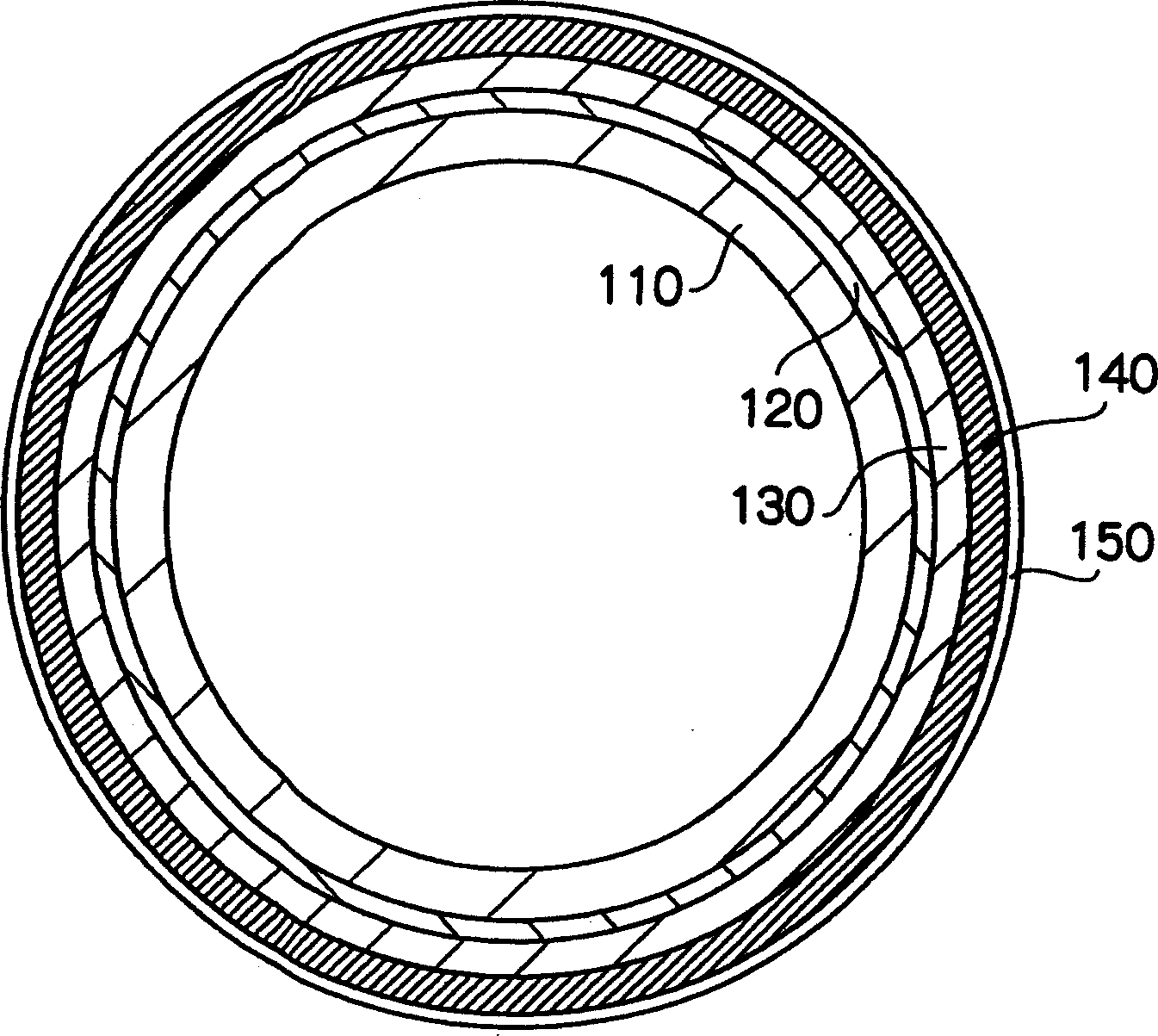

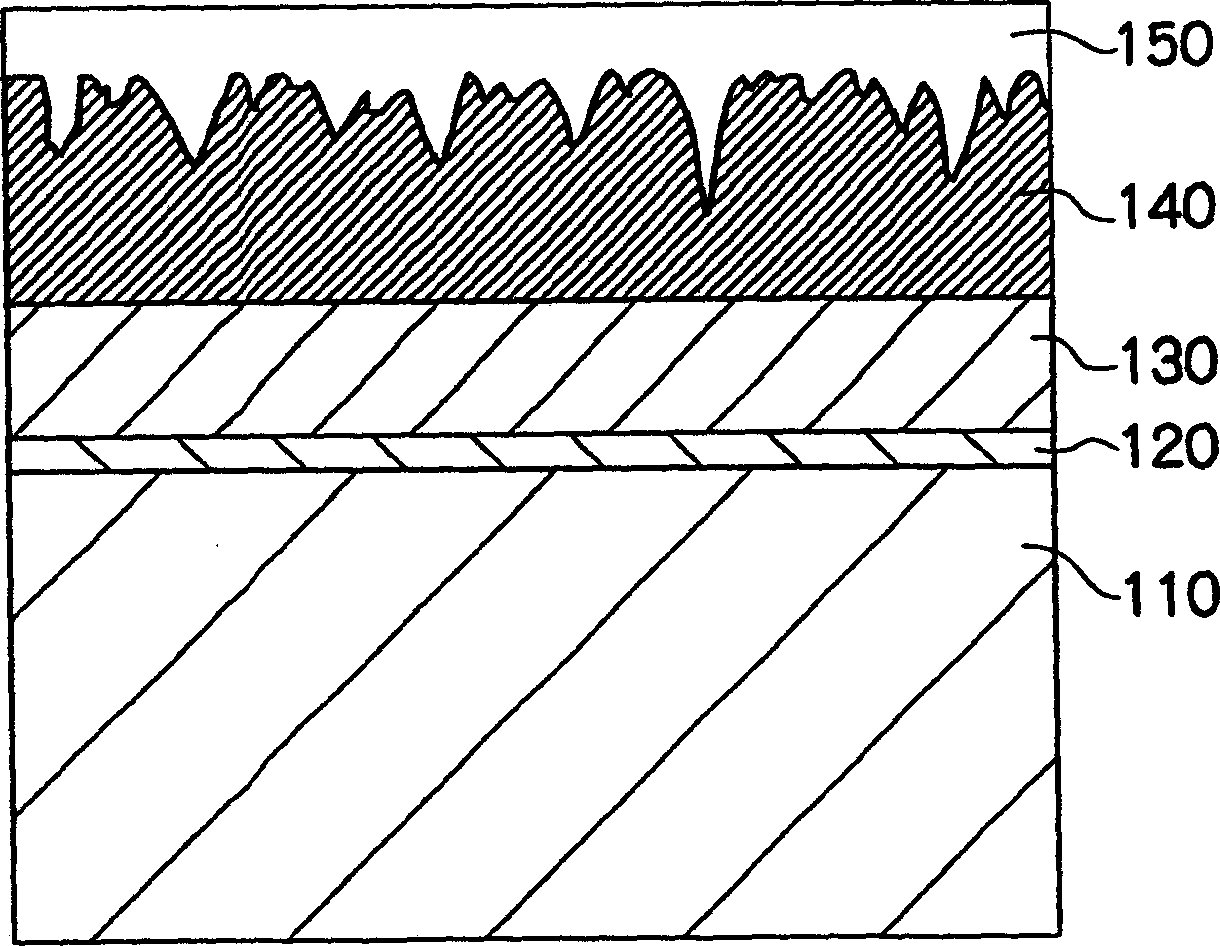

[0275] The surface of the cylindrical aluminum-based part (conductor support) with an outer diameter of 30 mmφ that has been honed is coated with 10 parts by weight of a zirconium compound (trade name: Orgatics ZC 540, produced by Matsumoto Chemical Industry Co. , Ltd.), 1 part by weight of a silane compound (trade name: A1100, by Nippon Unicar Company Limited), 40 parts by weight of isopropanol and 20 parts by weight of butanol, the coating was heated and dried at 150°C 10 minutes, thereby forming a base layer having a film thickness of 0.1 µm.

[0276] Next, in 100 parts by weight of butyl acetate, add 1 part by weight of gallium chloride which has str...

Embodiment 2

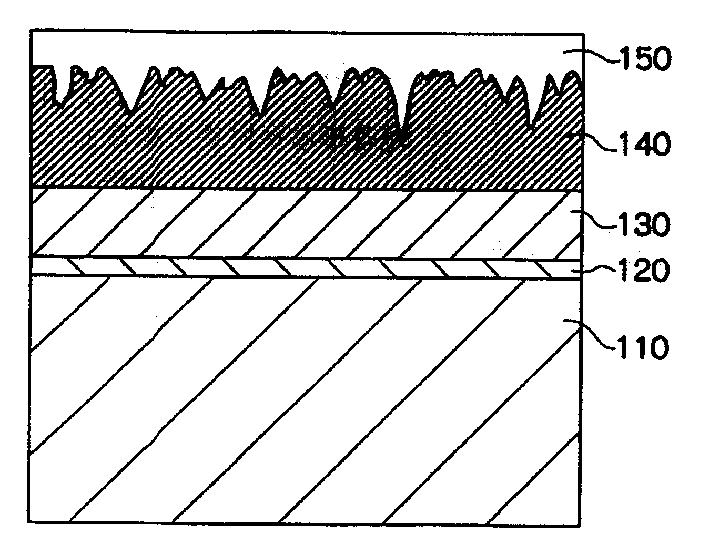

[0297] As a result, no problem occurred with respect to the images on the initial copy and the 50,000th copy under any environmental conditions, and no abnormalities such as scratches, pinholes and toner adhesion were found on the photoreceptor surface. In addition, the torque of the photoreceptor was 0.12 N.m after the 50,000 copy durability test, and the water contact angle of the photoreceptor surface was 102°, thus maintaining excellent release performance. (preparation of electrophotographic photoreceptor B)

[0298] The surface of the cylindrical aluminum-based part (conductor support) with an outer diameter of 80 mmφ that has been honed is coated with 10 parts by weight of a zirconium compound (trade name: Orgafics ZC 540, produced by Matsumoto Chemical Industry Co. , Ltd.), 1 part by weight of a silane compound (trade name: A1100, by Nippon Unicar Company Limited), 40 parts by weight of isopropanol and 20 parts by weight of butanol, the coating was heated and dried at...

Embodiment 3

[0320] As a result, no problem occurred with respect to the images on the initial copy and the 100,000th copy under any environmental conditions, and no abnormalities such as scratches, pinholes and toner adhesion were found on the photoreceptor surface. In addition, the torque of the photoreceptor after the 100,000 copy durability test was 0.18 N·m, and the water contact angle of the photoreceptor surface was 98°, thus maintaining excellent release performance. (preparation of cleaning blade (cleaning member))

[0321] A urethane material was poured into a mold and heated to form a blade-shaped product (JIS A hardness: 75°) of 330 mm in length, 20 mm in width, and 2 mm in thickness. In this manner, a fluorine-containing resin layer was formed on the surface of the formed urethane blade by using the vacuum-dipping method described below.

[0322] Firstly, put the obtained urethane blade into a vacuum oven, reduce the pressure of the oven to a vacuum degree of 0.02 MPa, and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com