Collapsible freestanding reusable container for carrying plate glasses

A flat glass, turnover box technology, applied in transportation and packaging, sustainable manufacturing/processing, packaging of vulnerable items, etc., can solve problems such as poor compression resistance, slippage, and unsatisfactory stacking stability of turnover boxes , to achieve the effect of safety performance guarantee and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

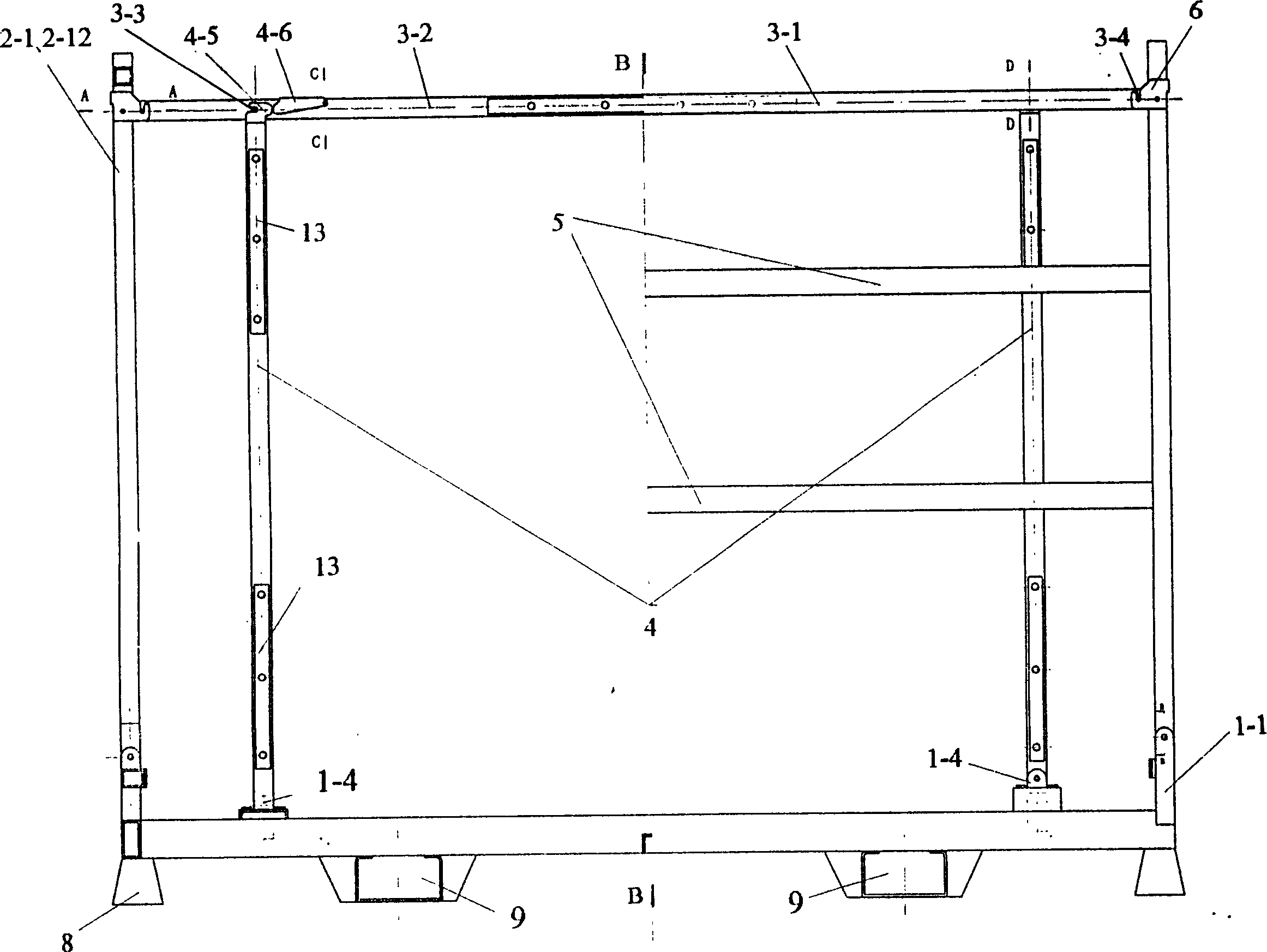

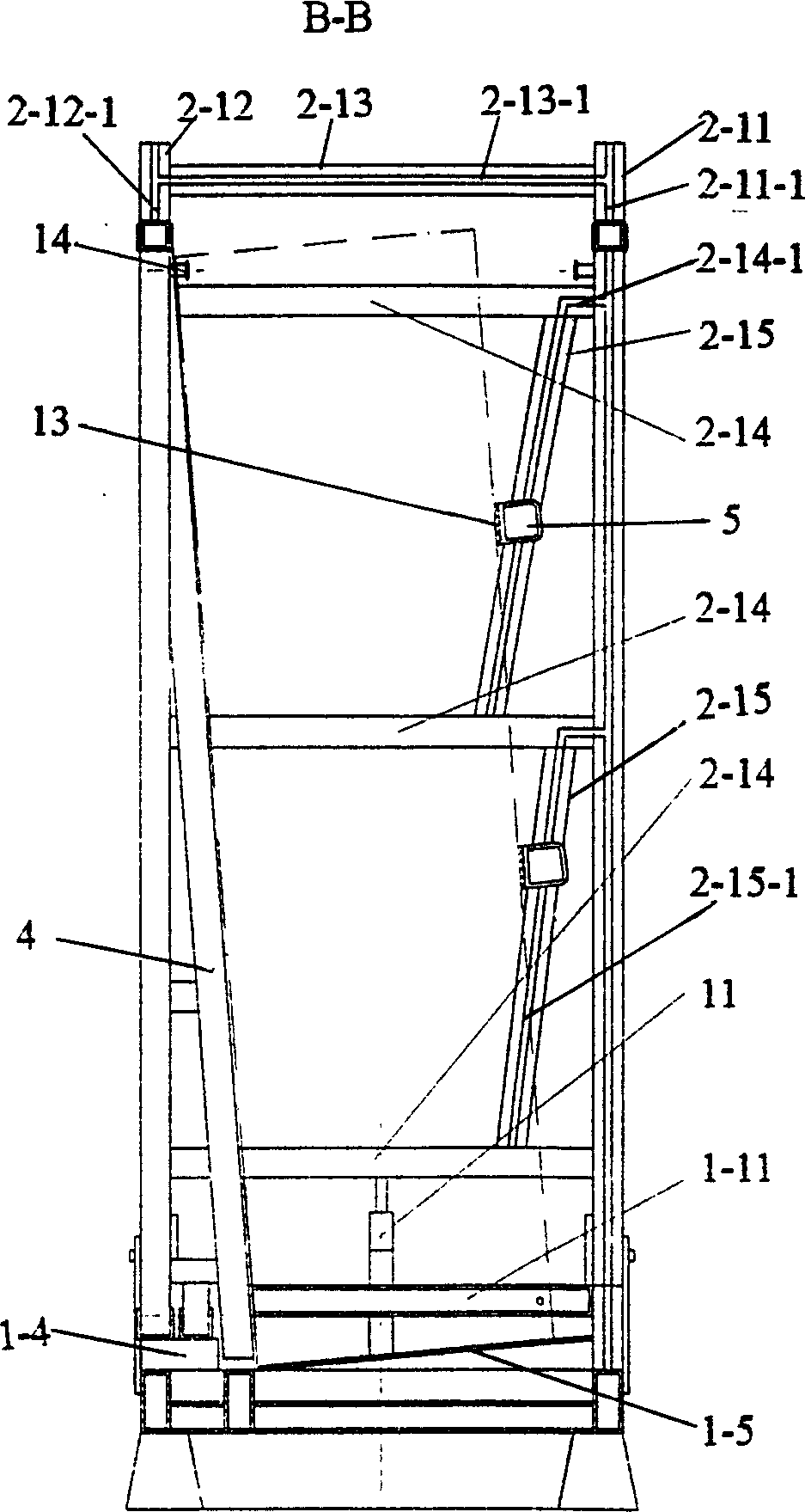

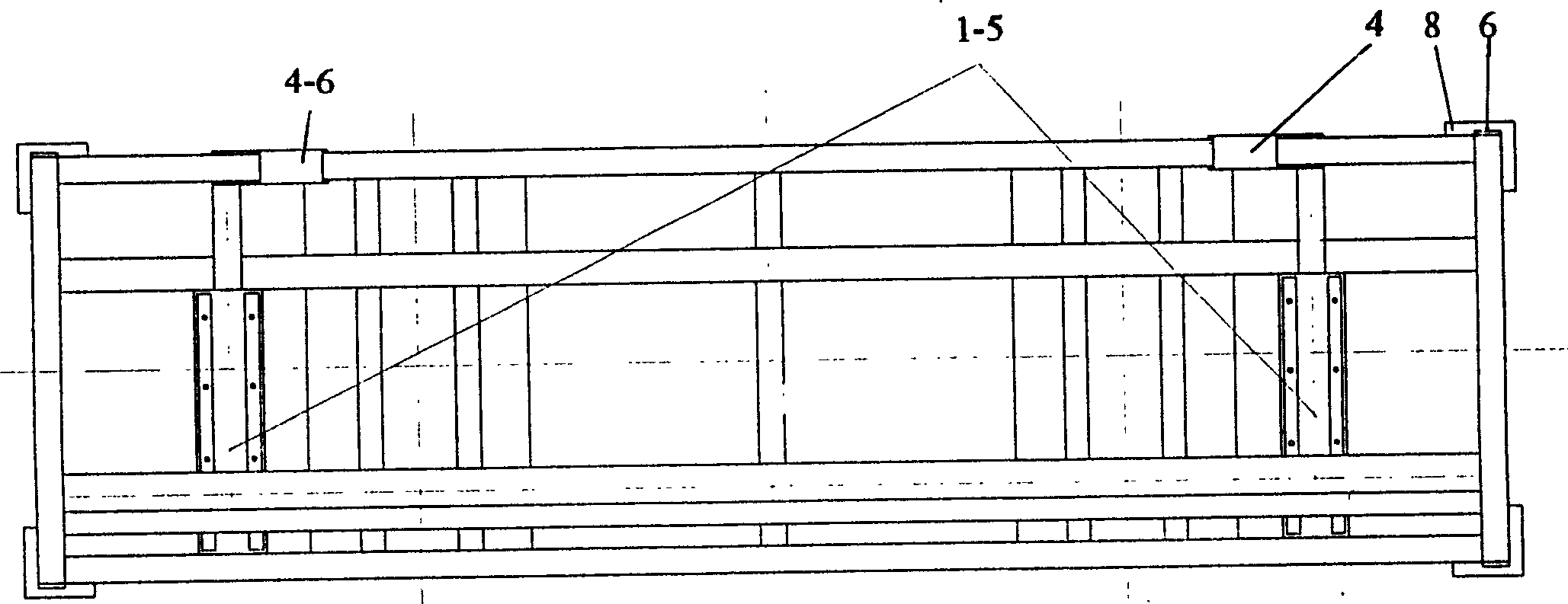

[0037] Figure 1~3 Shown, embodiment has bottom frame 1 and two sides frame 2-1, and two sides frame 2-1 respectively has front pole 2-11, rear pole 2-12 and is connected in front and rear pole 2-11, The side upper cross bar 2-13 and the side middle cross bar 2-14 of 2-12, the front and rear vertical bars 2-11, 2-12 stretch out the side upper cross bar 2-13, between the two side frames 2-1 There are two compression rods 5, and each side frame is provided with two side-slanting rods 2-15 corresponding to the compression rods 5 and inclined backward and downward. Since the side-slanting rods 2-15 are connected to the same side frame Between the middle cross bars 2-14 on both sides, so the side frame 2-1 has three side middle cross bars 2-14. Side upper cross bar 2-13, side middle cross bar 2-14, side slant bar 2-15, front upright bar 2-11, and rear upright bar 2-12 are generally made of "C" type steel pipes, and "C" type The opening mouth of steel pipe promptly forms guide gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com