Elevator balance weight

A technology of elevators and counterweights, which is applied to elevators in buildings, elevators, and lifting equipment in mines, etc. It can solve the problems of wasting installation space, increasing the types of components, and extending the length of parts, so as to save space and achieve flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

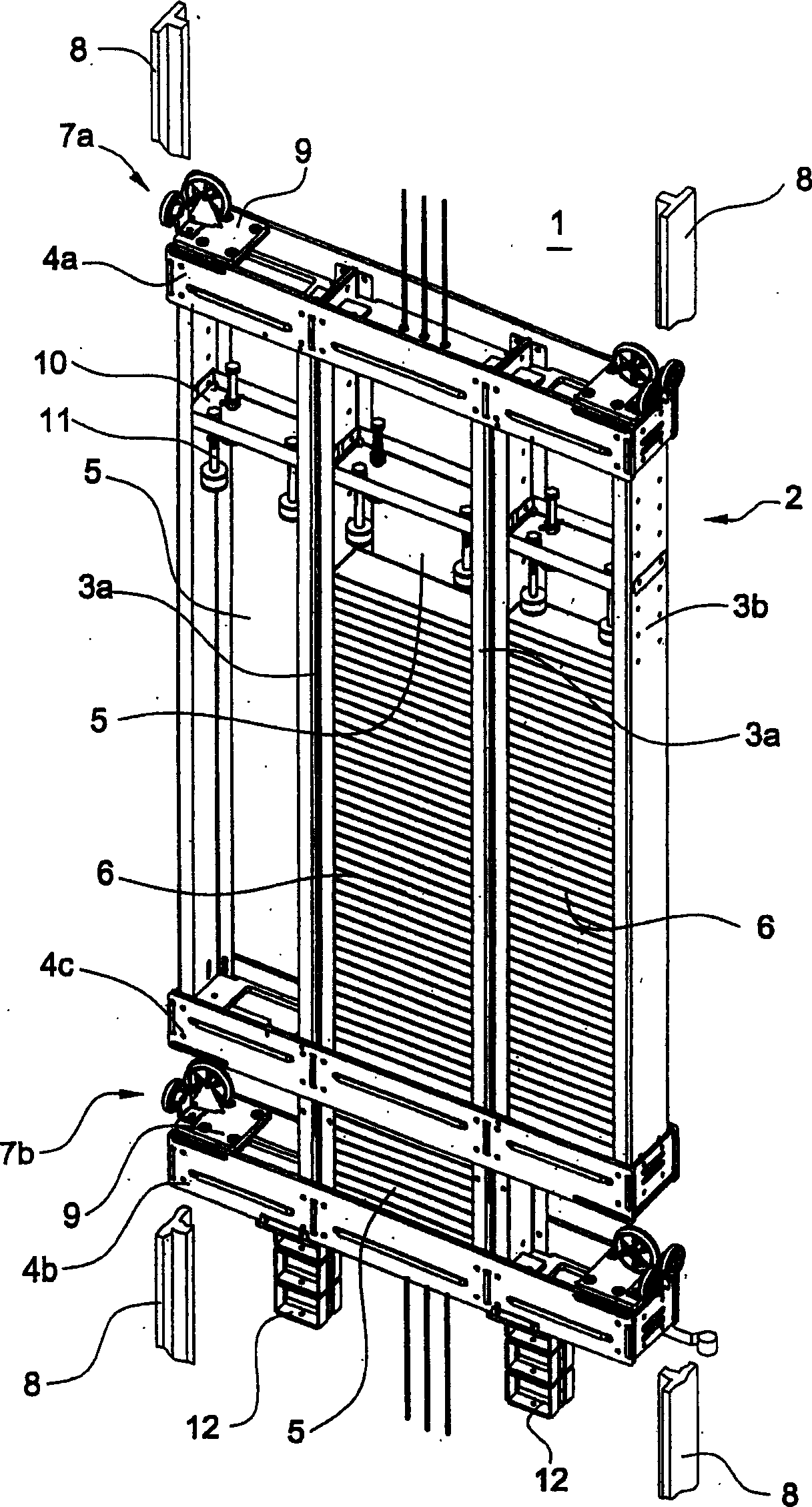

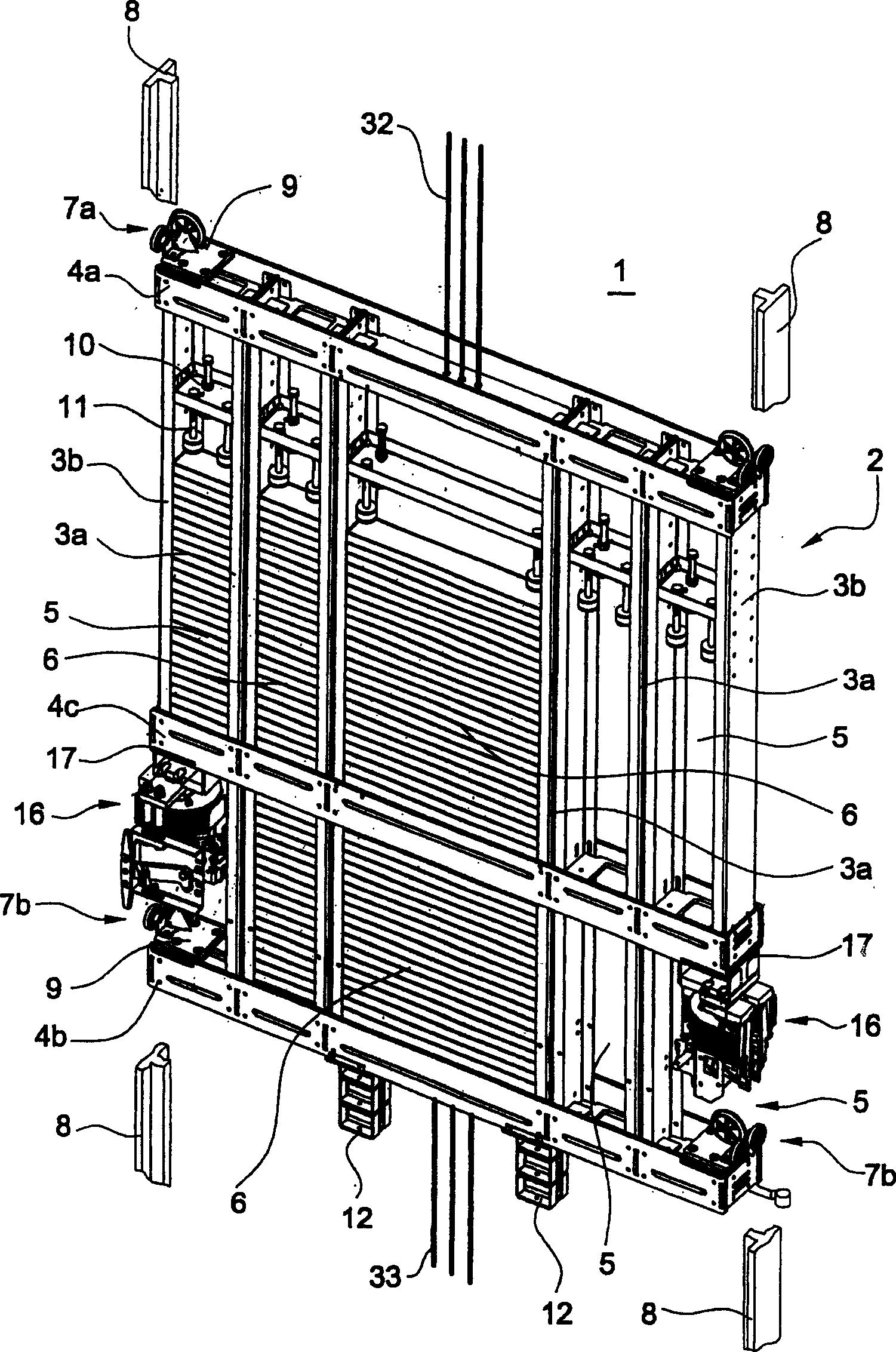

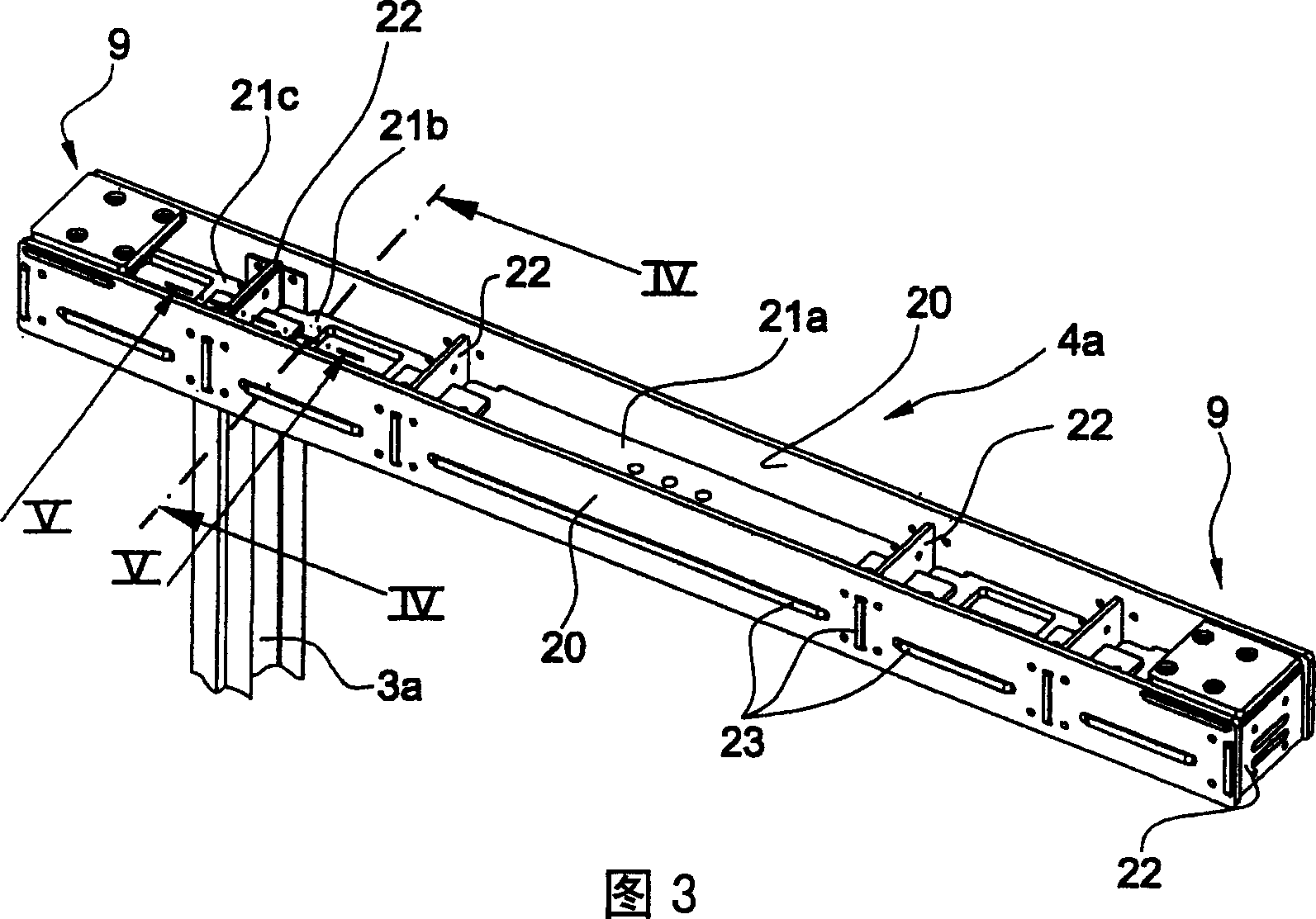

[0032] figure 1 A first embodiment of an elevator counterweight 1 according to the invention is shown, said elevator counterweight 1 having a counterweight frame 2 with four vertical beams 3a, 3b, an uppermost horizontal beam 4a, A lowermost horizontal beam 4b, and a second lowermost horizontal beam 4c. The middle vertical beams 3 a each have two U-shaped profiles arranged in pairs, while each outermost vertical beam 3 b is formed from a corresponding single U-shaped profile. The vertical beams 3 a , 3 b and the horizontal beams 4 a , 4 b , 4 c together form a grid-shaped counterweight frame with a plurality of grid areas 5 for receiving weights 6 . The horizontal beams 4a, 4b, 4c are designed such that the vertical beams 3a, 3b can penetrate said horizontal beams at predetermined scarf points, wherein the horizontal beams and the vertical beams are in each case connected together at the scarf points.

[0033] The vertical beams 3a, 3b, arranged in pairs and individually, ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com