Method for producing a wiring harness and an apparatus for connecting a terminal-connected wire

A manufacturing method and a technology of a connecting device, which are applied in the manufacturing field of harnesses, can solve the problems such as the inability to increase the utilization rate of modules and the increase of equipment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

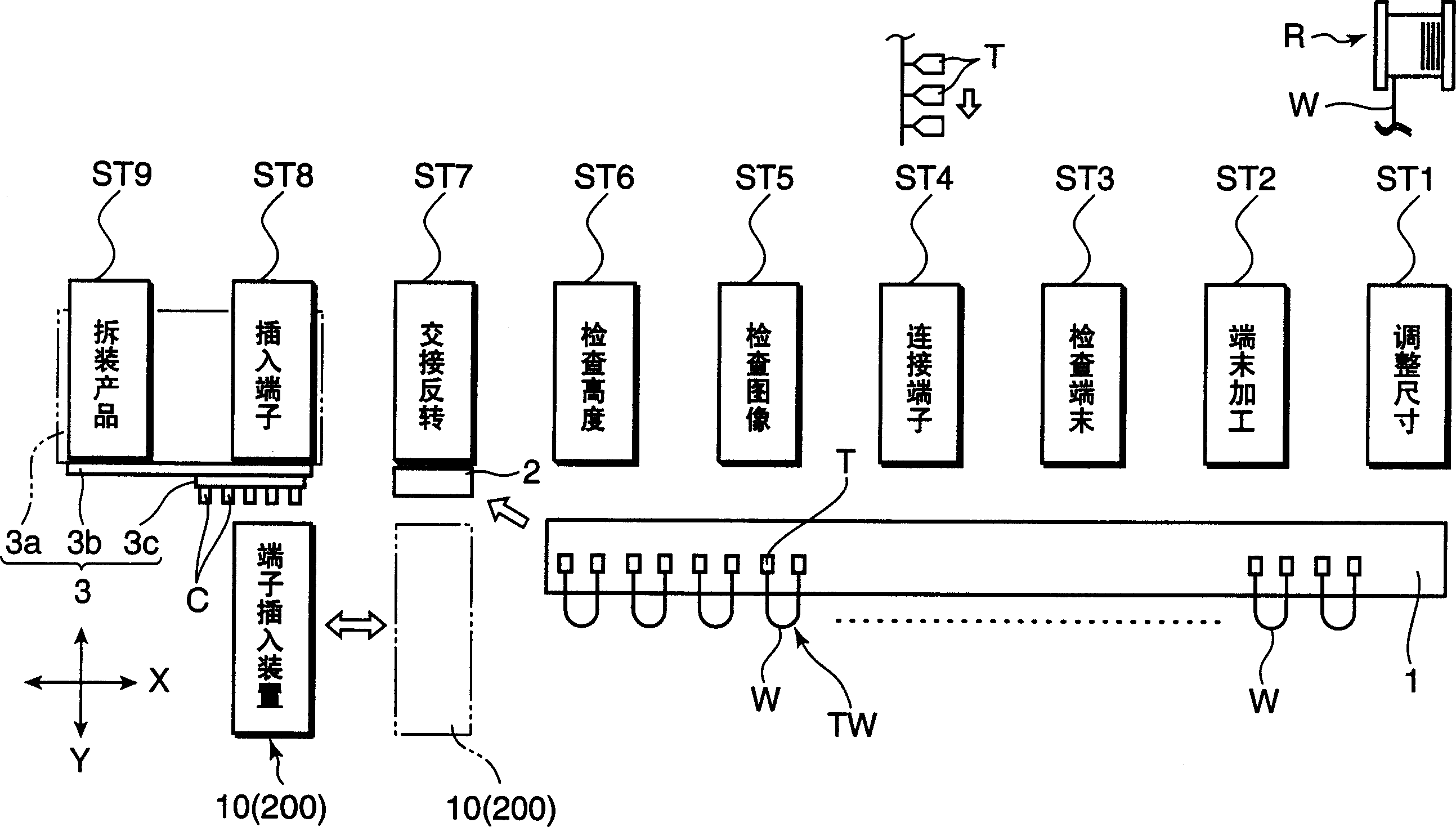

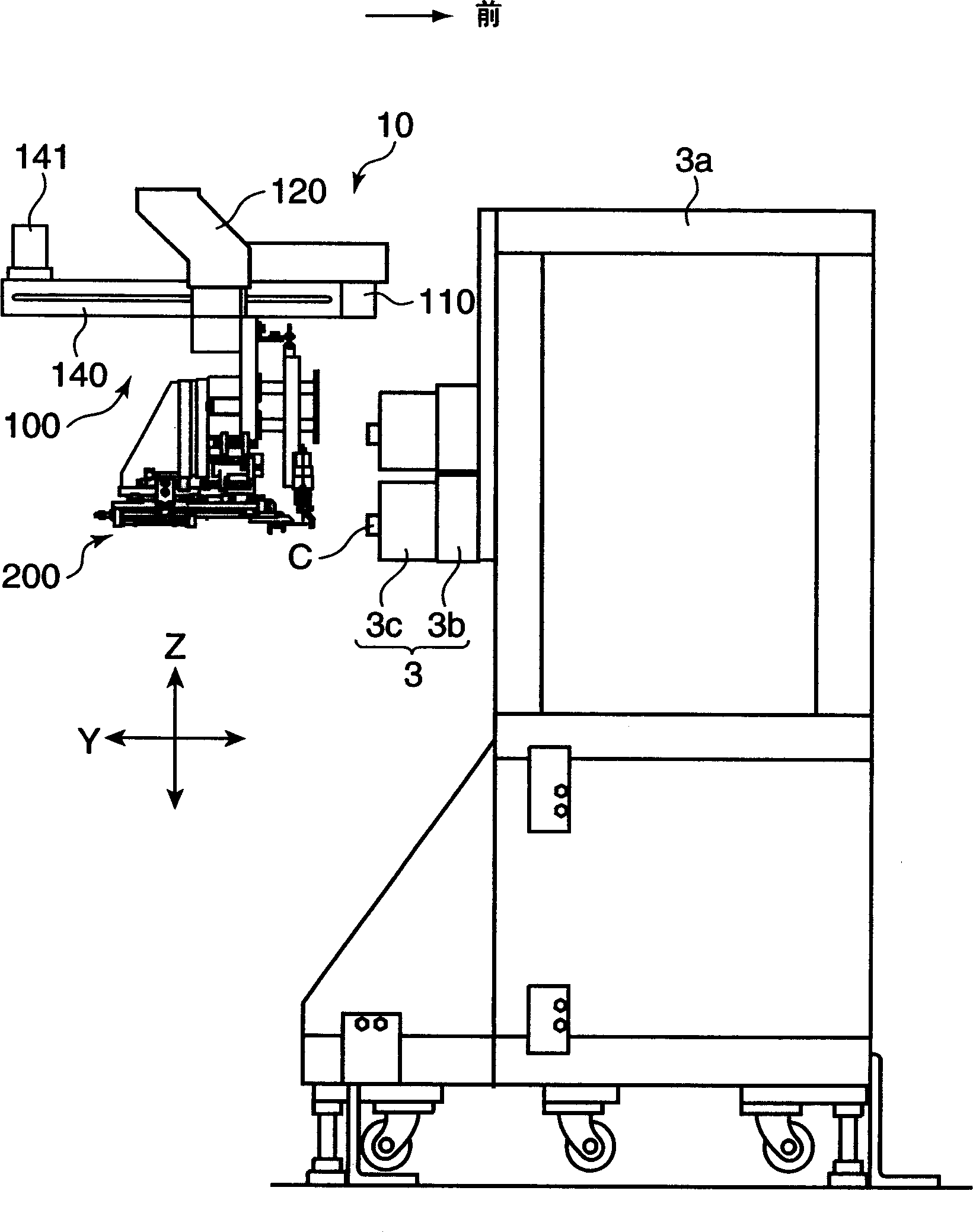

[0035] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

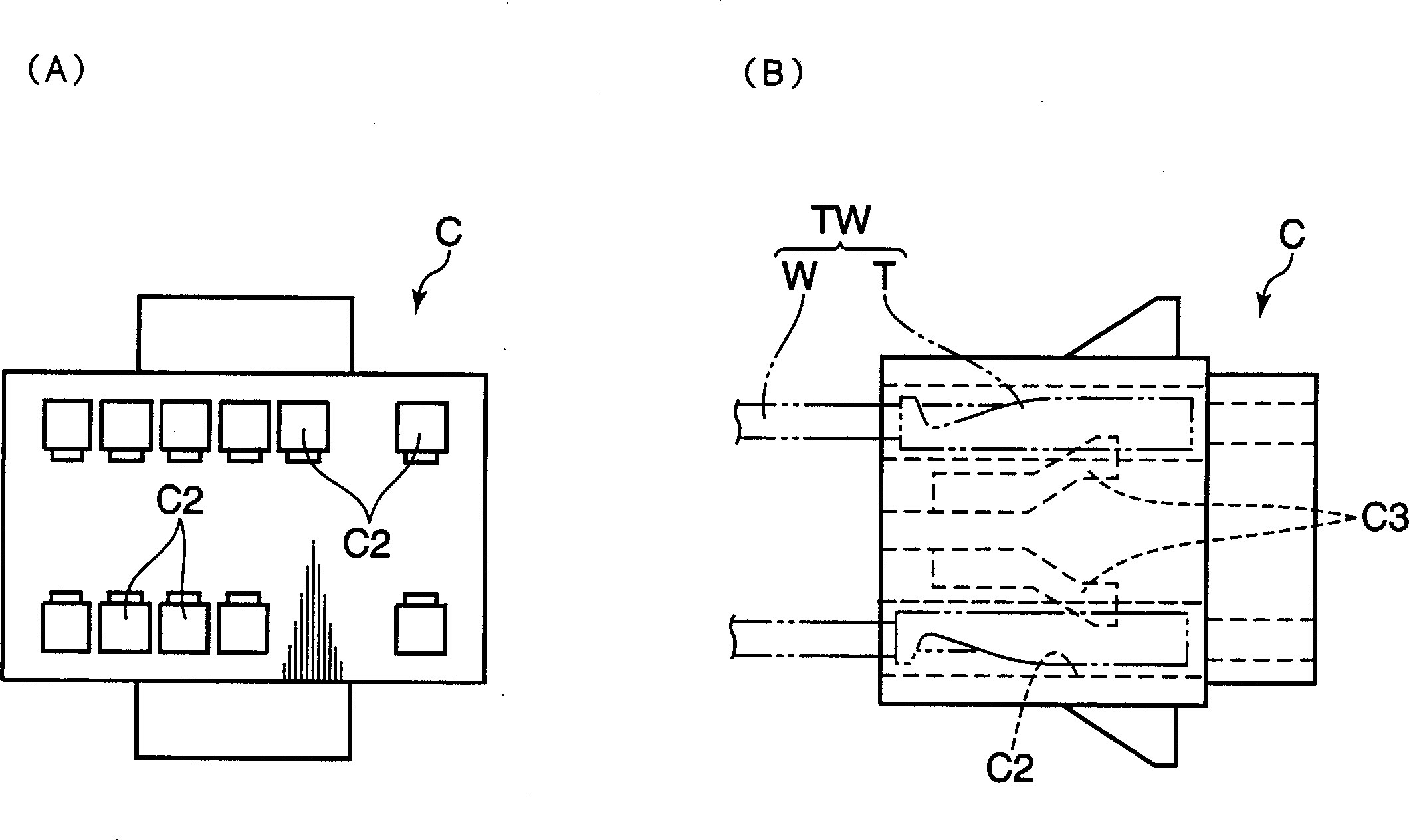

[0036] figure 1 It is a schematic external view of the connection box (Connect housing) which concerns on this embodiment, (A) is a front view, (B) is a side view.

[0037] refer to figure 1(A)(B), the connection box C in the figure, forms a plurality of holes (Cavity) C2 distributed asymmetrically on its front. The holes C2 are arranged in two rows up and down when viewed from the front, and the phases of the terminals T of the terminal wires TW are reversed at the positions of the upper row and the lower row. A cantilever-shaped locking tongue (locking tongue) C3 is provided in each hole C2. The brake reed C3 adopts a common brake method, and fits into the groove formed on the bottom surface of the terminal T, so that the terminal T is fixed in the connection box C. In the illustrated embodiment, each brake reed C3 has a free end extending upward from the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com