Tyre evenness tester

A uniformity and testing machine technology, which is applied in the direction of automobile tire testing, tire installation, tire parts, etc., can solve the problems of reduced speed, narrowed gap, and adverse effects on measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

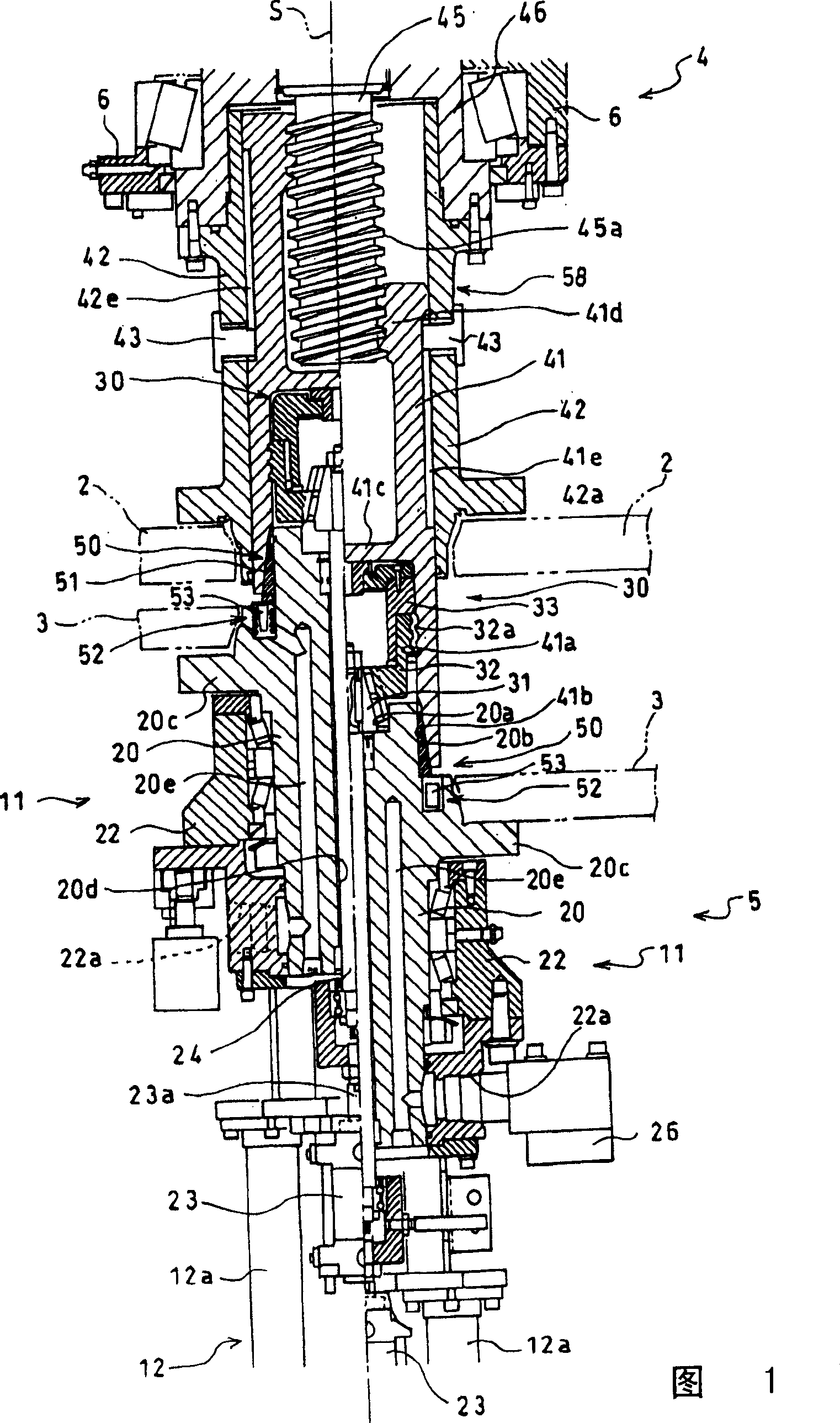

[0044] Below according to Figure 1 to Figure 8 Embodiments of the present invention will be described.

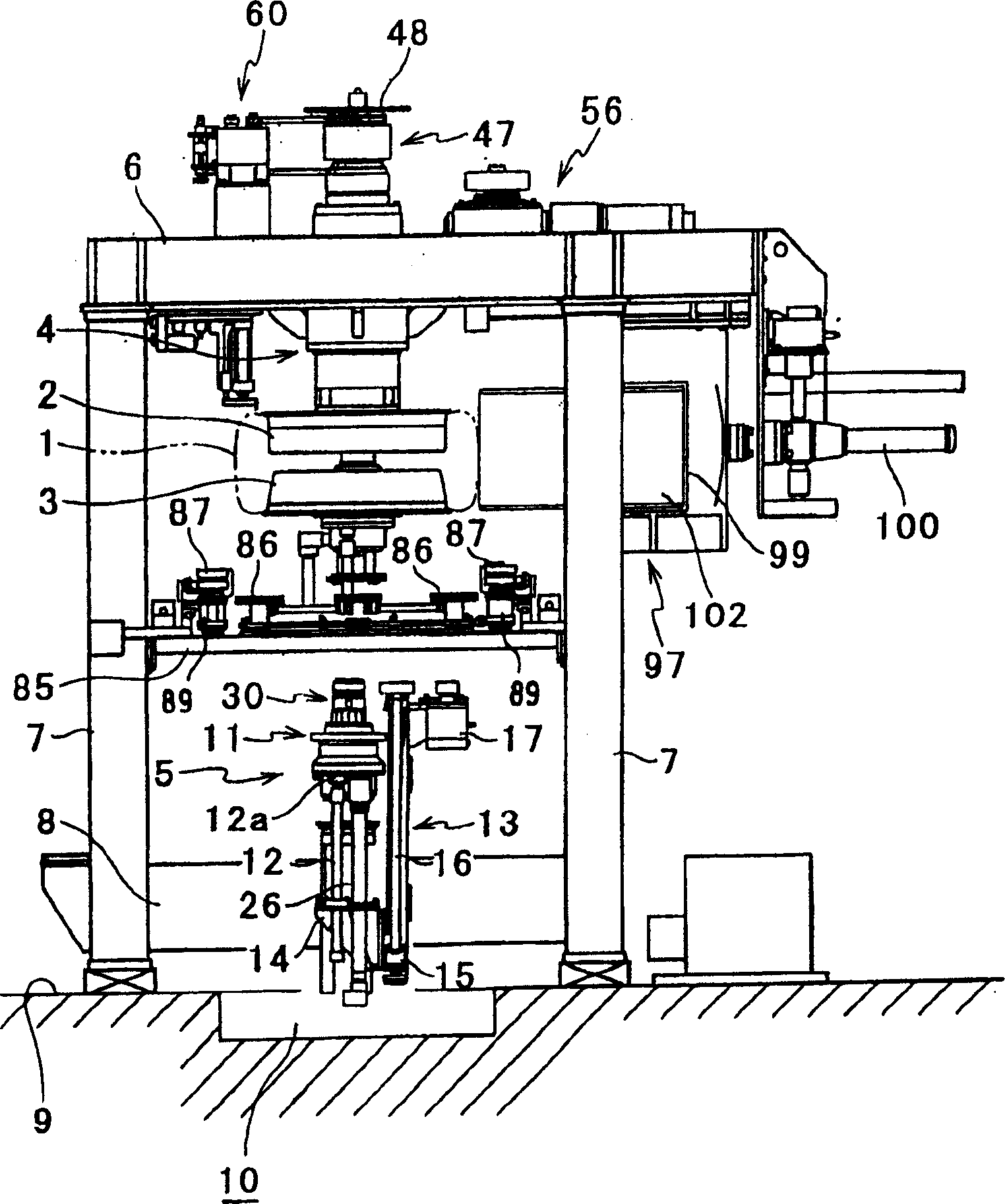

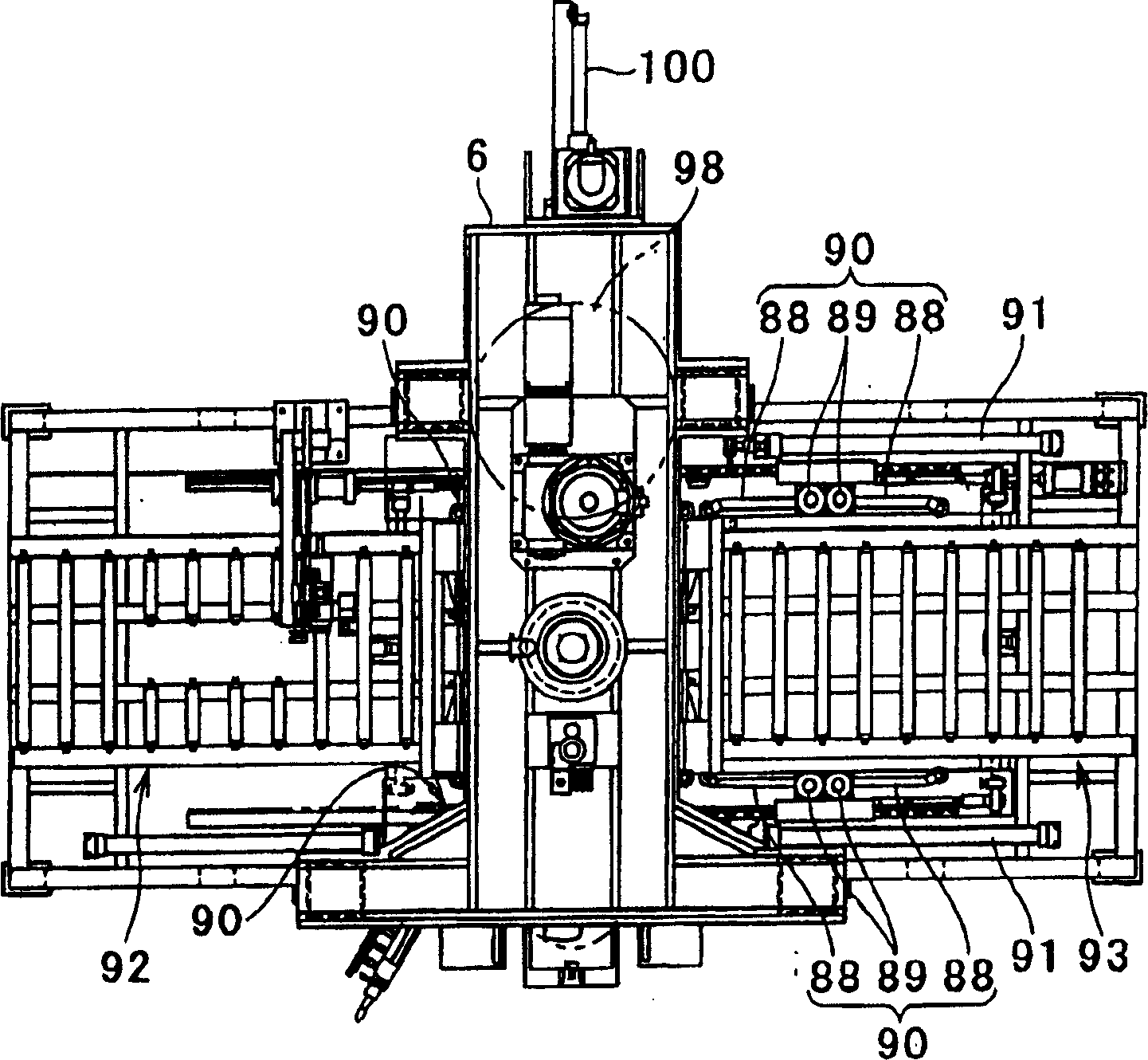

[0045] According to the tire uniformity testing machine of the present embodiment, such as figure 2 As shown, the upper rim 2 holding the upper bead portion of the tire 1 and the lower rim 3 holding the lower bead portion of the tire 1 are included. The upper rim 2 is detachably provided on the front end portion (lower end portion) of the upper spindle 4 . On the other hand, the lower rim 3 is detachably provided on the front end portion (upper end portion) of the lower spindle 5 . The two mandrels 4, 5 make the upper rim 2 and the lower rim 3 face each other, and at the same time, make the axes of the two rims 2, 3 be on the same straight line and coincide with each other.

[0046] The upper mandrel 4 and the lower mandrel 5 are respectively arranged on the top frame 6 and the bottom frame 8 . These racks 6 and 8 are supported by a plurality of racks 7 arranged vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com