Boiler smoke purifying method

A soot purification and boiler technology, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve problems such as tall chimney smoke and dust, and achieve remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

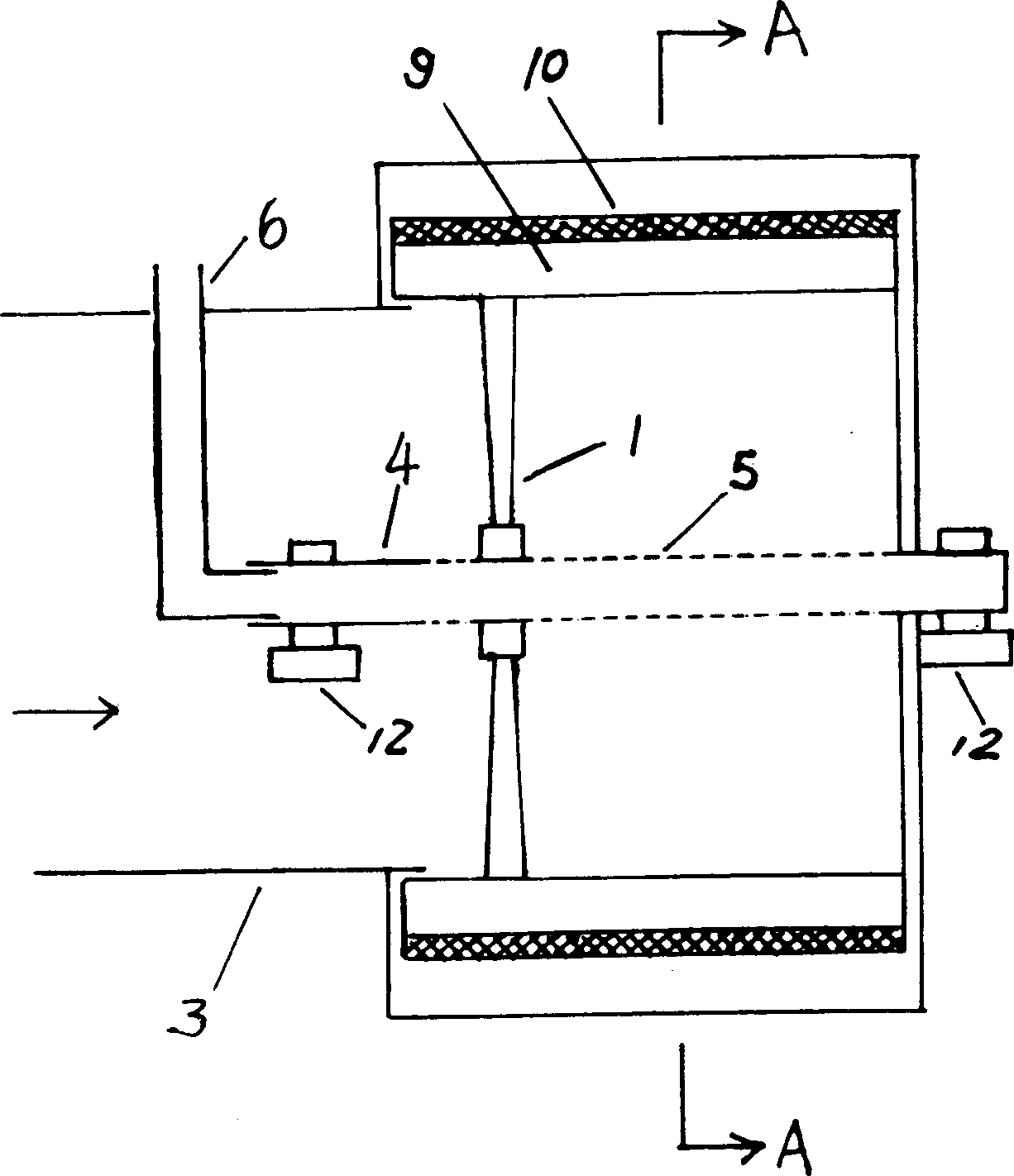

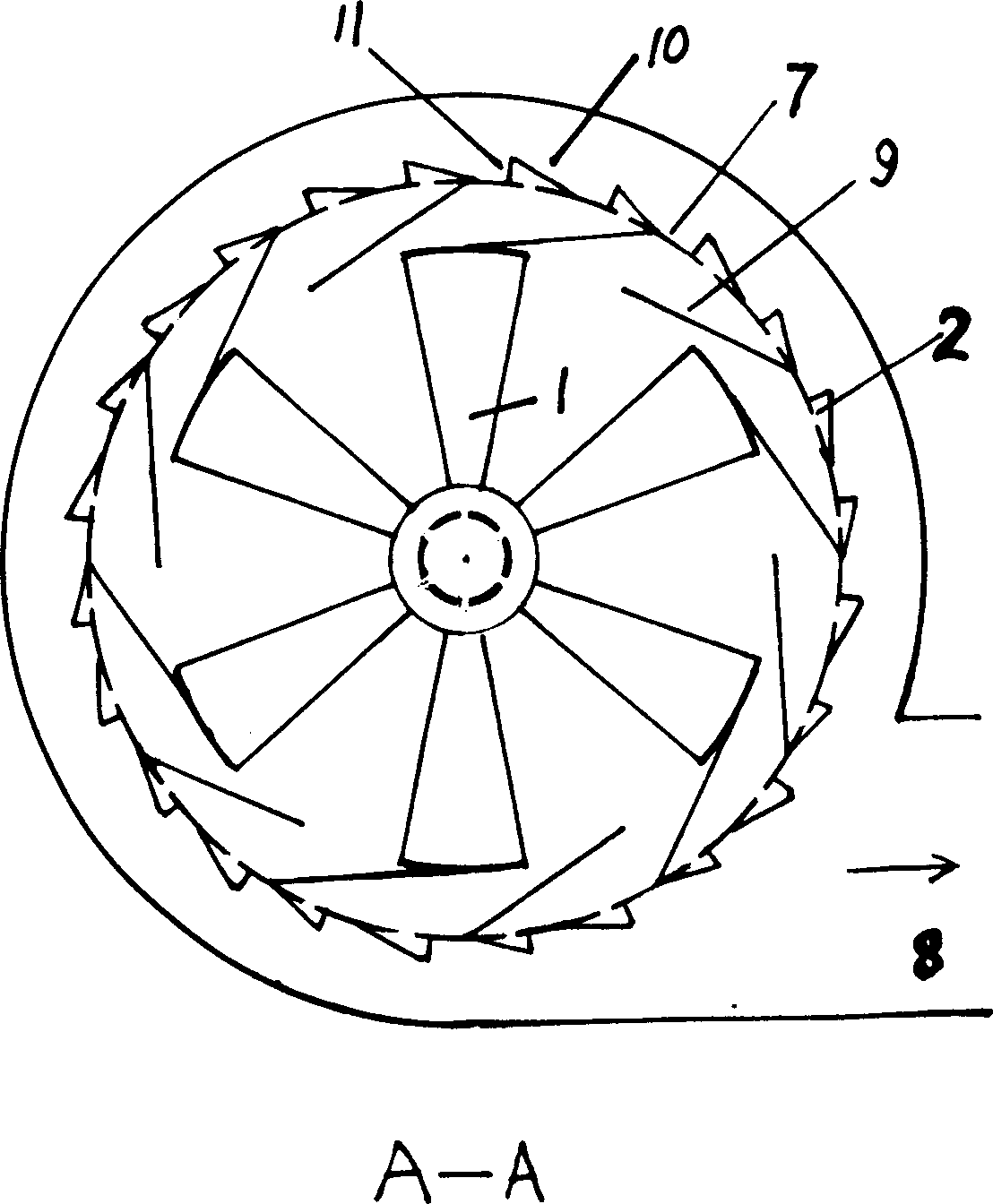

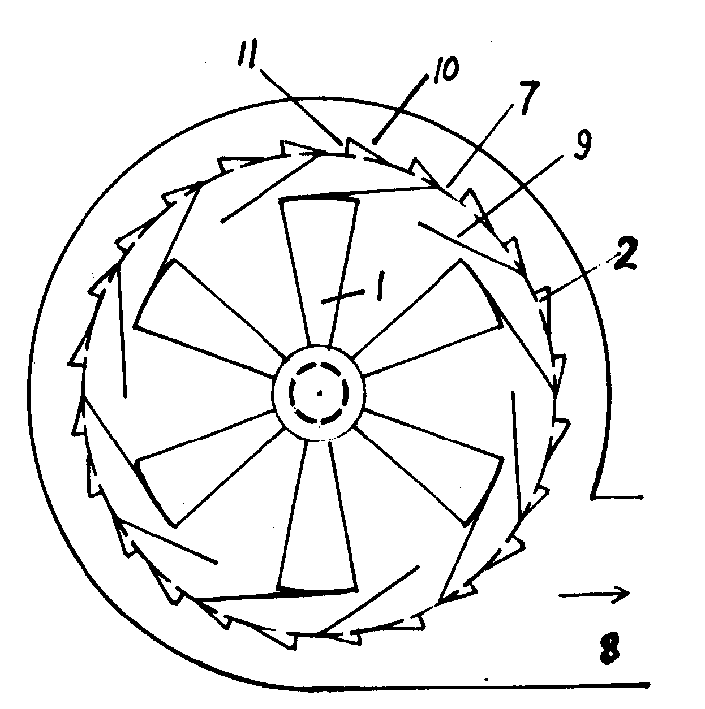

[0007] The specific embodiment of the present invention is that when the smoke is sucked into the pipeline by the rotary blade fan (1) from the horizontal pipeline (3), the water in the water inlet pipe (6) flows into the tube shaft (4), and is rotated by the rotary blade fan (1). Under the action of centrifugal force, the water is thrown out from the water outlet hole (5) on the pipe shaft, forming mist, and the smoke and dust contact with the water and mix with each other. In the angle chamber formed with the drum (7), since the drum (7) and the fan (1) rotate coaxially and in the same direction, the dust and water are squeezed in the angle chamber. Through the small holes (2) in the flue on the drum, strong mixing is produced, and then the smoke and water mist enter the air outlet screen (10) on the periphery of the drum (7). The plate (11) shields the wind, so that the rear of the windshield (11) forms a low pressure, which is beneficial to the smoke, dust and water mist t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com