Fusion splicing device and fusion splicing method

A fusion splicing equipment, fusion splicing technology, applied in the direction of instruments, optics, light guides, etc., can solve problems such as difficult to identify optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The best way to carry out the invention

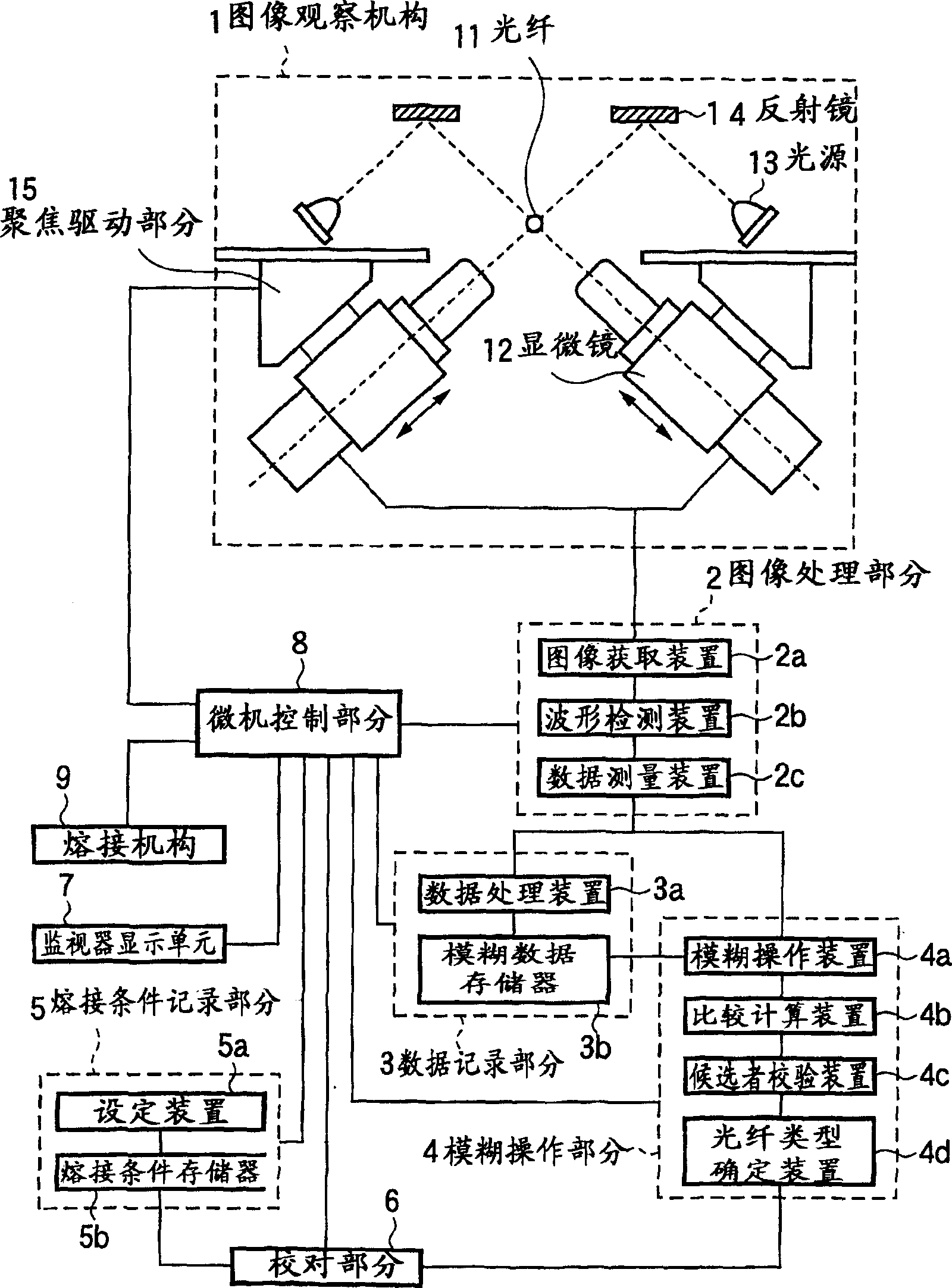

[0022] figure 1 is a block diagram for explaining an embodiment of the present invention. exist figure 1 Among them, the symbol 1 represents the image observation mechanism, the symbol 2 represents the image processing part, the symbol 3 represents the data recording part, the symbol 4 represents the fuzzy operation part, the symbol 5 represents the welding condition recording part, the symbol 6 represents the proofreading part, and the symbol 7 represents the monitor display Unit, reference numeral 8 represents the control part, reference numeral 9 represents the fusion splicing mechanism, reference numeral 11 represents the optical fiber, reference numeral 12 represents the microscope, reference numeral 13 represents the light source, reference numeral 14 represents the reflector, and reference numeral 15 represents the focus driving part.

[0023] The image observation mechanism 1 uses a microscope 12 with a CCD camera arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com