Method and device for separating 1, 2, 3-trimethylbenzene

A technology for the separation of trimethylbenzene and its separation method, which is applied in the field of separation method and device of trimethylbenzene, and can solve the problems of high energy consumption, large energy consumption, and large reflux ratio of the production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

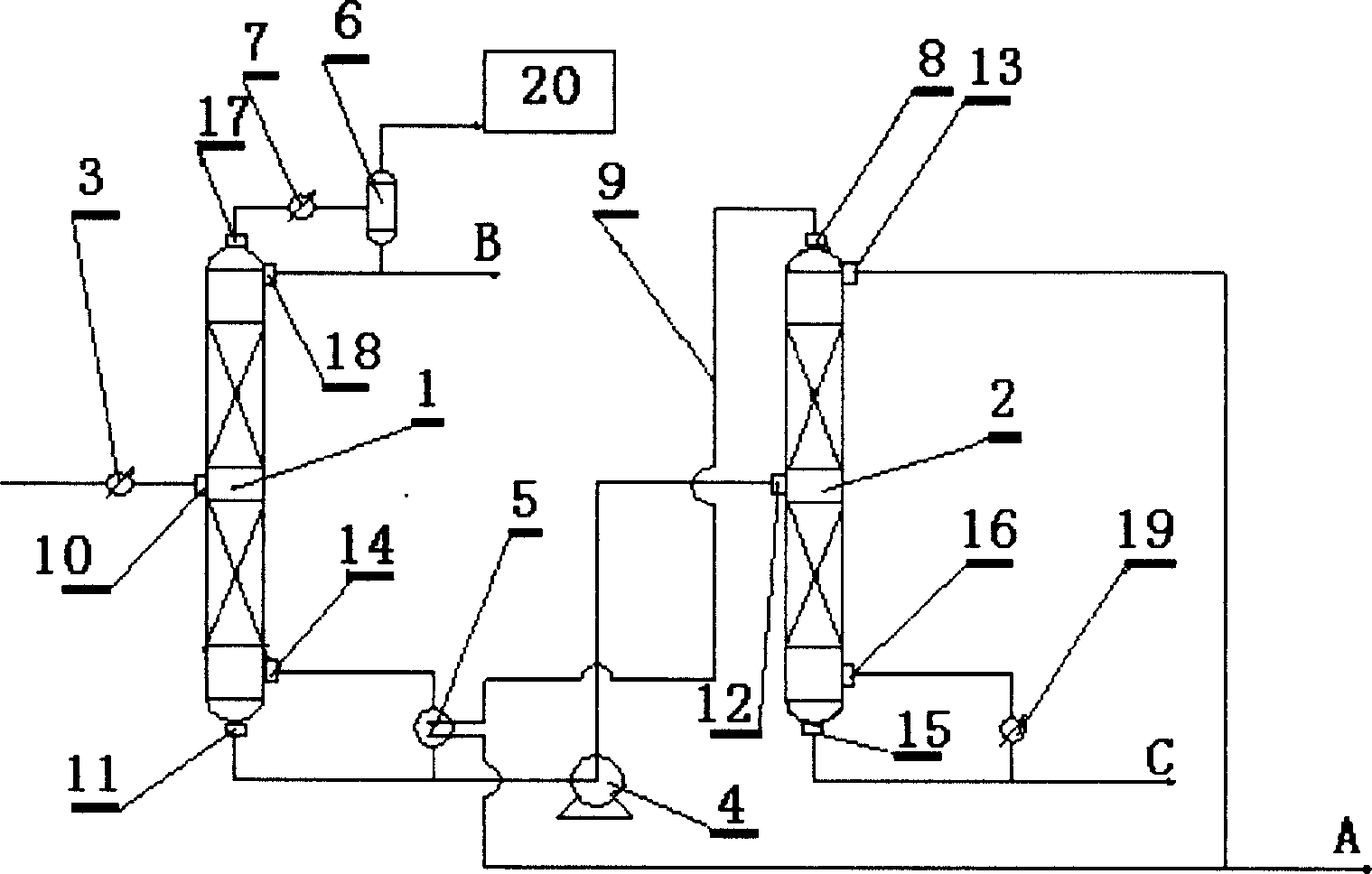

[0008] Embodiment 1: A kind of method and device for separating trimethylbenzene, comprising light removal tower 1, product tower 2, preheater 3, feed pump 4, condenser 7, etc., raw material enters light removal tower 1 through preheater 3 , the top tank 6 of the light removal tower 1 is connected to the vacuum system 20, so that the inside of the light removal tower 1 is negative pressure,

[0009] The device of the present invention is mainly composed of a light removal tower 1, a product tower 2, a preheater 3, a feed pump 4, a condenser 7, a reflux tank 6, a vacuum system 20, and a bottom reboiler 5. One end of the condenser 7 is connected to the gas phase outlet 17 , and the other end is connected to the reflux tank 6 , and the reflux tank 6 is connected to the vacuum system 20 . The light removal tower 1 is divided into two parts, the upper part is the rectification section, and the lower part is the stripping section; each part is composed of several trays or packing of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com