Servo-assisted butterfly valve provided with a compression spring to stabilise the limp-home positions

A technology of butterfly valve and elastic body, which is applied in the direction of lifting valve, valve device, electrical control, etc., and can solve the problem of changing the inelastic in-situ air flow value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

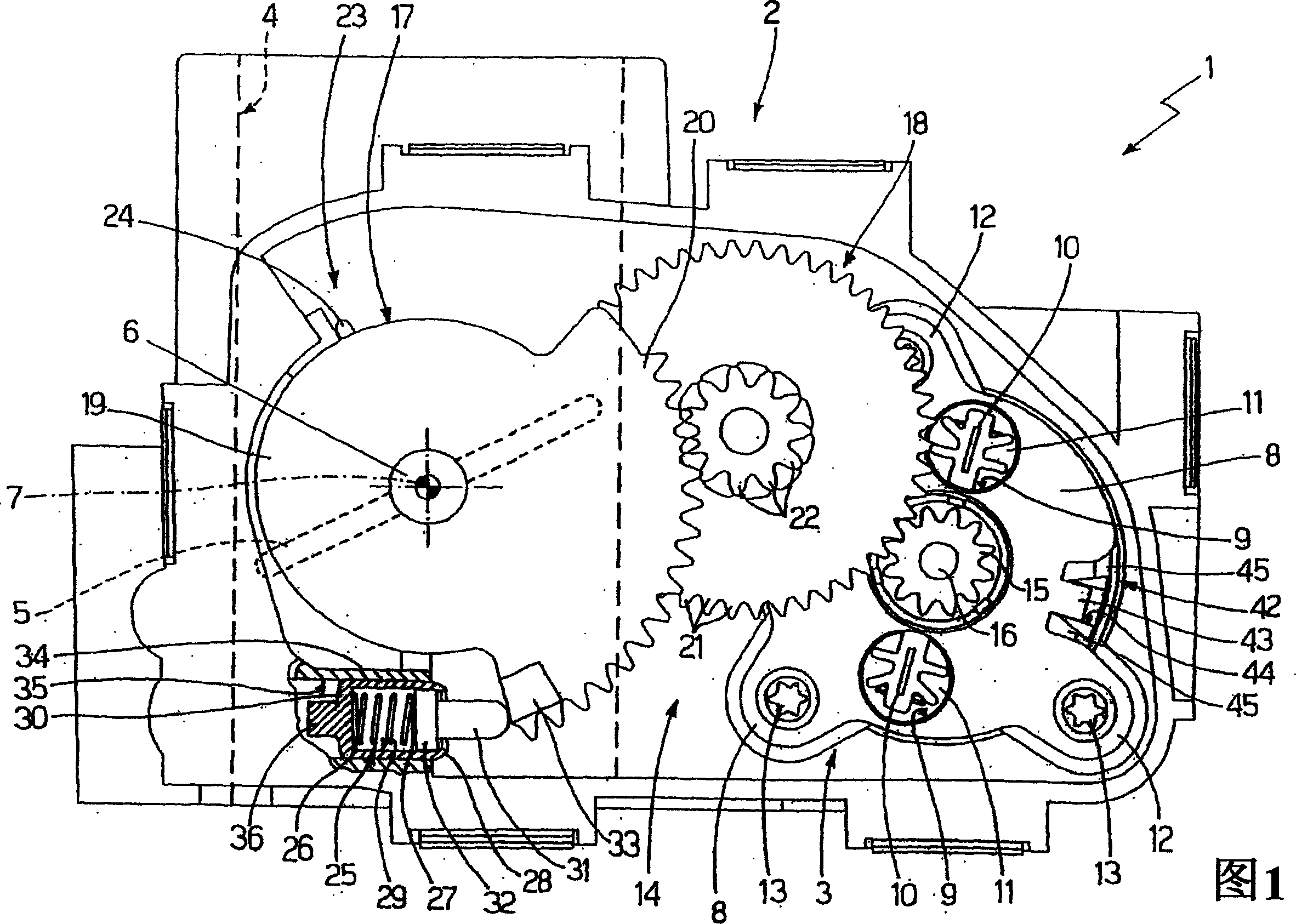

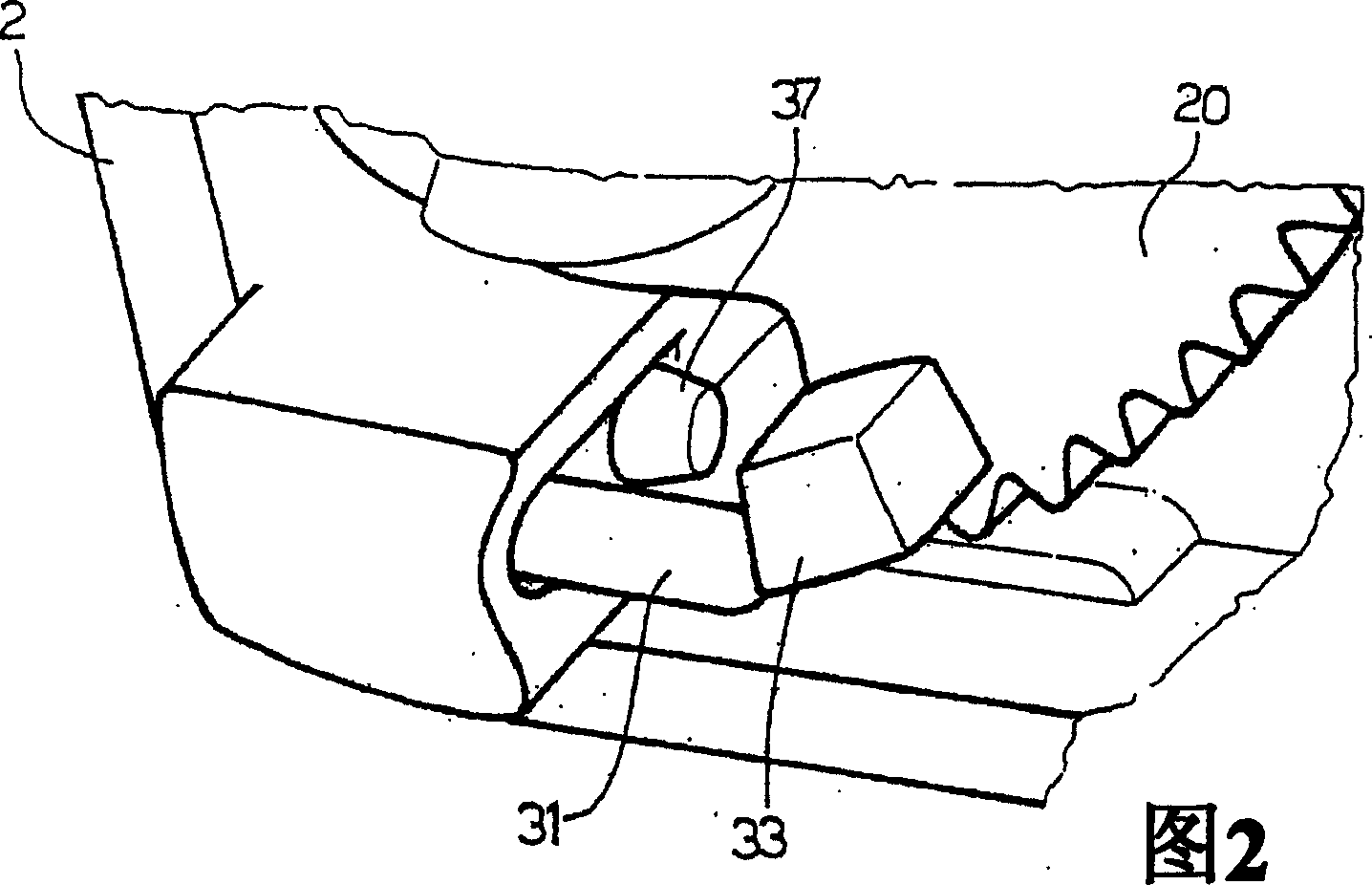

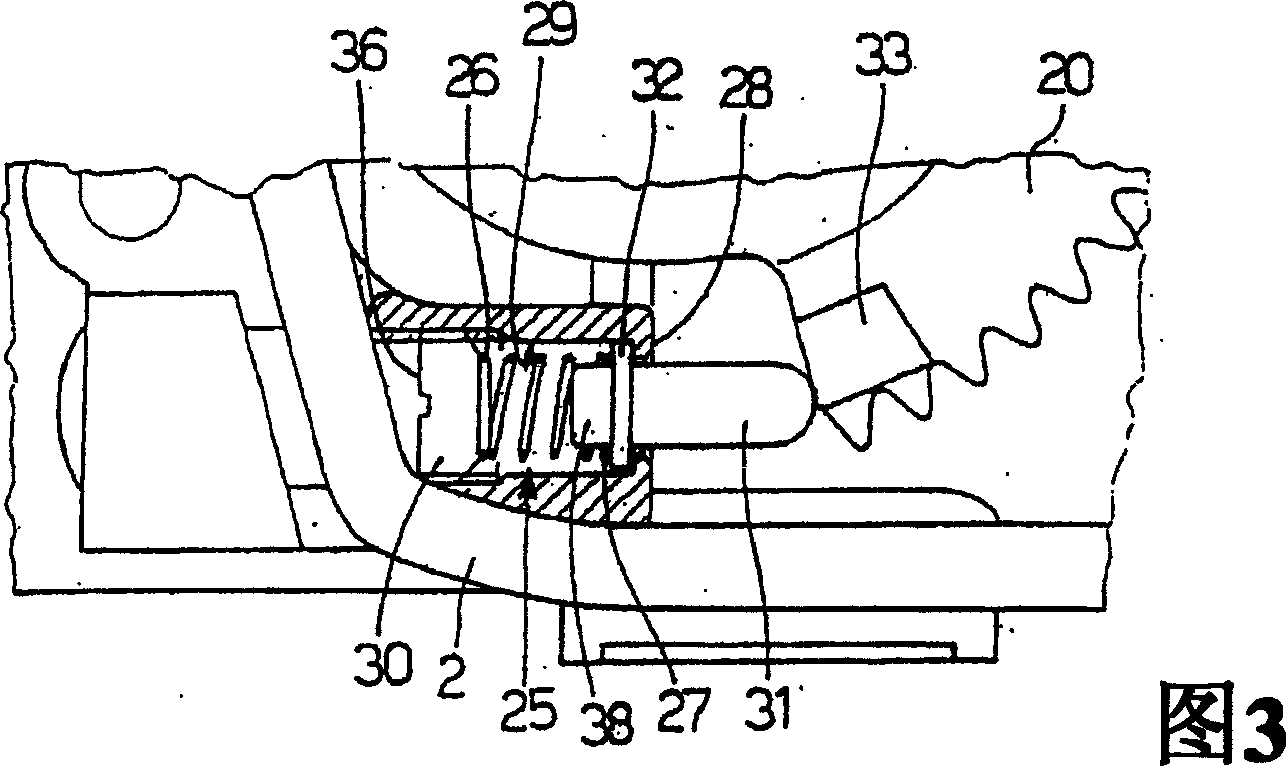

[0016] In Figure 1, a servo-assisted butterfly valve for an internal combustion engine is indicated generally by 1; the butterfly valve 1 comprises a valve body 2 housing an electric actuator 3, a cylindrical valve seat 4 (in the figure Schematically represented by a dotted line) and a butterfly body 5 that engages the valve seat 4 and moves between the maximum open position and the closed position of the valve seat 4 under the action of the electric actuator 3 (schematically represented by a dotted line in the figure ). The butterfly body 5 is key-fitted on a metal shaft 6 mounted on the valve body 2 for rotation about a longitudinal axis 7 under the action of an electric actuator 3 in the aforementioned maximum open position and the aforementioned closed position of the valve seat 4 Move the butterfly body 5 between.

[0017] The electric actuator 3 consists of a cylinder which is inserted into a corresponding cylindrical seat on the valve body 2 and held in place in the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com