Construction method for polyvinyl plastic pipeline long distance deep water crossing river

A polyethylene plastic and construction method technology, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of unsuitable polyethylene plastic pipe laying and restrictions on the application of polyethylene plastic pipes, etc., to achieve Reliable assurance of project quality and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

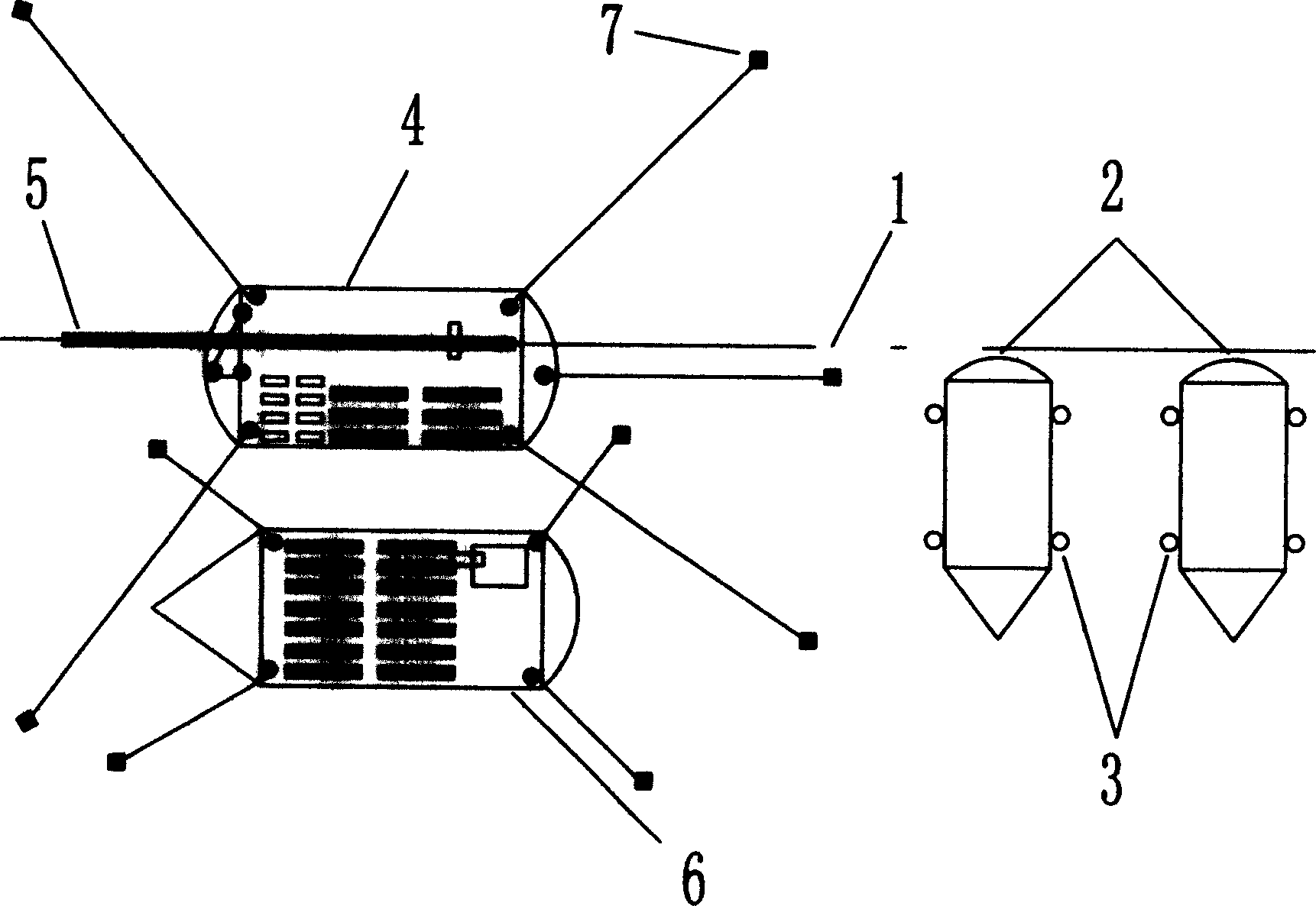

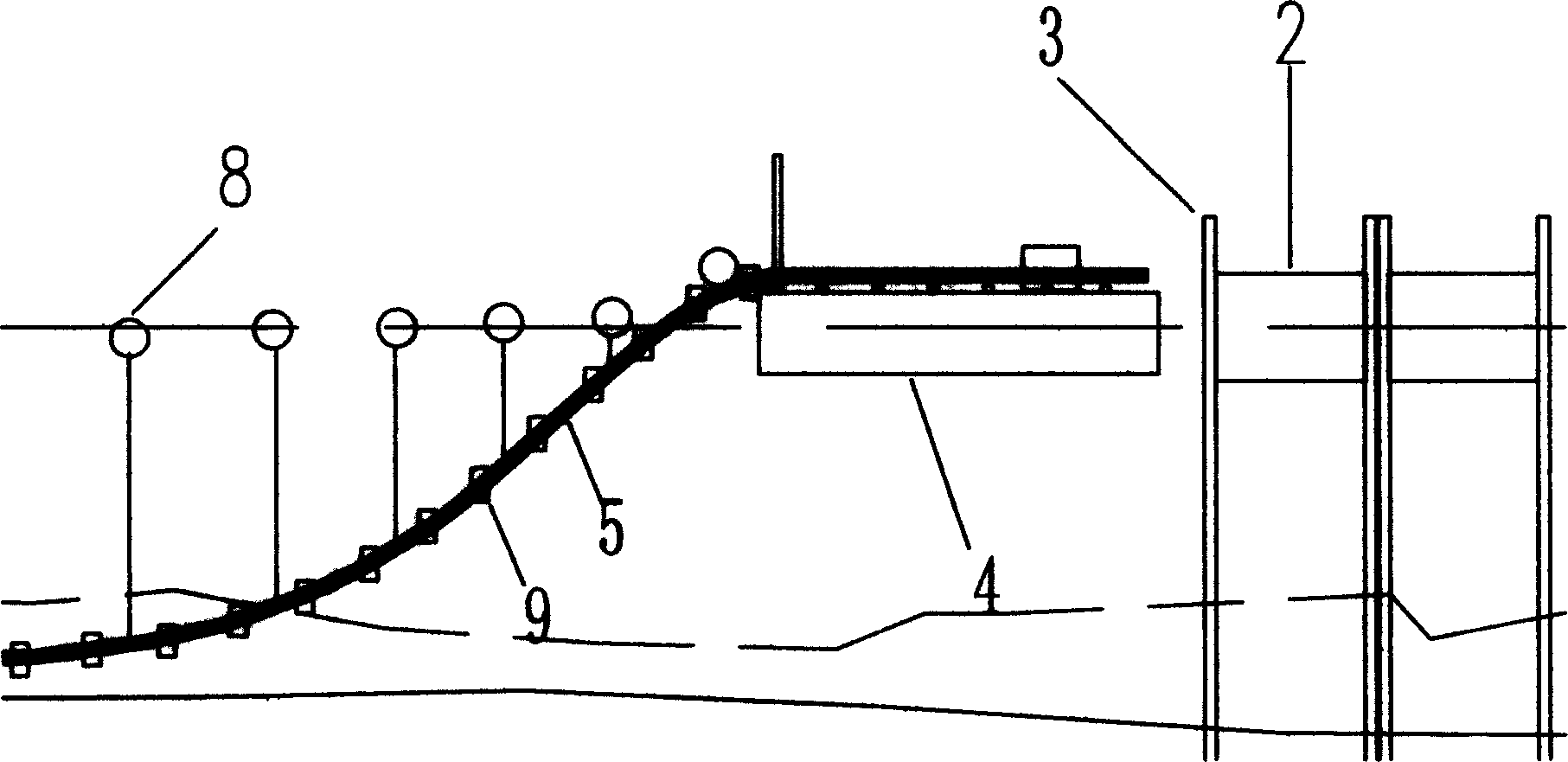

[0026] Below in conjunction with accompanying drawing and embodiment further illustrate construction method of the present invention.

[0027] Embodiment The construction site is located in the tidal section, with strong wind, strong waves, fast flow, and changeable terrain. The characteristics of the river course are: the width is 1200 meters, the lowest elevation of the riverbed is -9.11m, the average high tide elevation is 4.81m, and the average low tide is 1.01 m, the average tidal range of ebb and flow is 3.8 meters, the maximum water depth is 14 meters, the speed of high tide is 0.8 m / s, and the speed of ebb tide is 1.3 m / s. The geology is mainly medium sand. The pipeline to be laid is a polyethylene plastic water supply pipeline with a diameter of 630mm.

[0028] The construction method and steps of this embodiment are as follows.

[0029] a. According to the design requirements, first use GPS positioning system, total station and depth sounder to recheck and measure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com