Batch treatment apparatus and wafer treatment method

A processing device and wafer processing technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of narrow tolerance margin, large electrical differences, defective products, etc., to reduce the generation of defective products , the effect of reducing the electrical difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

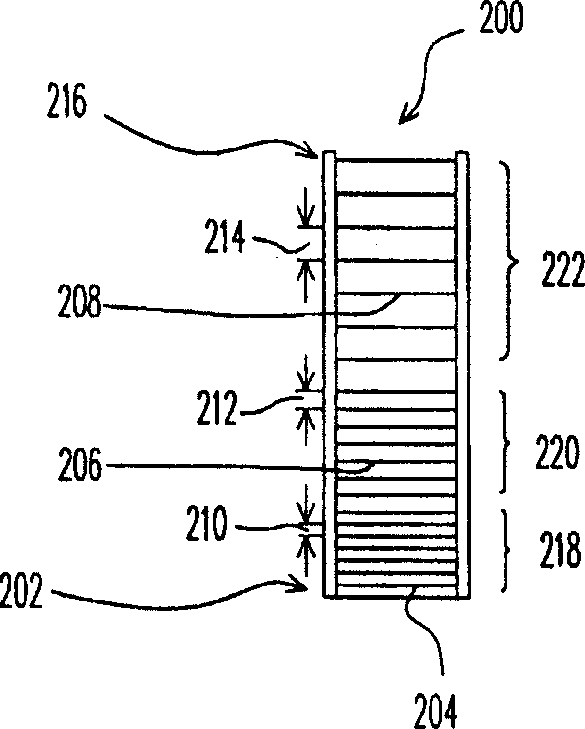

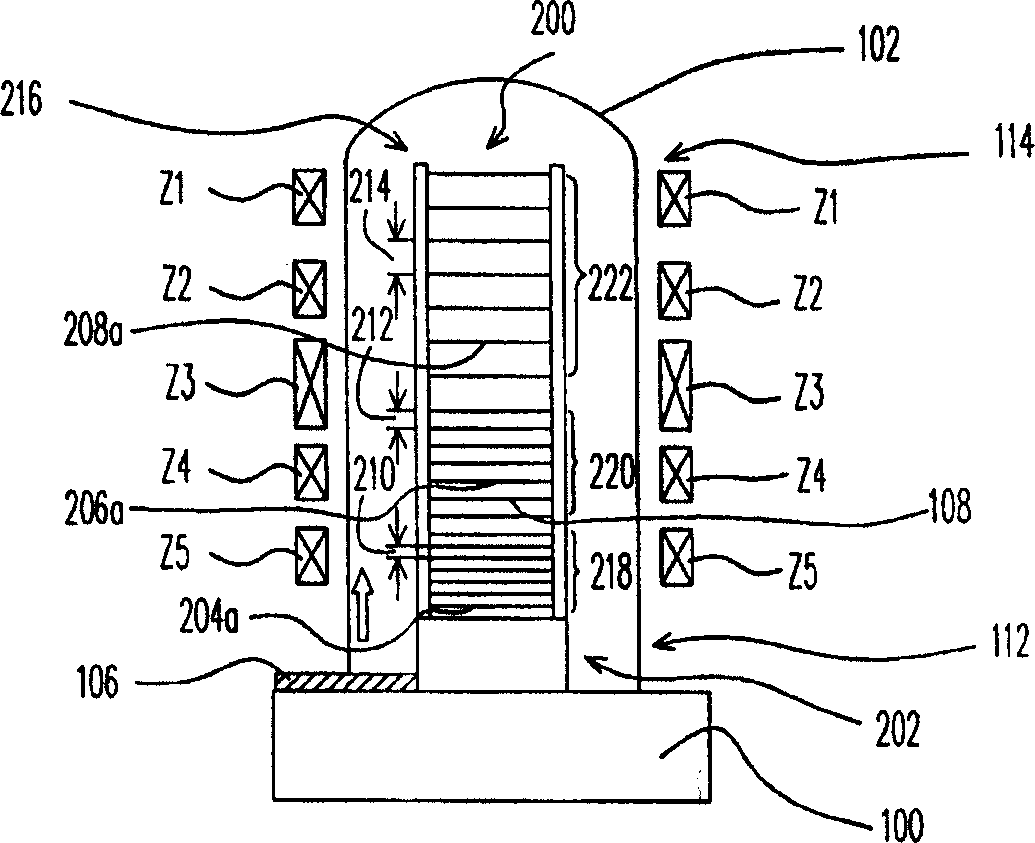

[0033] figure 2 is a schematic cross-sectional view of a wafer boat showing a preferred embodiment of the present invention. Please refer to figure 2 The wafer boat 200 includes a plurality of wafer slots (wafer slots) 204, 206, and 208, wherein the wafer slots 204, 206, and 208 make the wafers (not shown) disposed therein parallel to each other with the surfaces of the wafers, And in the wafer boat 200 , the pitch of the wafer slots gradually increases from the end portion 202 toward the end portion 216 along the direction perpendicular to the wafer surface.

[0034] In this embodiment, the wafer boat 200 is divided into a first portion 218 , a second portion 220 and a third portion 222 from the end portion 202 to the end portion 216 . Wherein the first part 218 has a plurality of wafer slots 204 with the same spacing between the wafer slots 204, and the second part 220 has a plurality of wafer slots 206 with the same spacing between the wafer slots 206, The third part 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap