State monitoring system and method for injection molding machine

A state monitoring and monitoring system technology, applied in the field of injection molding machine state monitoring system and monitoring, can solve problems such as monitoring errors, product yield decline, and manpower monitoring cannot be monitored from time to time, so as to reduce unnecessary losses, The effect of reducing the production of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0051] Example one

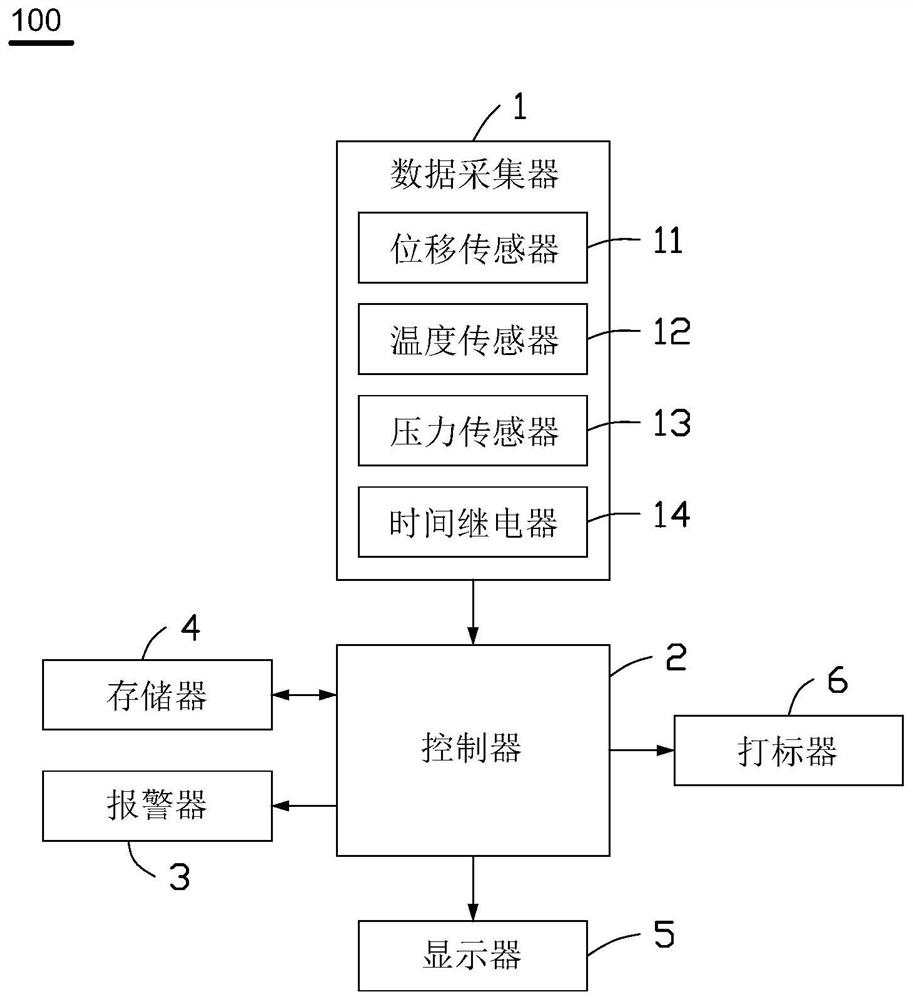

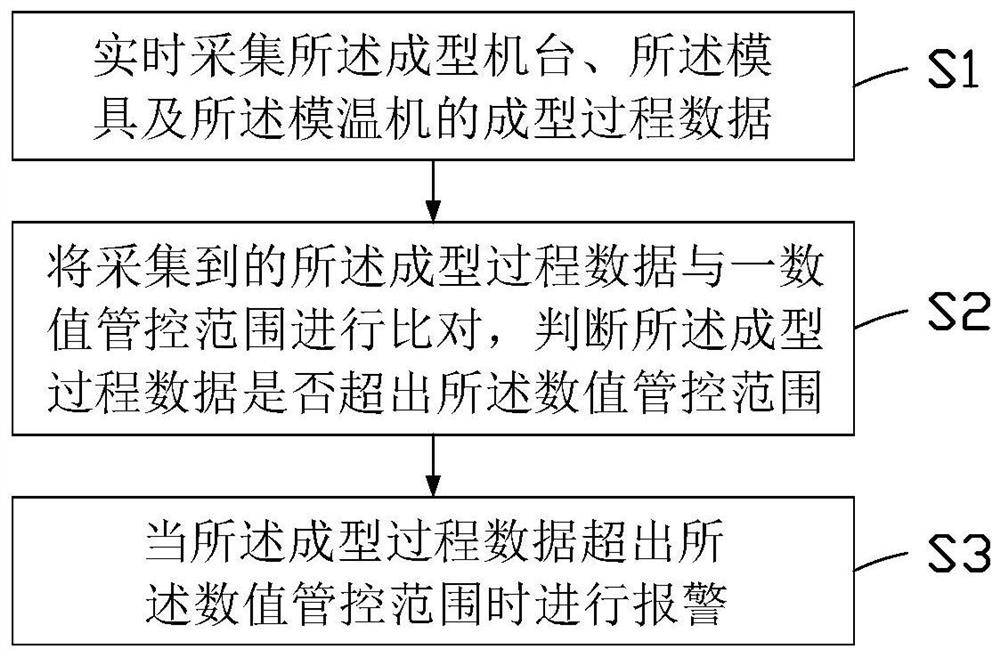

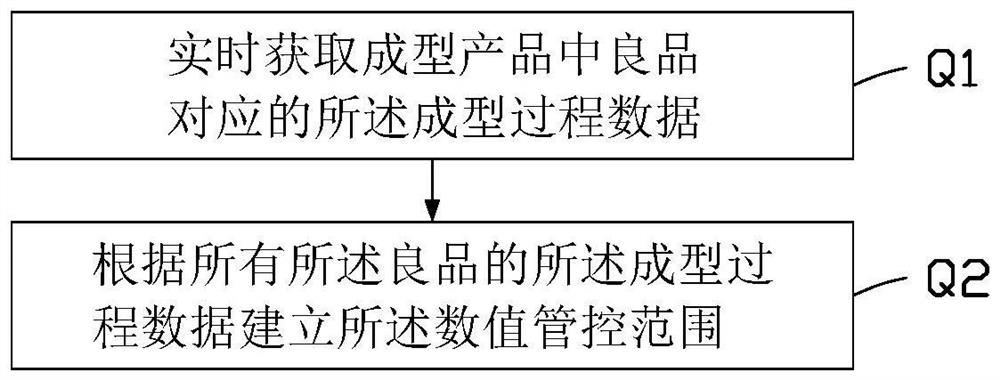

[0052] figure 1 Is the injection molding machine condition monitoring system according to a first embodiment of the principles of the present invention, FIG. 100.

[0053] In the present embodiment, the injection molding machine condition monitoring system 100 may be applied to molding apparatus, the molding apparatus for the injection molding apparatus, comprising a molding machine, mold, and mold temperature.

[0054] like figure 1 Shown, the injection molding machine condition monitoring system 100 comprises: a data acquisition, alarm controller 2 and 3, the data collector 1 and the alarm device 3 are connected to the communication controller 2 and the .

[0055] The data collector 1 is provided in the molding machine, the mold and the mold temperature needs to collect location data, and the molding machine, the mold and the mold temperature communication connection with the data collected in the molding process molding machine, the mold temperature and th...

Example Embodiment

[0086] Example 2

[0087] See Figure 4As shown, the difference in the state monitoring system of the second embodiment provided by the present invention, the second embodiment and the first embodiment is, and the data collector 8 also includes a camera 7, the camera 7 The image used to collect the molded product, and the controller 2 is further configured to accept the image transmitted by the camera 7, and compare the image with a preset good image, determined whether the forming product is good. The parameters of the specific judgment include whether the appearance is flawed, whether the size meets the standard, and the like. It should be noted that in the range of the spirit or basic features of the present invention, each of the specific scheme suitable for use in the first embodiment can also be applied to the second embodiment, which will be used to save space and avoid repetition. Will not let go later. In the present embodiment, the camera 7 is employed to cooperate with t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap