Punching machine

The technology of a punching machine and a drilling device, which is applied in the field of punching machines, can solve problems such as time-consuming and labor-intensive, and the relative position cannot be guaranteed, so as to achieve the effects of improving efficiency, accurate relative position, and reducing the generation of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

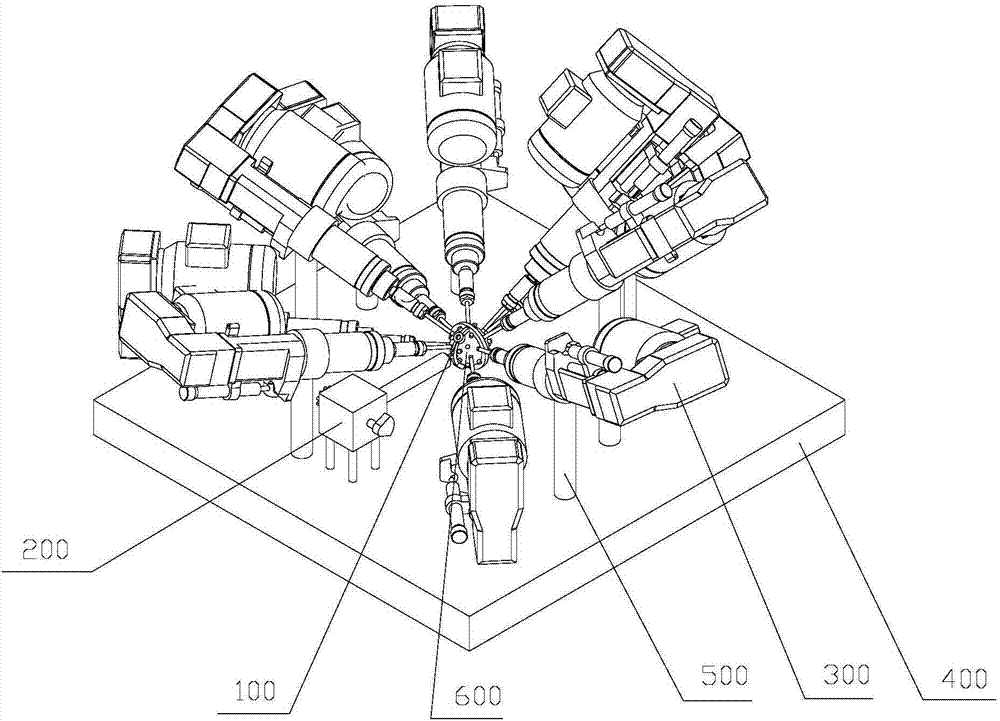

[0026] figure 1 It is a structural schematic diagram of the punching machine of the present invention.

[0027] Such as figure 1 As shown, the punching machine includes a punching tool 100 , an indexer 200 , a drilling device 300 and a worktable 400 , and the punching tooling 100 and the indexer 200 are respectively fixed on the worktable 400 .

[0028] The punching tool 100 is used for clamping the pickle ball 600, the punching tool 100 is connected with the indexer 200, and the indexer 200 drives the punching tool 100 to rotate, that is, the relative position of the pickle ball 600 and the drilling device 300 is adjusted so that the drilling device 300 can Drill the pickle ball 600 all around. For example, there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com