Hot upsetting die with guiding function

A hot heading and mold technology, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problem that it is difficult to ensure the position of the inner shape of the head, which affects the efficiency of hot heading, and products Unstable quality and other problems, to achieve the effect of shortening the time of mold adjustment and trial mold, improving the pass rate and product quality of hot heading and heading, and improving the efficiency of hot heading processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation, structure, features and effects of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

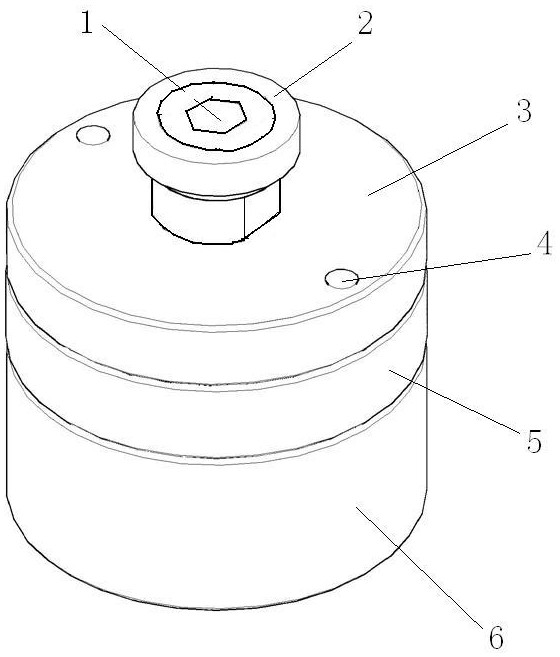

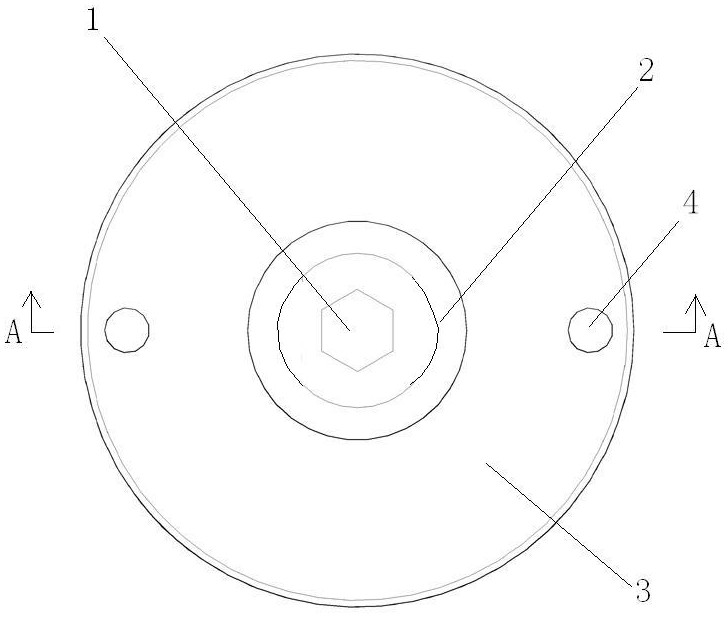

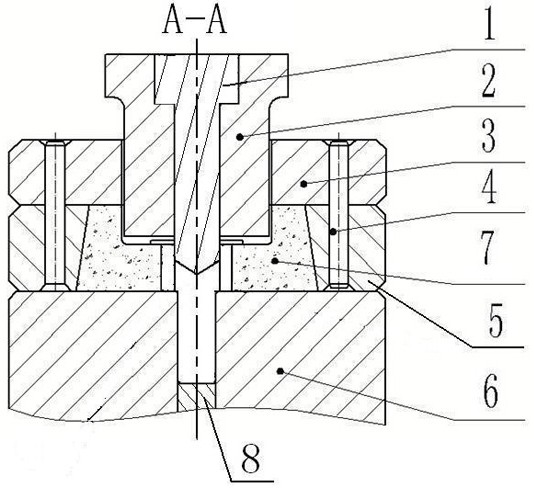

[0025] A hot upsetting mold with a guide of the present invention is characterized in that the hot upsetting male mold 1 is covered with a male mold guide sleeve 2, the male mold guide sleeve 2 passes through the die guide sleeve 3 and is inserted into the hot upsetting die 7, and the heat The outer surface of the upsetting die 7 is covered with a hot upsetting die set 5, the die guide sleeve 3 is connected with the hot upsetting die set 5 through the positioning pin 4, and the hot upsetting die set 5 and the hot upsetting die 7 are installed with a die pad 6 , Insert the ejector rod 8 below the mold pad 6 .

[0026] The lower end of the hot heading male die 1 is hexagonal, and the lower end is tapered.

[0027] The hot heading male mold 1 and the male mold guide sleeve 2 can mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com