PCB fastener

A technology of circuit boards and fixing frames, which is applied in the direction of identification devices, electrical components, and structural parts of electrical equipment, etc., can solve problems such as easy to generate errors and cannot provide horizontal pinching and tightening effects, and achieve tight joints and good uniformity display quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention utilizes the L-shaped fixing frame connected to the circuit board by the U-shaped tenon clip to provide a tightening effect that the circuit board is clamped horizontally to the center line, so as to achieve good and uniform display quality of the light-emitting diode display.

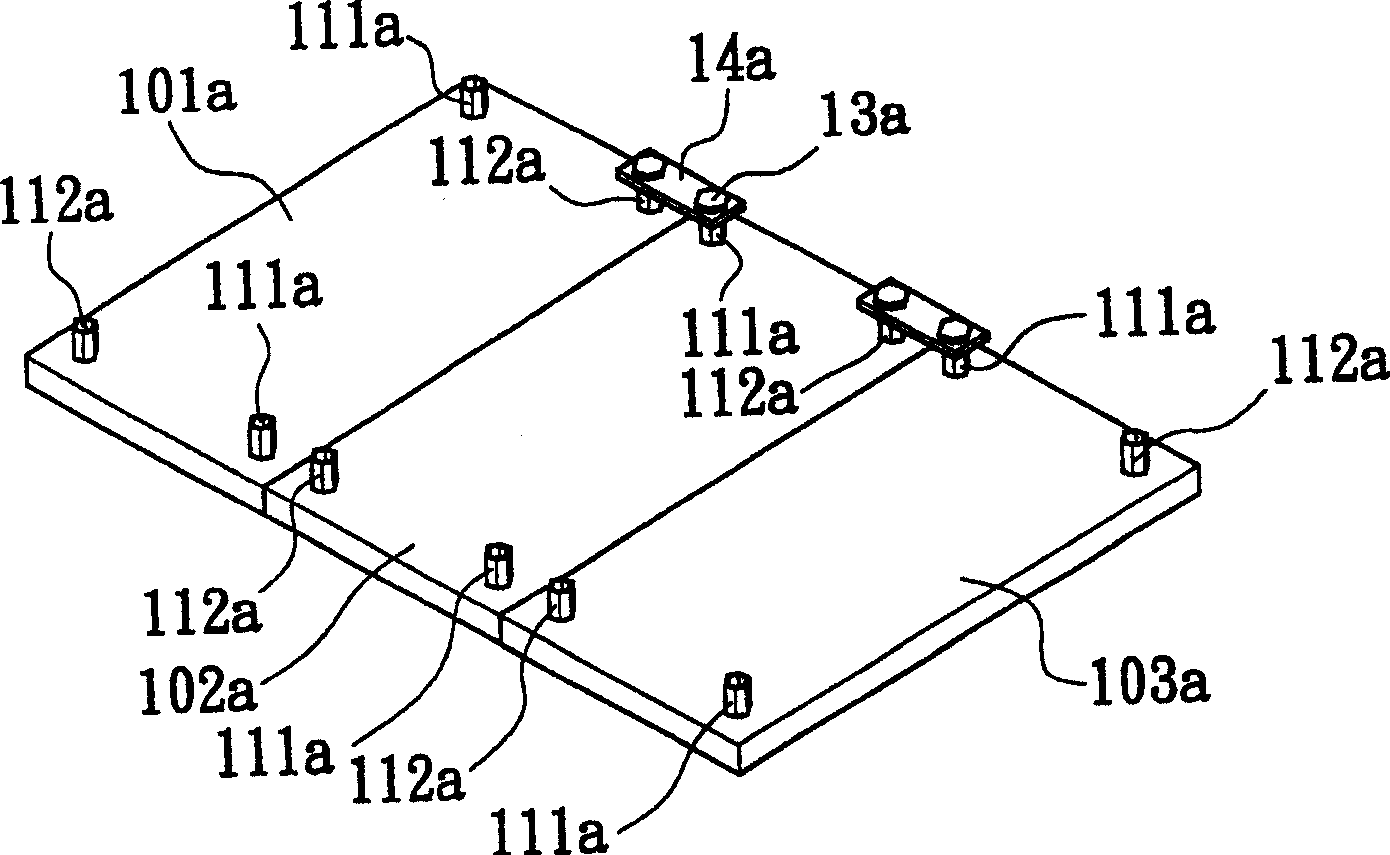

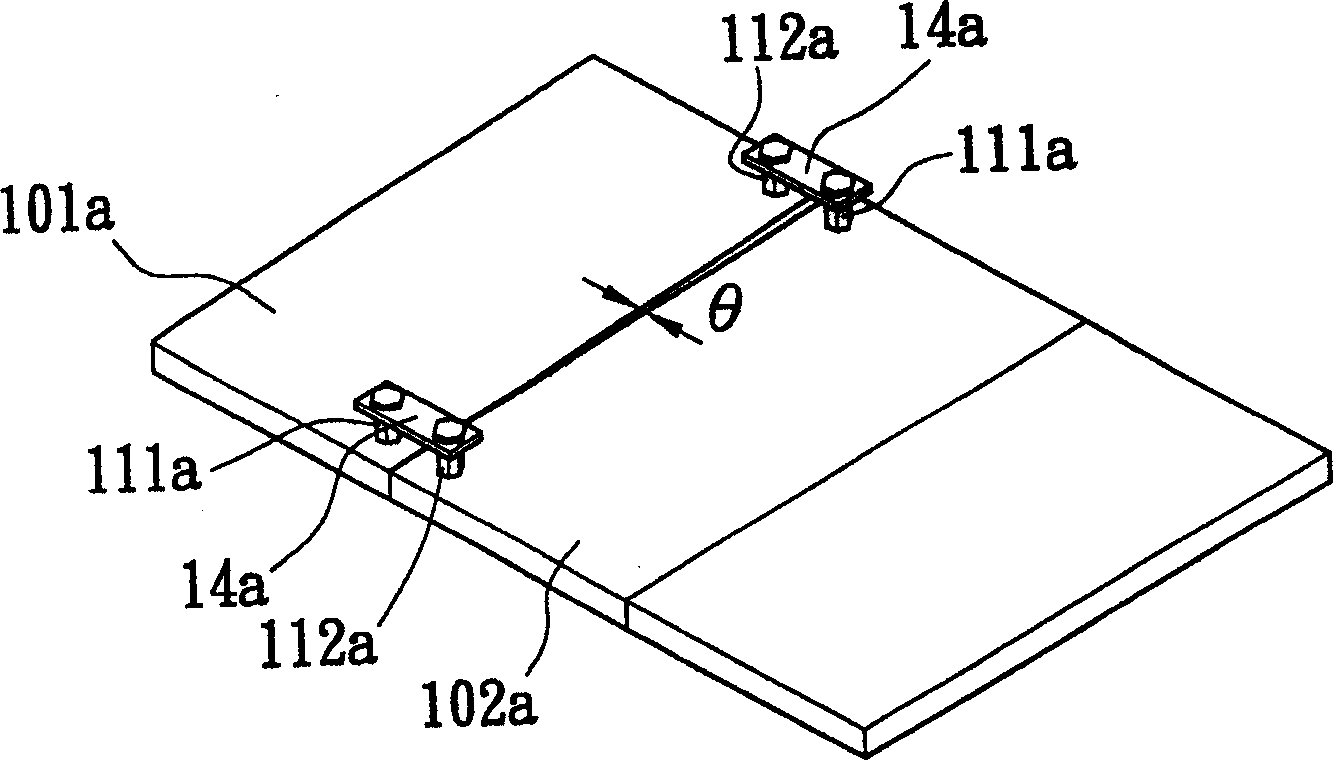

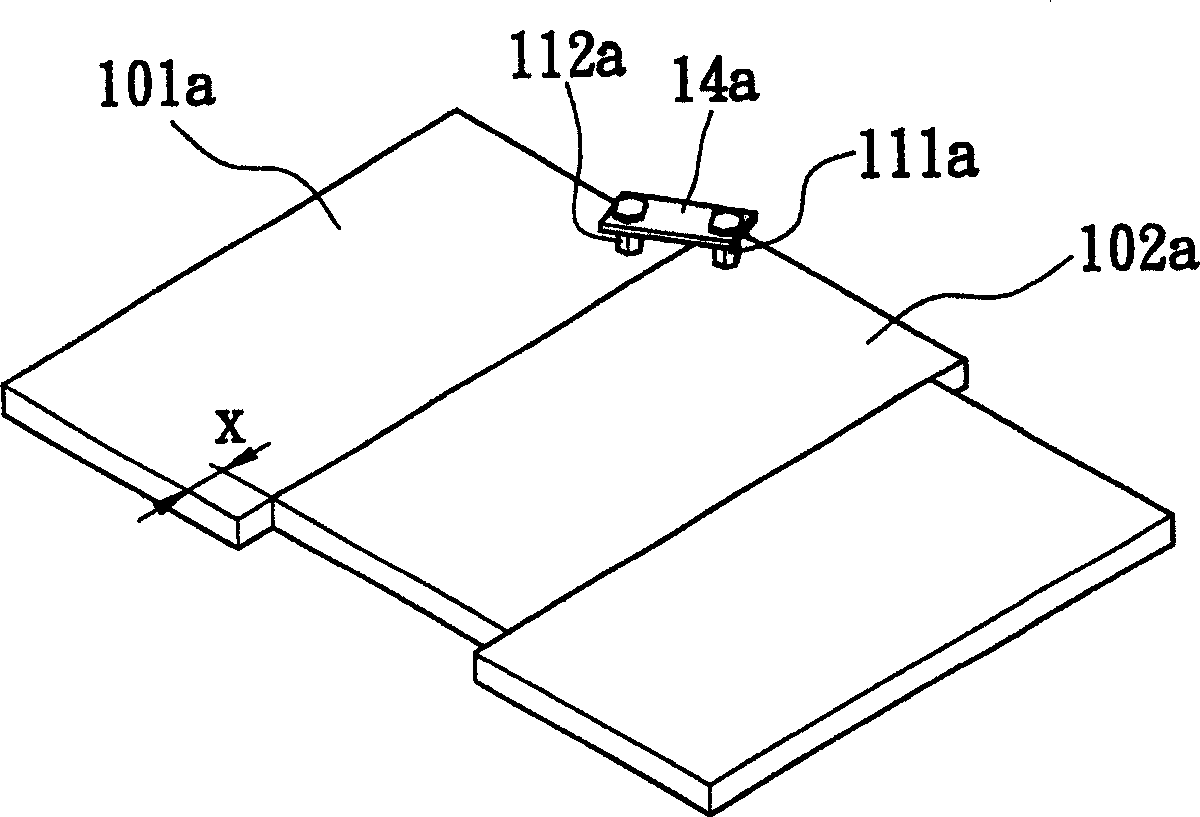

[0043] Please refer to figure 2 As shown, it is the first embodiment of the circuit board clamping device of the present invention. In order to achieve a uniformly displayed light-emitting diode display screen, it includes a plurality of circuit boards 10 adjacent to each other, which are respectively fixed on the circuit boards 10. Multiple pairs of L-shaped fixing frames 21, at least one U-shaped tenon 22 holding the pair of L-shaped fixing frames 21, are used to forcefully combine two adjacent circuit boards 10; wherein, the circuit board 10 has a set The information display surface (not shown) of the light-emitting diode matrix, and the holding surface 101 relative to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com