Method for production of 110KV class XLPE cable insulation material

A technology for cable insulation and production methods, which is applied in the direction of conductor/cable insulation, insulators, organic insulators, etc., can solve problems such as affecting electrical properties, increasing impurity content, and insufficient melting of antioxidants, so as to improve the electrical properties of products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

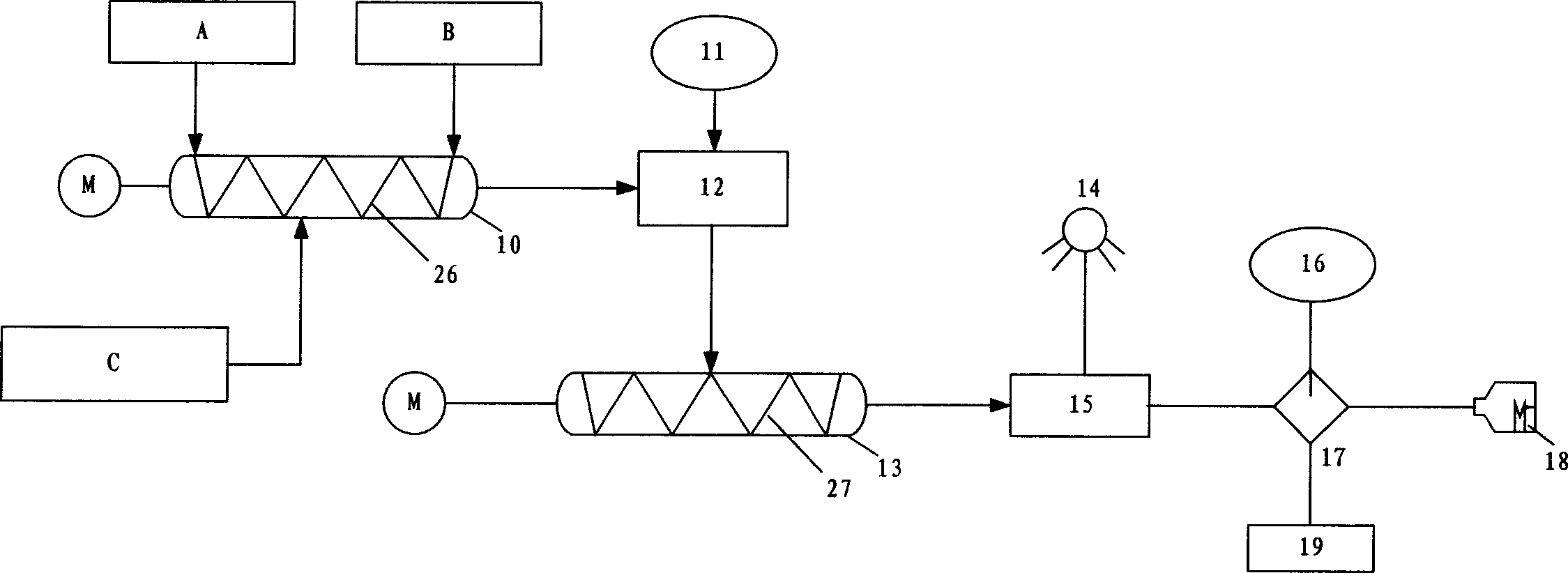

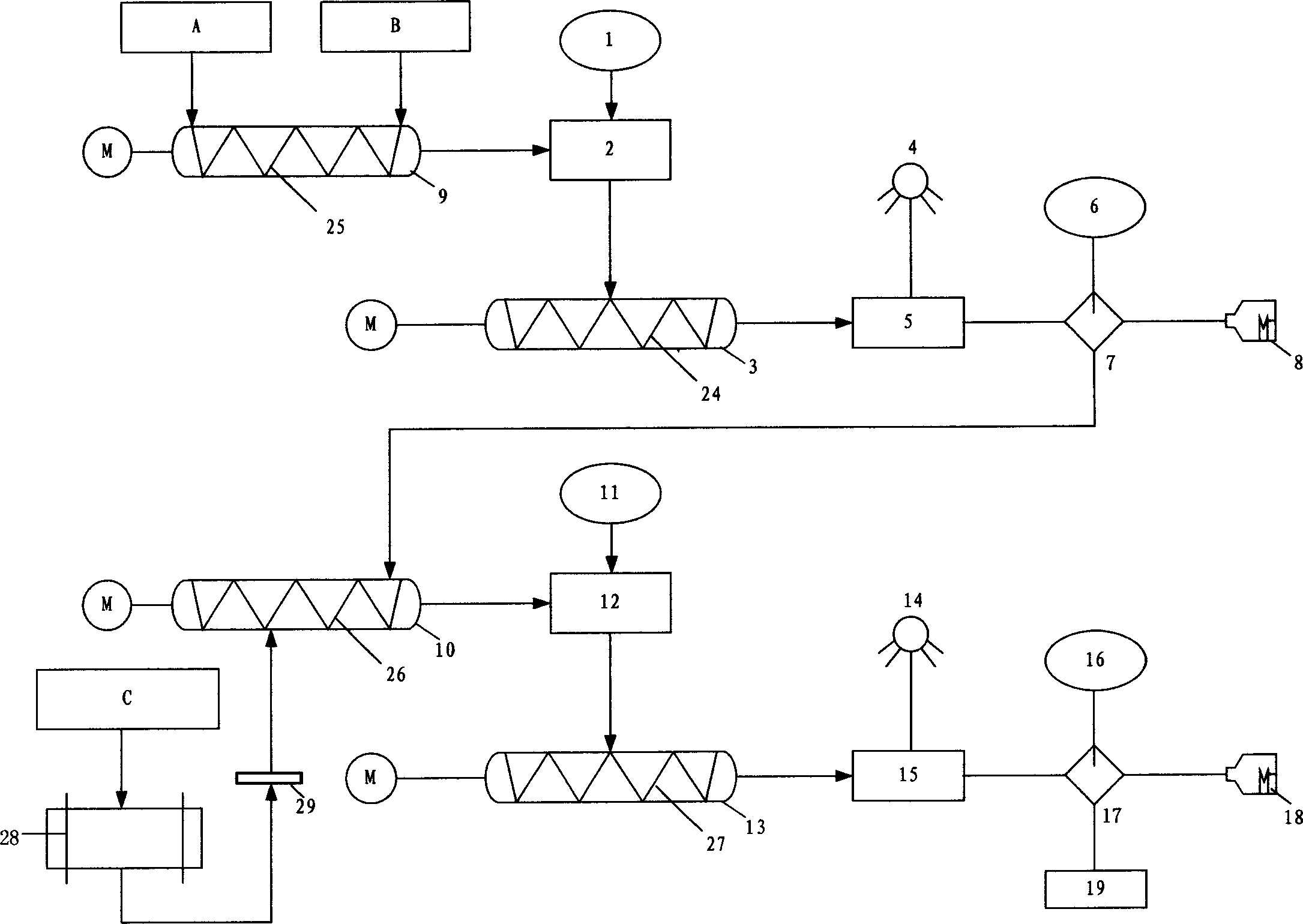

[0037] refer to figure 2 , a kind of production method of 110KV class XLPE cable insulating material of the present invention, it first mixes anti-oxidant and low-density high-pressure polyethylene, after carrying out certain process to it, then becomes liquid state when being heated to 40 ℃ and has been The filtered cross-linking agent dicumyl peroxide (DCP) is mixed according to the production process flow when producing 10KV and 35KV grade XLPE. The specific steps are:

[0038] (1) After weighing the particulate antioxidant A with a melting point of 150°C and the low-density high-pressure polyethylene (PE) B with a particle diameter of 2 mm, inject them into the mixing barrel 9, wherein the screw 25 mixes the two materials Uniform;

[0039] (2) The mixed material is melted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com