Printed circuit board blind hole quality analysing method

A printed circuit board, quality analysis technology, applied in the direction of mechanically removing conductive materials, measuring devices, instruments, etc., can solve problems such as unsatisfactory and incomplete presentation of laser blind holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

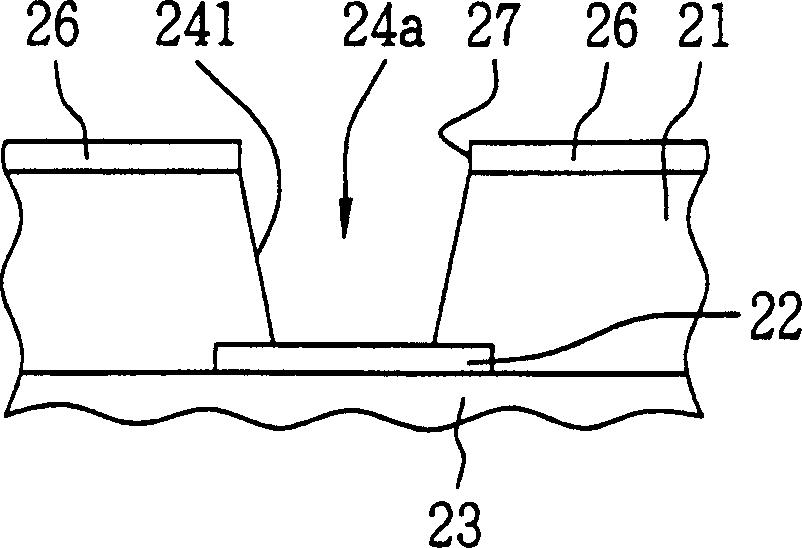

[0024] image 3 is a flowchart of the present invention. As shown in step 31, the original design data of the printed circuit board and the measurement data of the finished product are input, for example: the ideal hole position coordinates (X, Y) of the design, the hole position coordinates (Xo', Yo') of the measured copper window, the measured The pad hole position coordinates (Xp i ', Yp i ′) (i is the number of pads), the designed copper window radius r o , Measured copper window radius r o ′, the designed pad integration radius r p , The measured pad average radius r p ′, the designed hole roundness P, the measured hole roundness P′2 of the copper window, the measured pad hole roundness P′3, the area and coordinates of the residual glue and other data. Then proceed to step 32, using the above-mentioned input data to calculate statistical data, for example: the deviation of the hole position (ΔX, ΔY), wherein ΔX=X-Xo' and ΔY=Y-Yo'; copper window and pad Radius deviat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com