Asymmetrical uniform watering nozzles

A uniform water distribution, asymmetric technology, applied in watering devices, horticulture, botanical equipment and methods, etc., can solve the problem of uneven distribution of water, avoid mutual interference, and have broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

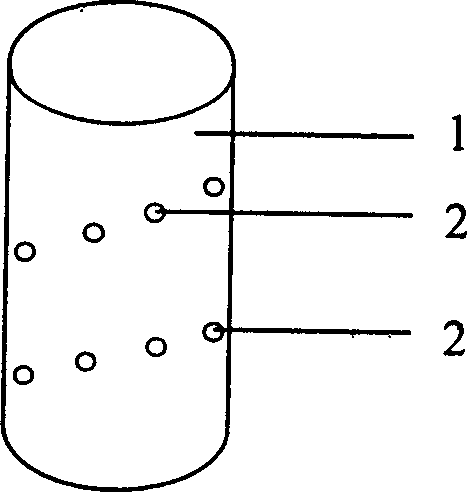

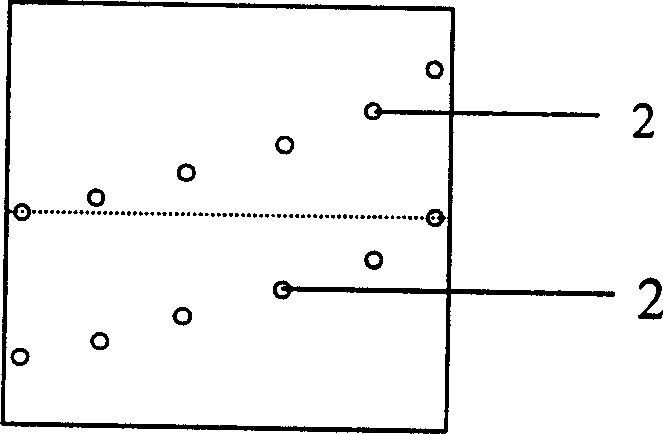

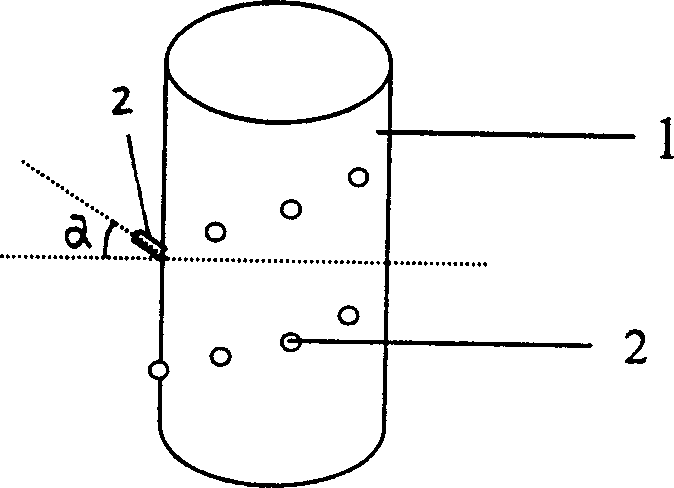

[0015] The present invention is composed of several nozzles 2 installed on a nozzle 1, each nozzle 2 works independently and does not affect each other, each nozzle is equipped with a resistance net with different local resistance, and the distribution of the nozzles on the nozzle is spiral ( Such as figure 1 ), the elevation angle α of nozzle 2 is different. Further illustrate the present invention by implementing example below:

[0016] Working water head with nozzle h p =10m, take 20 nozzles as an example. The local resistance head formed by the resistance network is h i , the range of the nozzle is R, and the elevation angle of the nozzle is α, regardless of the height of the nozzle from the ground. The nozzle number is 1 from the top of the nozzle downwards # ,2 # 、3 # ,...,20 # , when the nozzle does not rotate, the theoretical calculation is as follows:

[0017] 1 # alpha 1 =30° h i1 =0.0m d 1 =4.0mm then V 1 =14.0m / sR 1 =17.3mQ 1 =0.63m 3 / h

[0018...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com