Linear motor

A linear motor, linear guide technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems affecting the control performance of the linear motor, reduce the running stability of the motor, etc., to promote practical application, weaken the cogging reluctance effects, effects with high dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The implementation status of the present invention will be further described below in conjunction with the accompanying drawings.

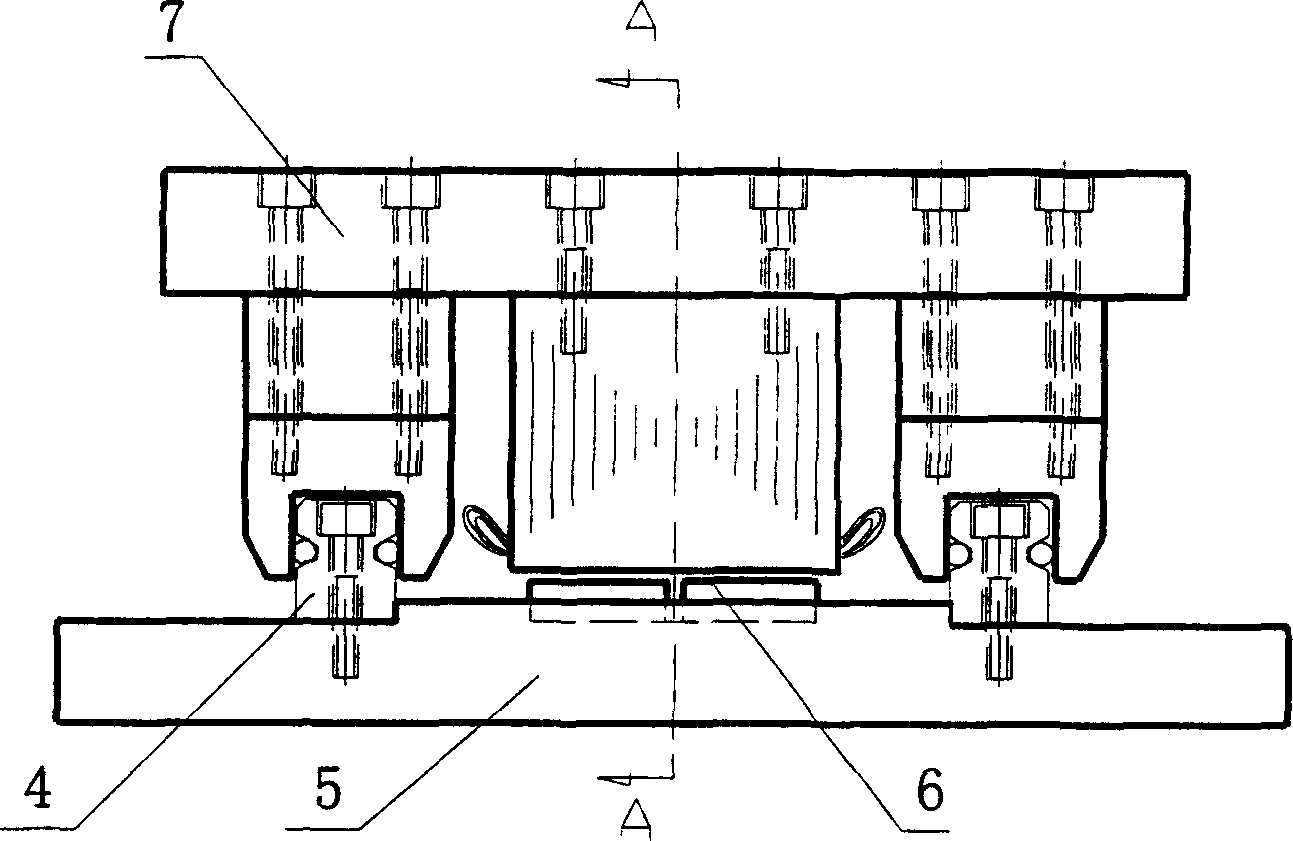

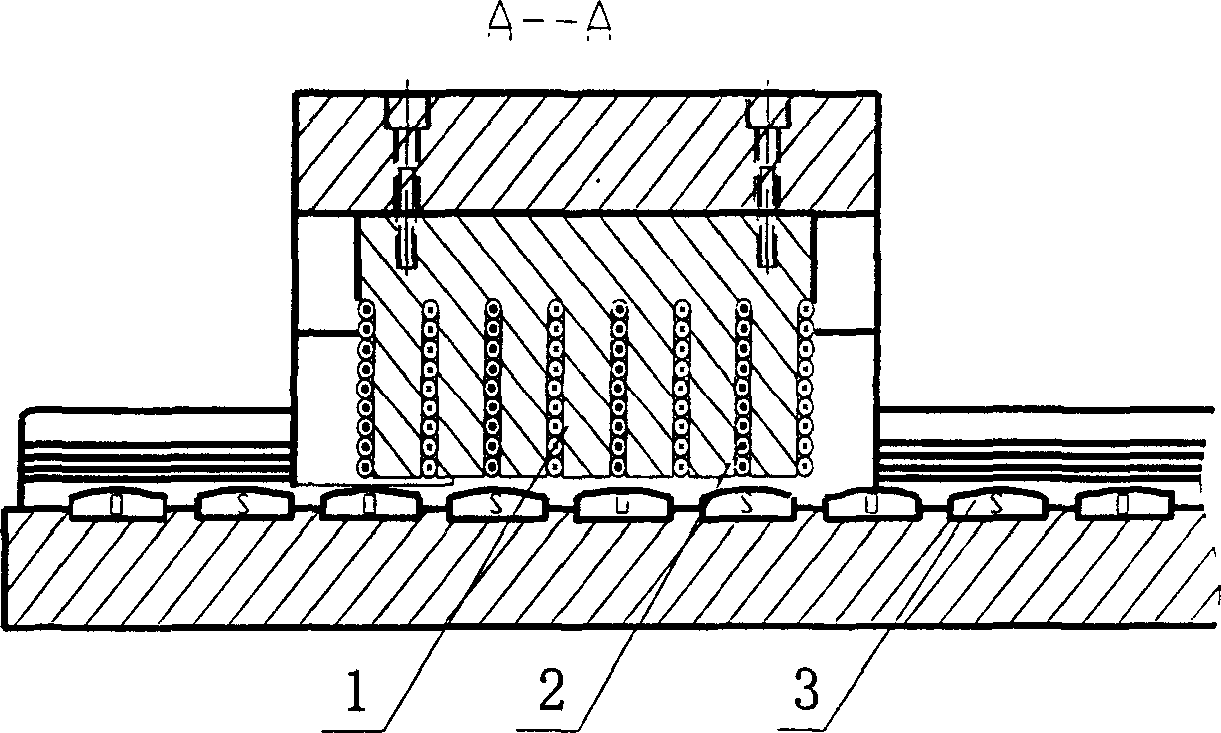

[0013] Such as figure 1 and figure 2 As shown, the mover includes: mover iron core 1, coil winding and tooth slot 2, slide table top 7; the stator includes: magnetic steel 3, linear guide rail 4, base 5; there is an air gap between the mover and the stator 6.

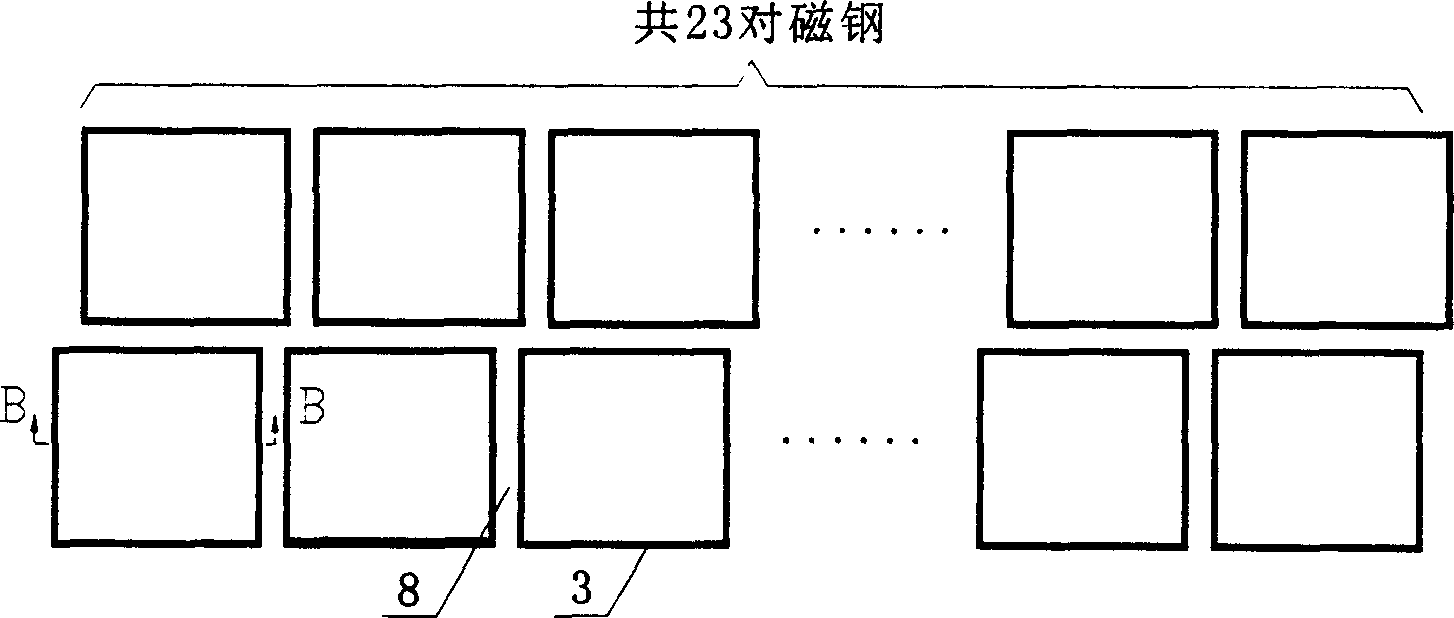

[0014] Such as image 3 The stator of the linear motor shown uses magnets with dislocation distribution. In the figure, there are 3 magnets and 8 gaps between the magnets. The magnets are divided into two rows, and the two rows of magnets are offset by 1 slot width. Thereby, the sudden change of the magnetic field can be reduced, so as to weaken the influence of the reluctance effect and alleviate the thrust instability problem of the motor during the motion. The optimized design of the upper part of the cross-section of the magnetic steel is arc-shaped, so that the air gap magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com