Vibratory cotton basket special for coiling machine

A lapping machine and cotton box technology, applied in winding mechanism, textile and paper making, fiber processing, etc., can solve the problems of high power consumption, complex structure, high cost, etc., save floor area, improve cotton yarn quality, reduce noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

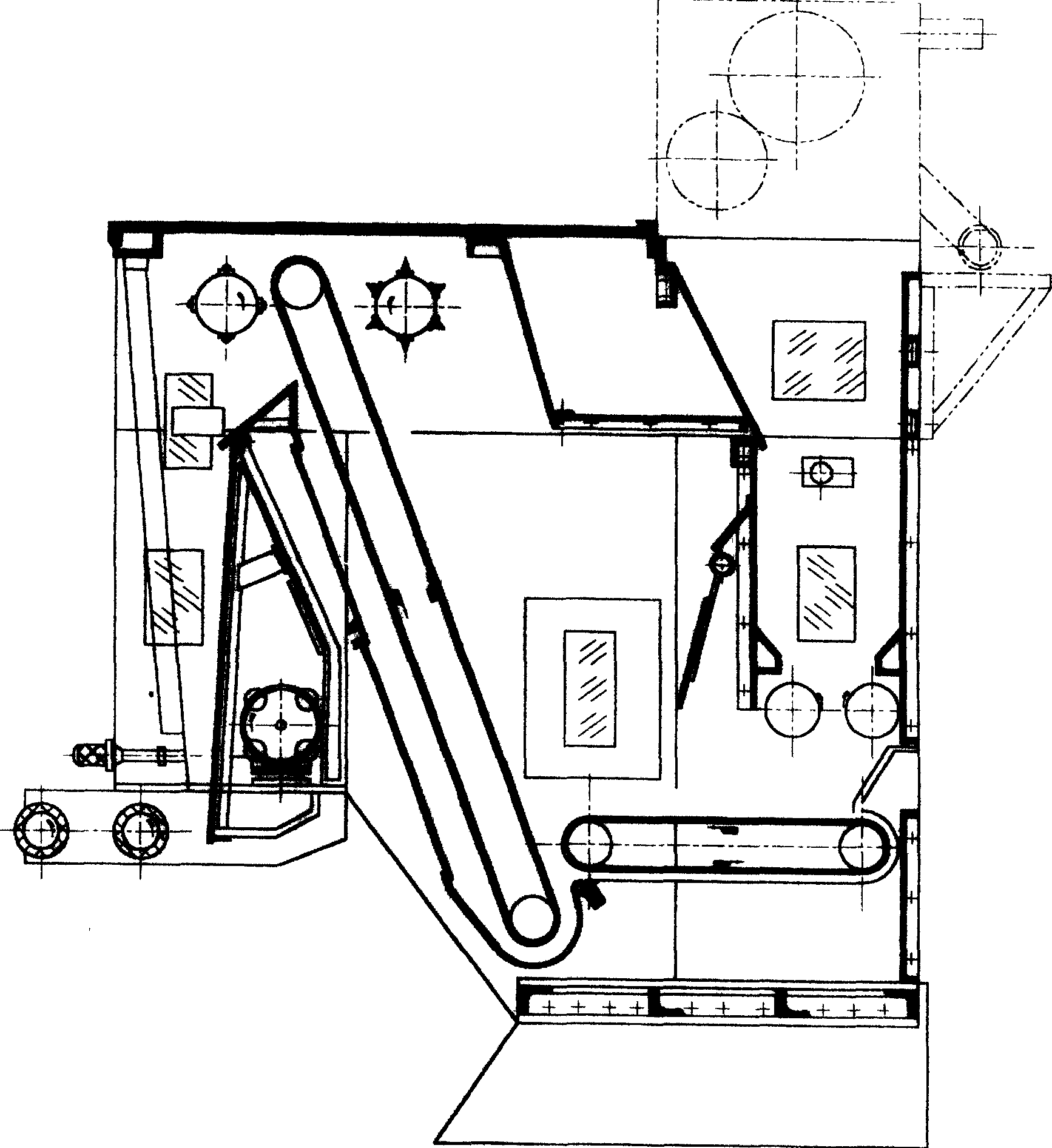

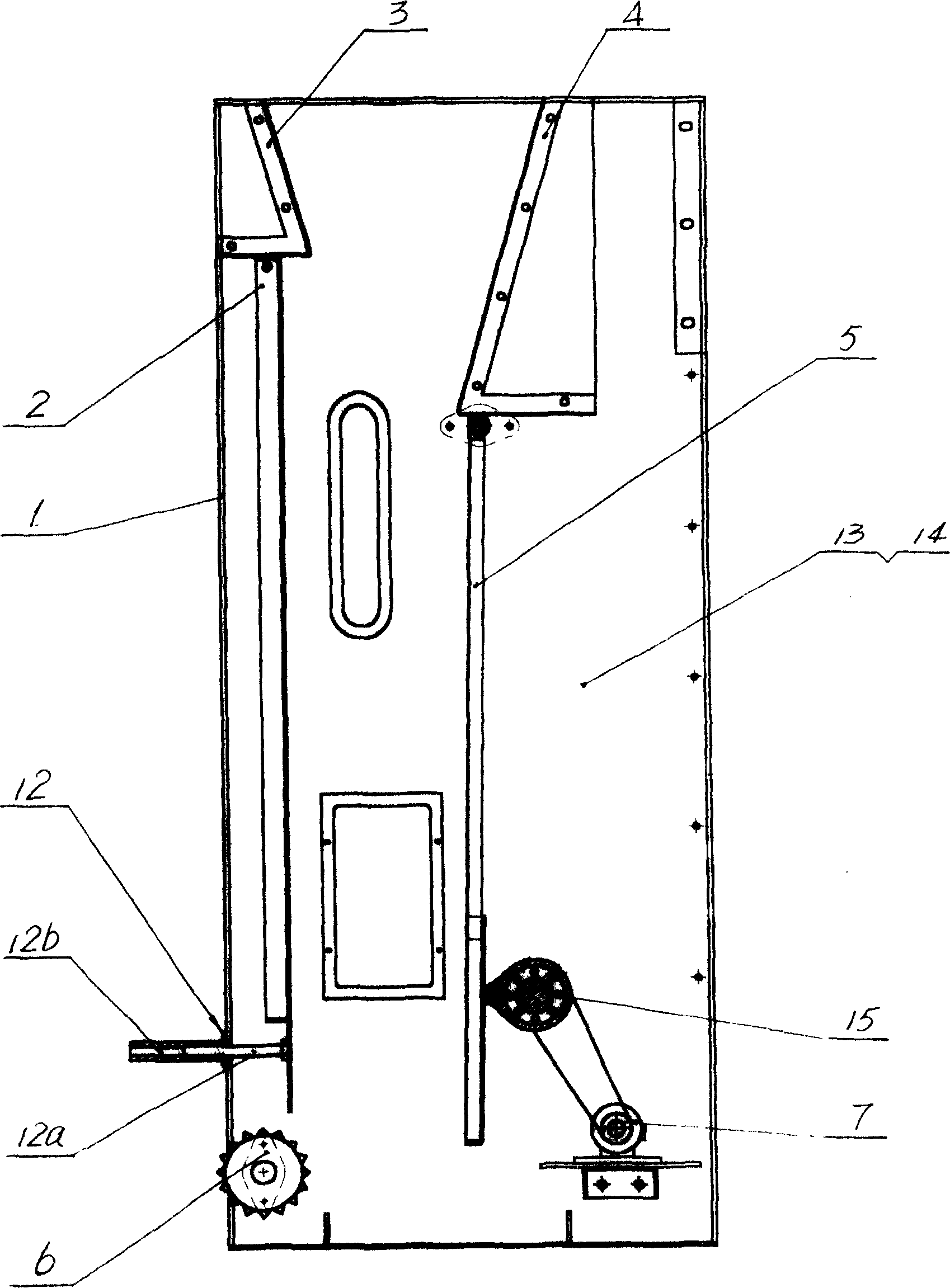

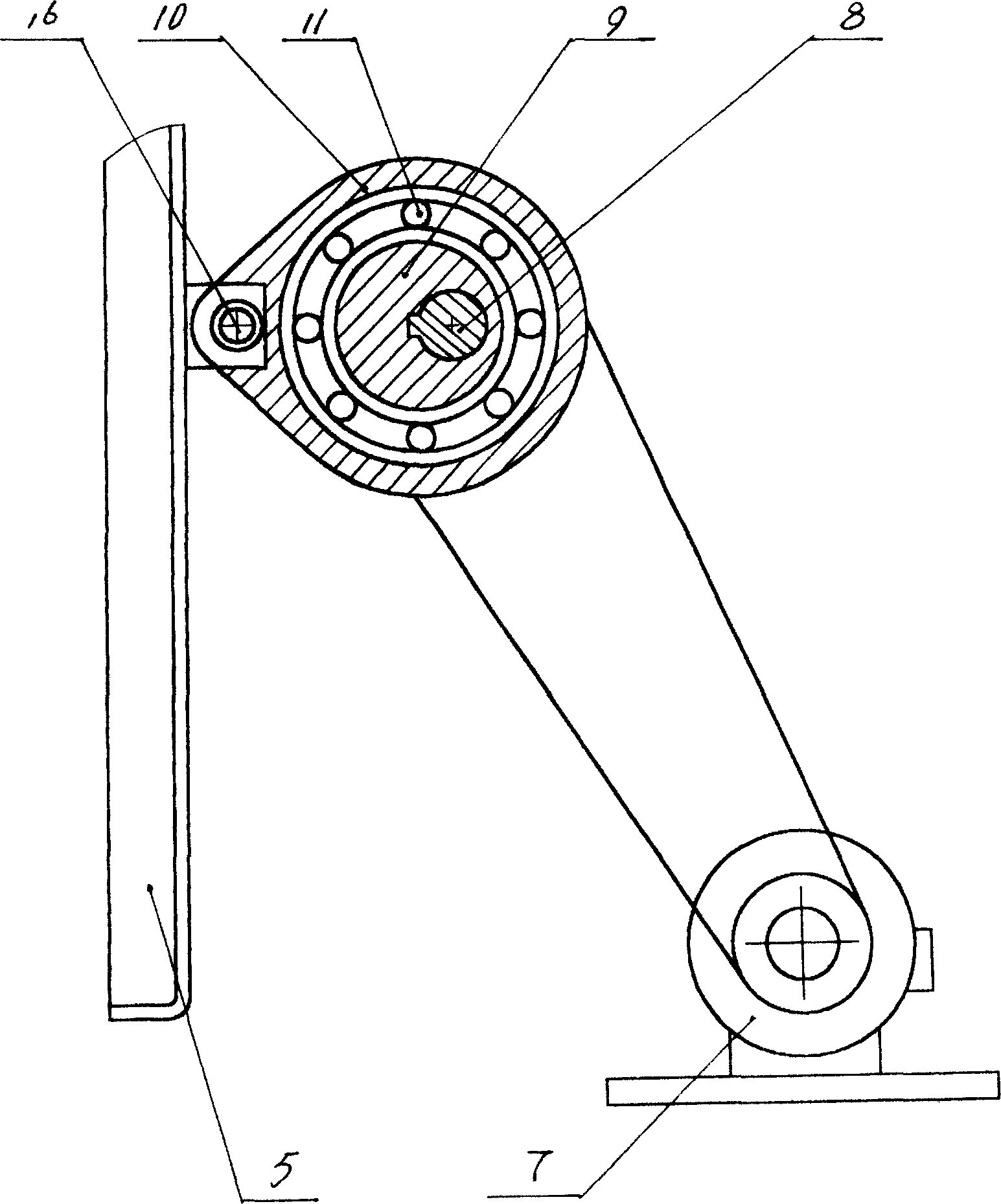

[0013] The special vibrating cotton box for lapping machine described in the present invention is composed of cotton box shell 1, transparent front baffle 2, cotton inlet front baffle 3, cotton inlet rear baffle 4, vibrating plate 5, cotton outlet roller 6 and swing mechanism Composed of 15, the cotton-feeding front baffle 3 and the cotton-feeding rear baffle 4 are fixed on the upper port of the cotton box housing 1, and the upper end of the transparent front baffle 2 is rotatably connected to the lower end surface of the cotton-feeding front baffle 3. An adjustment device 12 is provided between the lower end of the front baffle 2 and the cotton box shell 1. The adjustment device 12 is composed of a screw rod 12a fixed on the transparent front baffle 2 and an adjustment nut handle 12b, which can be adjusted by turning the adjustment nut handle 12b. Adjust the inclination angle of the transparent front baffle 2; the upper end of the vibrating plate 5 is installed on the cotton b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com