Dust collector expansion pipe

A telescopic tube, vacuum cleaner technology, applied in the direction of vacuum cleaners, suction hoses, cleaning equipment, etc., can solve the problems of easy disengagement of positioning rollers, large radial size of locking parts, and unreliable locking, and achieves compact structure and convenient adjustment. , lock reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

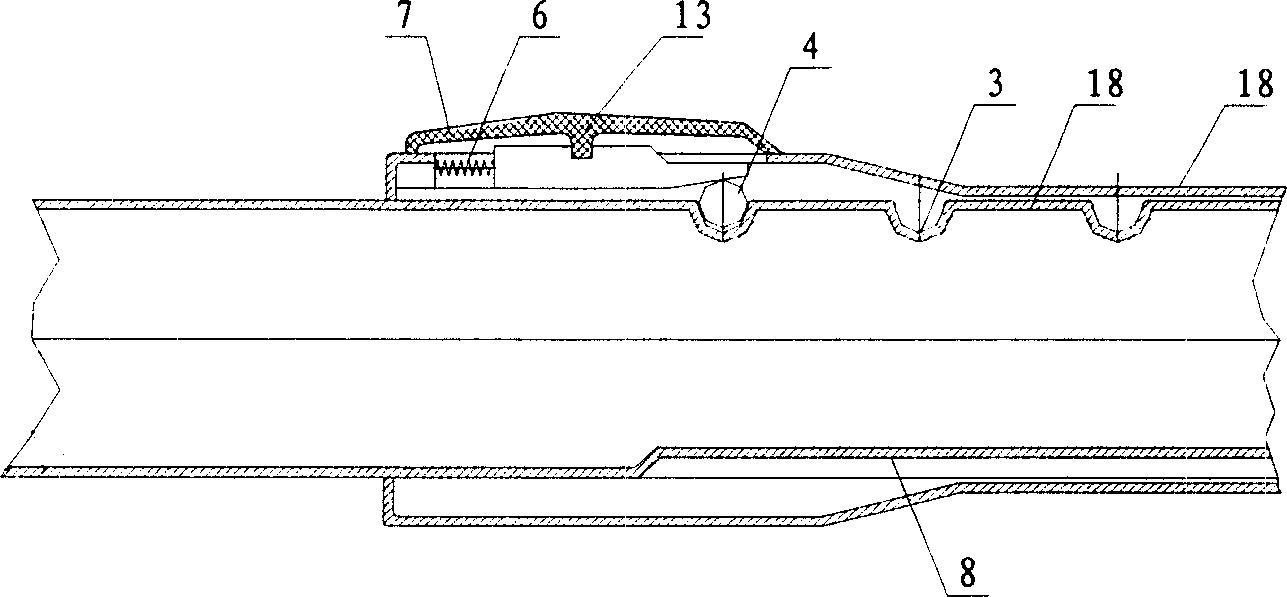

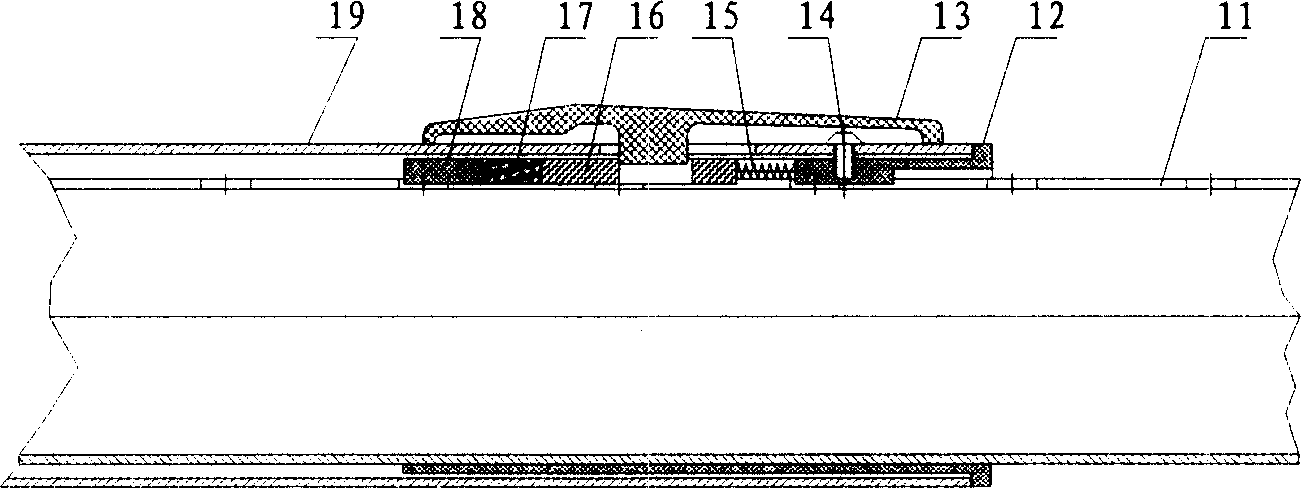

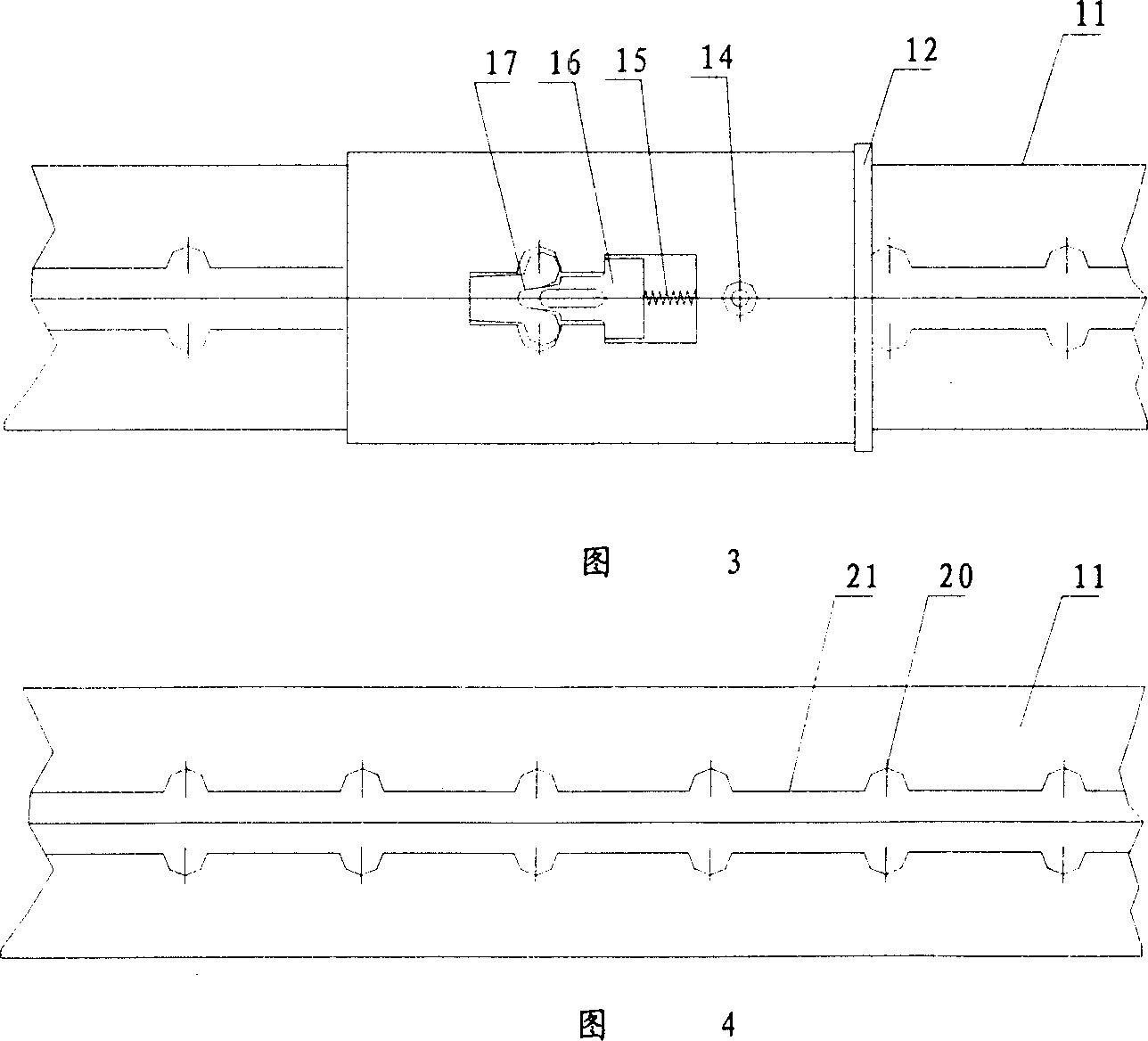

[0014] The telescoping tube of the vacuum cleaner of the present embodiment is as figure 2 , 3, and 4, it mainly consists of the inner tube 11 and outer tube 18 that are nested with each other, the joint sleeve 12 that is fixedly connected to the end of the outer tube by means of screws 14, the elastic V-shaped locking piece 17 and the locking mechanism composed of the latch block 16. . The outer wall of the inner tube 11 is provided with an axial chute 21 as shown in FIG. 4 , and two sides of the axial chute are formed with substantially symmetrical circumferential U-shaped grooves 20 at intervals. The joint cover 12 is shaped on the perforation similar to the envelope shape of the elastic V-shaped locking piece 17 and the latch block 16 . The elastic V-shaped locking plate 17 of the locking mechanism is formed with a symmetrical arc lug matching the U-shaped groove 20, and one end passing through the hole on the joint sleeve 12 falls into the axial slide groove 21, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com