Hydraulic loop of building machinery

A technology for hydraulic circuits and construction machinery, which is applied in the field of hydraulic circuits and can solve problems such as the inability of pressure oil to be supplied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

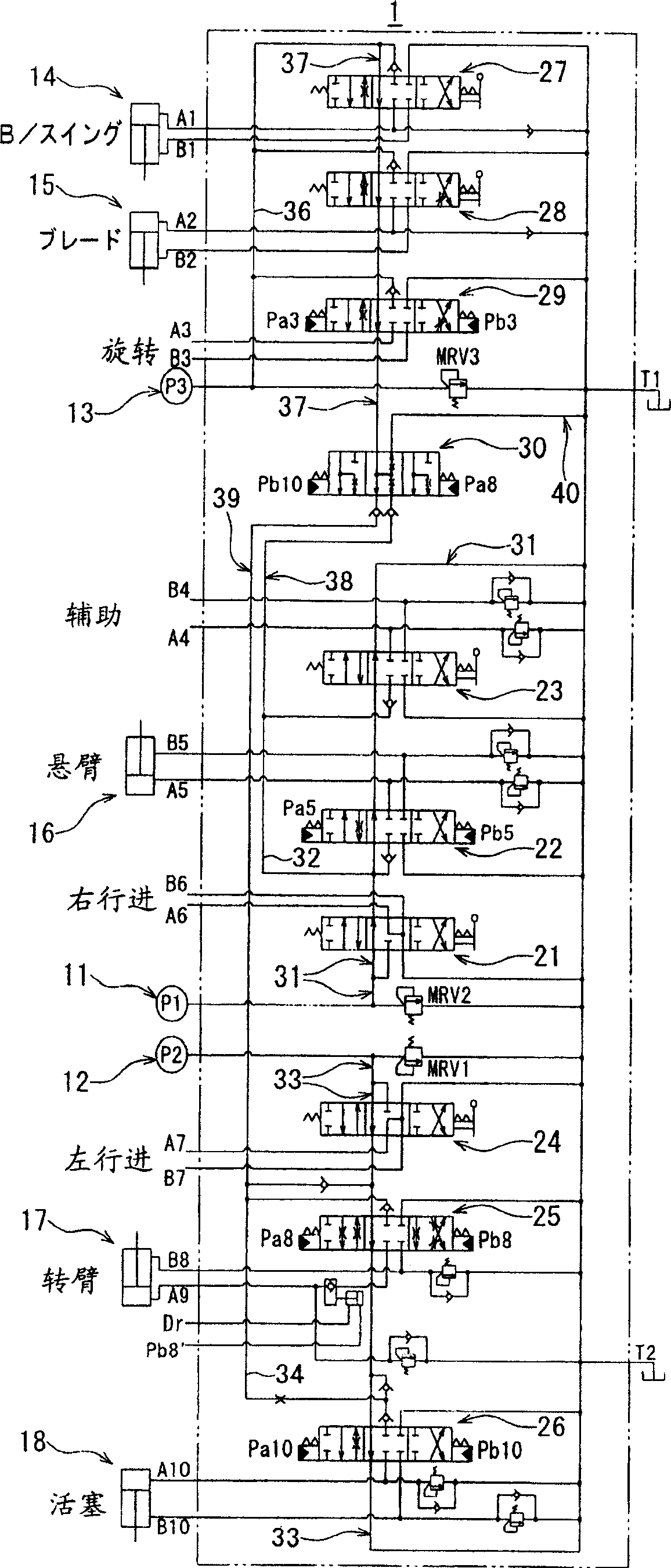

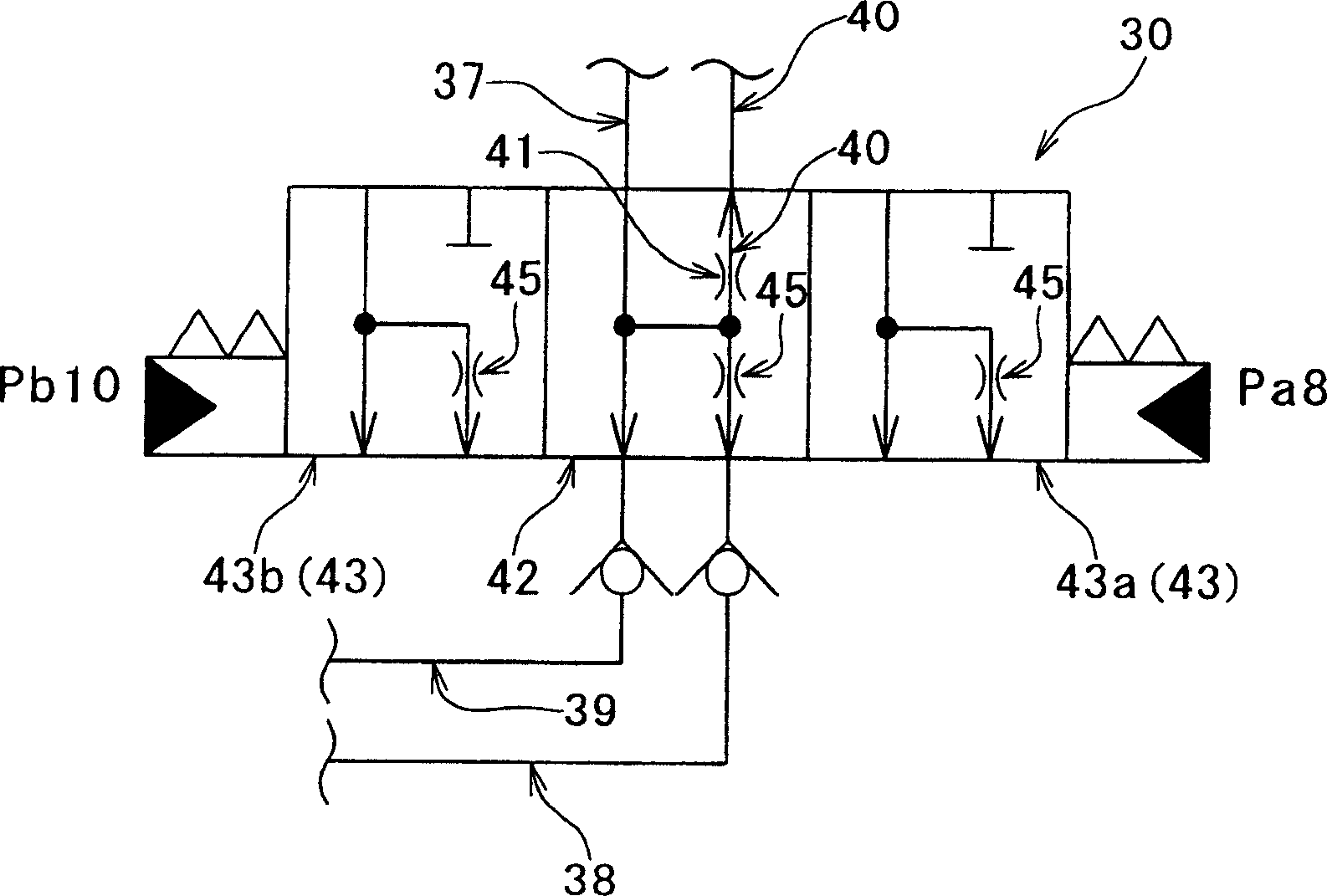

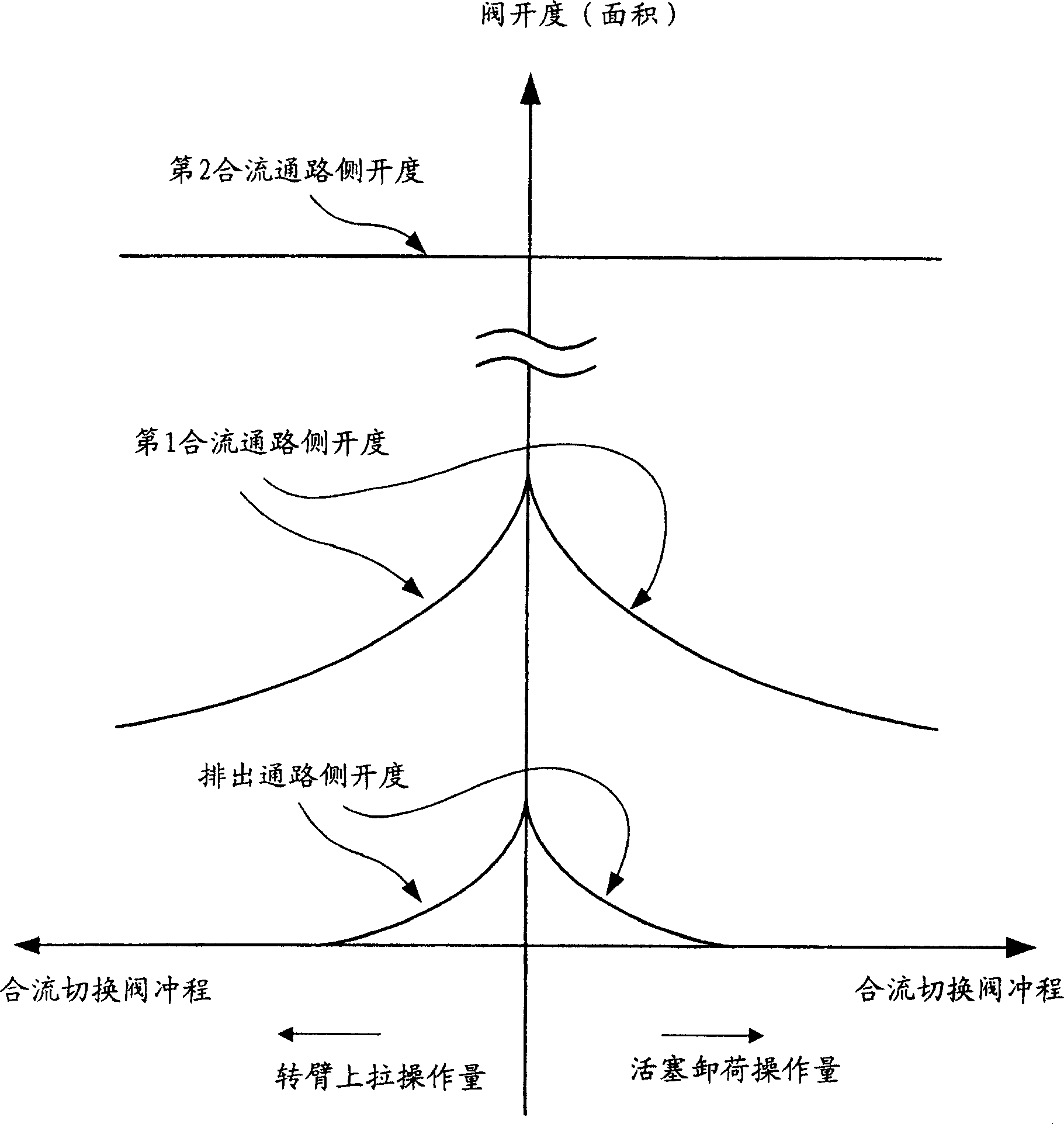

[0023] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. figure 1 It is a figure which shows the hydraulic circuit of the construction machine which concerns on embodiment of this invention. The construction machine to which the hydraulic circuit 1 (hereinafter referred to as the hydraulic circuit 1) of the construction machine is applied is a tracked vehicle equipped with various actuators such as a boom or a boom, and has hydraulic motors for driving these actuators. Or each pressure cylinder. Furthermore, this construction machine is equipped with a first pump 11 (P1), a second pump 12 (P2) and a third pump 13 (P3), and the first pump 11 (P1), the second pump 12 (P2) and the The 3 pumps 13 (p3) supply the pressurized oil to the first to third systems provided in the hydraulic circuit 1, respectively.

[0024] Such as figure 1 As shown, the hydraulic circuit 1 is equipped with: a first system, connected with a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com