Device for detecting absolute rotation angle and torque

A technology of absolute rotation and detection device, which is applied in the direction of measuring device, torque measurement, transportation and packaging, etc., and can solve the problems of larger detection device, non-detection of absolute angle, and larger size of detection device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be described below with reference to the drawings.

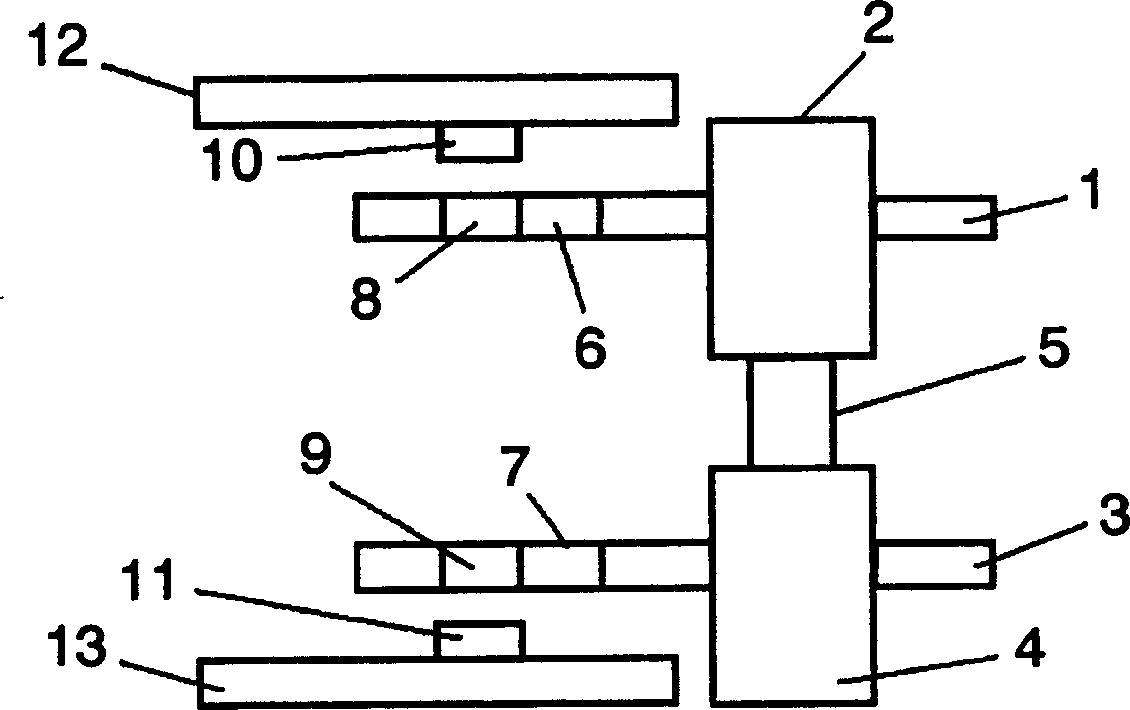

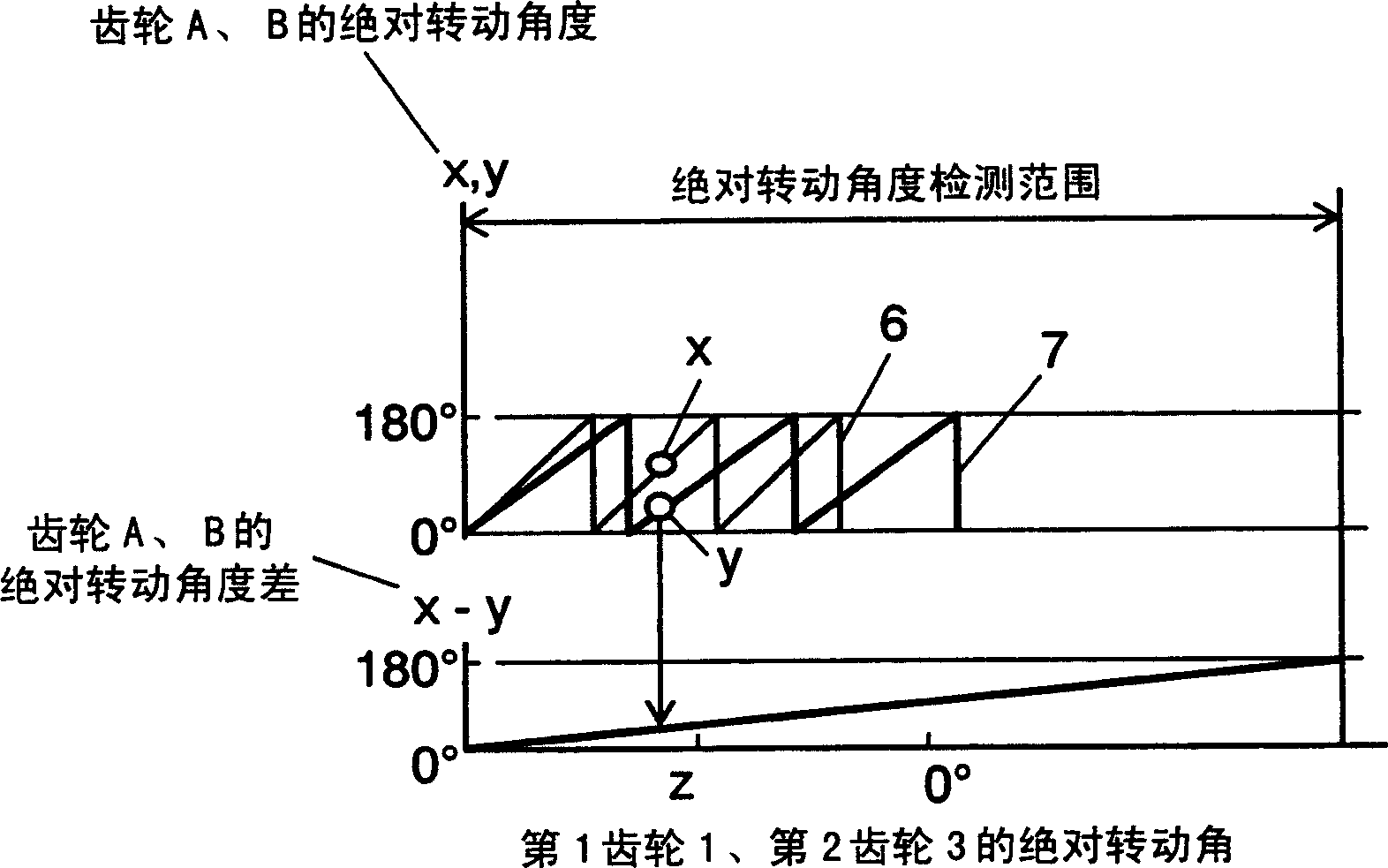

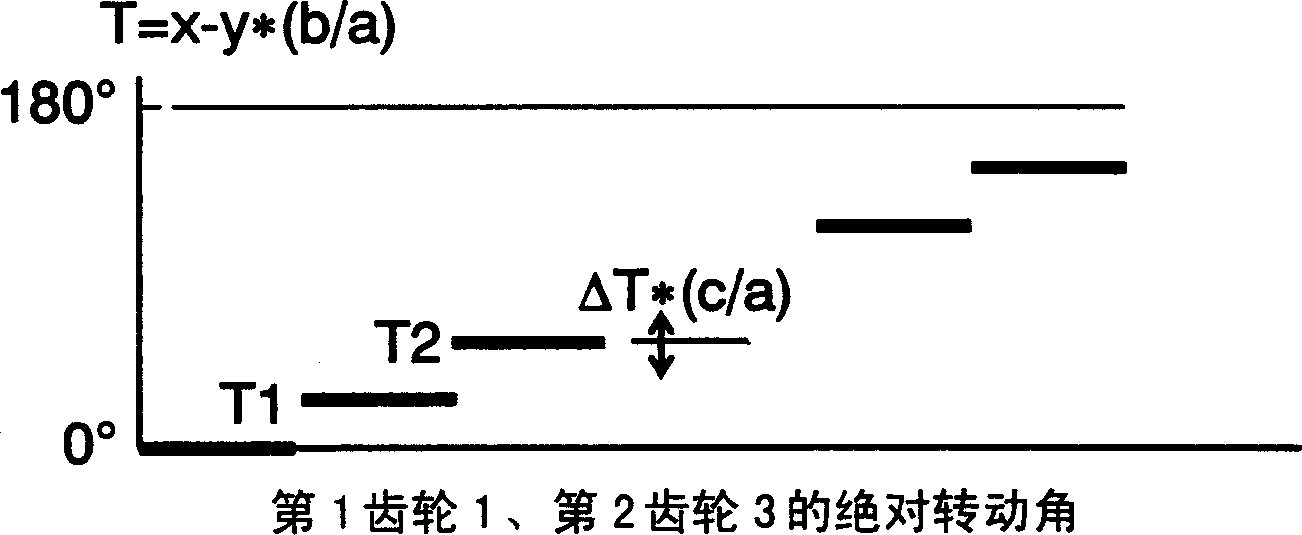

[0014] figure 1 The structure of the absolute rotation angle and torque detection device of this embodiment is shown. The torsion bar unit is composed of an input shaft 2 , a torsion bar 5 , and an output shaft 4 arranged concentrically on the same rigid body. The first gear 1 and the second gear 3 are connected to the input shaft 2 and the output shaft 4 of the torsion bar unit, respectively. The first gear 1 cooperates with gear A6, and the second gear cooperates with B7. The first magnet 8 is provided at the center of the gear A6, and the second magnet 9 is provided at the center of the gear B7. The first magnet 8 and the second magnet 9 are magnetized by one pole pair. The first magnetic detection element 10 mounted on the substrate 12 is arranged at a position facing the first magnet 8 , and the second magnetic detection element 11 mounted on the substrate 13 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com